FENTE FTC Series Single-cylinder Hydraulic Cone Crusher is specifically designed and manufactured to handle heavy-duty and harsh operating conditions, offering enhanced reliability. The equipment features a compact body and powerful crushing capability. With an optimized chamber design, it achieves high crushing efficiency while producing high-quality, well-shaped products.

Users can choose from automatic control, various crushing chamber types, and numerous high-performance features. Each model can be customized by selecting the appropriate crushing chamber type and eccentricity to meet diverse user requirements. It is easy to maintain and offers high operational efficiency.

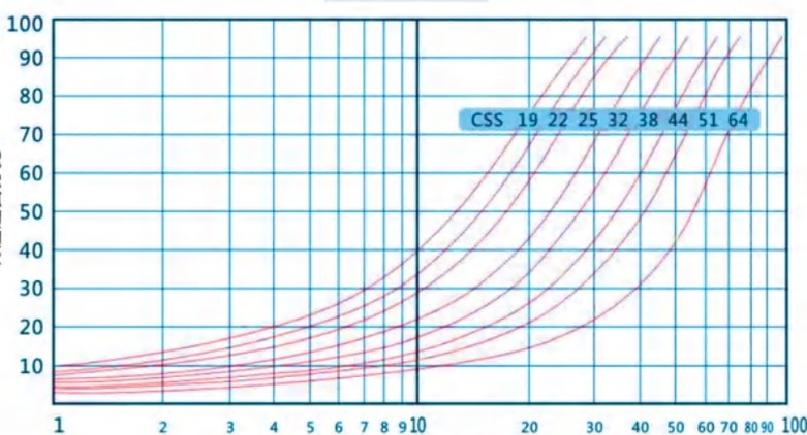

Deep Cavity FTC-S Model Technical Parameters for Three Models

(including processing capacity, feed opening size, motor power, and crushing chamber type)

| FTC-S crushers |

Model | Installed Power | Chamber | Max feeding grain size | Nominalcapacity in t/h with crusher running at css mm | |||||||||||||||

| KW | mm | 19 | 22 | 25 | 29 | 32 | 35 | 41 | 44 | 48 | 51 | 54 | 60 | 64 | 70 | 76 | ||||

| FTC430-S | 185 | EC | 360 | 127 | 35-175 | 142-233 | 158-290 | 162-313 | 175-329 | 180-350 | 195-300 | 203-255 | 210 | |||||||

| C | 300 | 106 | 115-144 | 125-200 | 133-256 | 140-272 | 150-287 | 161-305 | 166-267 | 185 | ||||||||||

| MC | 235 | 90 | 98-125 | 105-168 | 115-215 | 125-235 | 130-247 | 139-248 | 145-277 | 152-245 | 169 | |||||||||

| FTC440-S | 250 | EC | 450 | 266 | 280-356 | 295-443 | 310-561 | 335-598 | 350-526 | 360-457 | ||||||||||

| C | 400 | 221 | 241-299 | 252-382 | 270-485 | 285-515 | 296-447 | 316-399 | 335 | |||||||||||

| MC | 300 | 195 | 211-265 | 229-345 | 245-437 | 257-460 | 273-488 | 285-422 | 304-381 | 321 | ||||||||||

| FTC660-S | 355 | EC | 560 | 352 | 368-462 | 391-586 | 412-721 | 425-858 | 465-931 | 485-977 | 525-1054 | 560-985 | ||||||||

| C | 500 | 383 | 333-424 | 351-622 | 375-751 | 393-785 | 409-826 | 449-891 | 471-824 | 501-635 | ||||||||||

Deep cavity FTC-H type five model technical parameters (including processing capacity, feed inlet size, motor power, crushing cavity type).

