Working Principle

The material is feed into crusher through a feed hopper. There is a feed choke plate to control the volume into motor. This choke plate is control by hydraulic system and easy to use The material falls down to feed tube by gravity action and continuously falls into rotor. The rotor is driven by a belt pulley which is connected with electrical motor. When the material enters into rotor, it is speeded up to 45-62m/s by function of centrifugal force. Then the material will fly out from rotor through designed moving path. The ejected material will hit the material piled inside crusher cavity,and violent crash will happen This high speed 'Rock to Rock' crash causes impact, cleavage and attrition of the feed material.

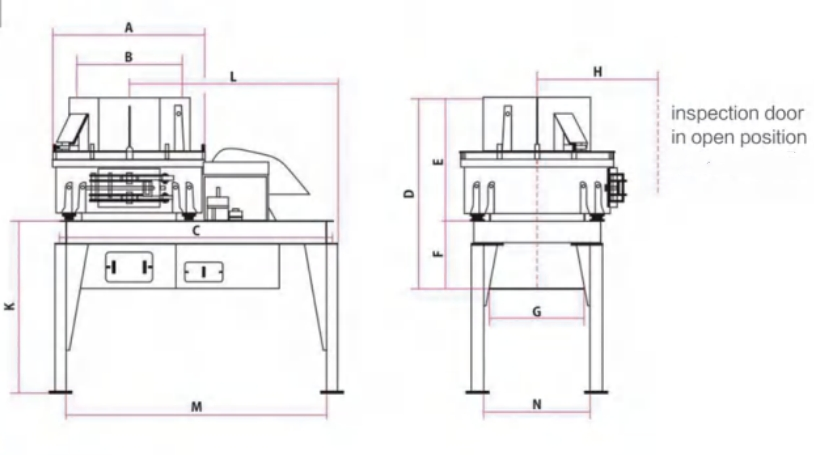

Single Motor Dimensions

| Dimensions(mm) | FTSI 1000 | FTSI 2000 | FTSI 3000 | FTSI 4000 |

| A | 1730 | 2040 | 2040 | 2444 |

| B across flats | 902 | 1016 | 1016 | 1216 |

| C | 3166 | 3626 | 3626 | 3750 |

| D | 2002 | 2553 | 2553 | 3061 |

| E | 1212 | 1648 | 1648 | 2130 |

| F | 790 | 905 | 905 | 941 |

| G | 1070 | 1250 | 1250 | 1420 |

| H | 1840 | 1912 | 1912 | 2090 |

| K | 2331 | 2970 | 2970 | 3076 |

| L | 2427 | 2757 | 2757 | 2806 |

| M | 2978 | 3438 | 3438 | 3562 |

| N | 1170 | 1430 | 1430 | 1480 |

| Weight(kg) | 6000 | 9500 | 9500 | 11780 |

| Max.feed size(mm) | 40 | 50 | 50 | 55 |

| Capacity range(t/h) | 10-50 | 51-121 | 122-192 | 193-250 |

| Rotor rpm range | 1565-2100 | 1380-1980 | 1390-1970 | 1400-1680 |

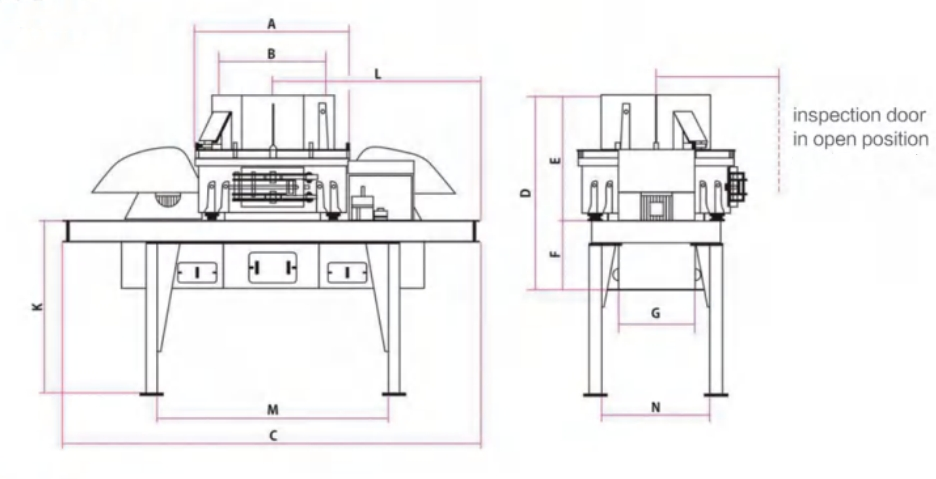

Dula Motor Dimensions

| 尺寸Dimensions(mm) | FTSI 4200 | FTSI 5200 |

| A | 2444 | 2444 |

| B across flats | 1216 | 1216 |

| C | 5500 | 5500 |

| D | 3061 | 3071 |

| E | 2130 | 2130 |

| F | 931 | 941 |

| G | 1420 | 1420 |

| H | 2090 | 2090 |

| K | 3090 | 3090 |

| L | 2750 | 2750 |

| M | 3018 | 3018 |

| N | 1500 | 1500 |

| Weight(kg) | 14830 | 14830 |

| Max.feed size(mm) | 55 | 55 |

| Capacity range(t/h) | 255-450 | 451-600 |

| Rotor rpm range | 1400-1680 | 1400-1680 |

反击式破碎机.png)

反击式破碎机3.png)

反击式破碎机3.png)

反击式破碎机1.png)