|

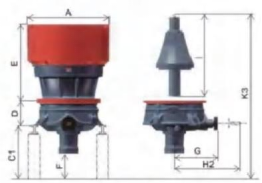

Size (mm) |

FTC430-S |

FTC 440-S |

FTC660-S |

FTC430-H |

FTC440-H |

FTC660-H |

FTC870-H |

FTC880-H |

|

A |

φ1635 |

φ2000 |

φ2800 |

φ1360 |

φ1540 |

φ2104 |

02660 |

φ2900 |

|

B |

3485 |

4075 |

5100 |

2992 |

3410 |

4215 |

5475 |

6450 |

|

C1 |

1125 |

1300 |

1600 |

1125 |

1300 |

1600 |

2200 |

2870 |

|

D |

665 |

745 |

860 |

655 |

745 |

860 |

1228 |

1190 |

|

E |

1705 |

2030 |

2640 |

1212 |

1365 |

1755 |

2045 |

2400 |

|

F |

422 |

452 |

631 |

422 |

452 |

631 |

998 |

1150 |

|

G |

1061 |

1280 |

1497 |

1061 |

1280 |

1497 |

1824 |

1960 |

|

H2 |

1705 |

1900 |

2156 |

1705 |

1900 |

2156 |

2850 |

3100 |

|

I |

2050 |

2420 |

2895 |

1688 |

1985 |

2344 |

3095 |

3500 |

|

K3 |

1250 |

4930 |

5355 |

3570 |

4000 |

1835 |

6600 |

7700 |

|

Weight |

12000kg |

19300kg |

35700kg |

9200kg |

14300kg |

26800kg |

49800kg |

55000kg |

|

Power(kW) |

185 |

250 |

355 |

160 |

220 |

315 |

600 |

630 |

|

Control System |

Fully automatic monitoring |

Fully automatic monitoring |

Fully automatic monitoring |

Fully automatic monitoring |

Fully automatic monitoring |

Fully automatic monitoring |

Fully automatic monitoring |

Fully automatic monitoring |

S-shaped crushing force

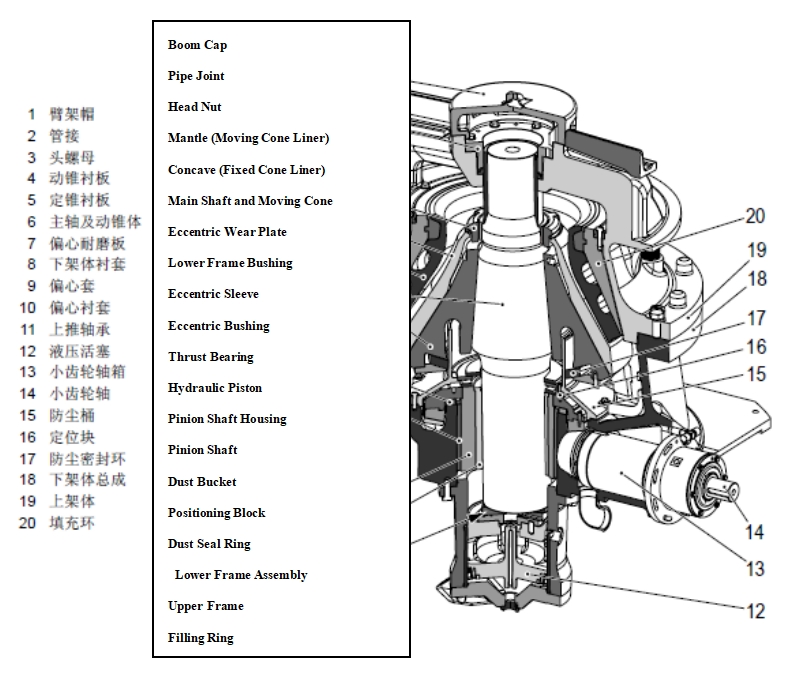

Product structure and working principle

FENTE FT Series Cone Crusher primarily consists of components such as the lower frame, eccentric sleeve, dust-proof device, drive shaft, main shaft, upper frame, adjustment cylinder, and liners. Its simple structure allows for easy maintenance and assembly/disassembly.

The optimized combination of crushing speed, eccentricity, and crushing chamber design delivers higher output, better product quality, and broader applicability. The specific structure is shown in the diagram below.

Working Principle:

The motor drives the transmission shaft via a V-belt, and power is transmitted through a horizontal shaft that rotates the eccentric sleeve via bevel gears. The eccentric sleeve, in turn, drives the main shaft to rotate, causing the moving cone to perform a gyratory motion. This motion creates a crushing action between the mantle (crushing wall) and the concave (bowl liner).

Materials are fed into the feed hopper via the feeding device and enter the crushing chamber. After being crushed, the materials are discharged through the lower section and collected via the discharge chute.

Product Features

1.High-Performance Frame Design:

The upper and lower frames are made of high-performance ZG20Mn cast alloy, connected via a conical connection. During the crushing process, the frames form an integrated structure with a flexible foundation, reducing the load requirements on the base.

2.Durable Main Shaft and Moving Cone:

The main shaft is made of 42CrMo, and the moving cone is cast from manganese alloy. This design ensures excellent stress distribution, stability, and reliability, reducing the likelihood of bending or breaking. It also extends the service life of the components.

3.Simple Adjustment of Discharge Opening:

The discharge opening can be adjusted easily and dynamically, with real-time adjustment and display capabilities.

4.Optimized Crushing Chamber:

The chamber design increases output. Additionally, by replacing the liners, different chamber types can be achieved within the same machine structure. Multiple eccentricities are available to meet diverse processing requirements.

5.Effective Overload and Iron Protection:

Overload and iron protection are simple and efficient, achieved by adjusting the pressure of a single accumulator. This allows sensitive and responsive vertical movement of the moving cone for protection.

6.Excellent Ore Throughput:

The optimized apex angle of the moving cone improves the handling of ores containing water and mud, ensuring excellent material flow through the crushing chamber.

单缸液压圆锥破碎机.png)