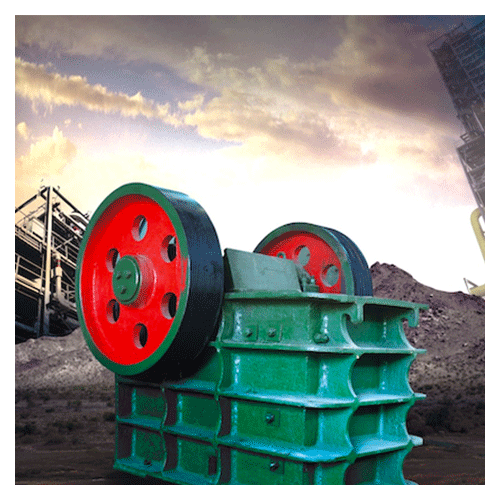

In order to solve the problems of low production efficiency and hard rack crushing of existing jaw crushers on the market, Shenyang Fente Mining Machinery Technology Co., Ltd. has successfully launched FTC series jaw crushers based on years of production experience and production line engineering service experience. The advantages of this equipment, such as simple structure design, high crushing efficiency, low failure rate and energy consumption, make it the most ideal coarse crushing equipment in the domestic and foreign markets. It is also the strongest equipment in the gravel production process.

Excellent throughput: change the traditional Y-type feeding, bulk logistics and hard materials, and crush the materials by laminating.effectively ensuring the crushing ratio and crushing rate.

Strong crushing ratio: LanTe C series jaw crusher is famous for its strong dynamic jaw movement and long eccentricity at the bottom of the crushing chamber. Eccentricity gradually increases from top to bottom, and reaches the maximum value at the bottom, thus increasing the productivity and crushing ratio, so as to obtain higher production capacity and meet the demand for product grain size.

Convenient maintenance: The easily warn parts of the C series jaw crusher are designed to facilitate the replacement of parts or the protection of wearing materials, so the maintenance is extremely convenient, These unique designs can prevent the wear of expensive key components, shorten the maintenance time, and thus obtain more normal operation time.

Performance advantages

- The moving jaw assembly is made of high-quality cast steel, and the integral cast steel bearing pedestal can ensure the reliability and durability of equipment operation.

- Forged heavy eccentric shaft and four larger and more durable eccentric shaft bearings, with higher bearing capacity and effective labyrinth seal, greatly extend the service life of the eccentric shaft.

- The crushing chamber is designed with large centrifugal force and steep elbow inclination angle,which makes the effective stroke at the bottom of the crushing chamber larger and the crushing performance better.

- The tooth shape and thickness of jaw plate have been optimized, and the appropriate manganese steel alloy material has been selected, which not only increases the output but also reduces the use cost.

- The centralized lubrication device configured makes the lubrication of the crusher bearing more convenient and fast.

- The double wedge adjustment system is more robust, simple, safe and fast. If the hydraulic drive adjustment device is selected, it is easy to realize the automation of equipment production.

- The integrated motor base can reduce the installation space of the crusher and the length of the V-belt, adjust the tension of the V-belt of the motor, and increase the service life of the V-belt.

Specifications and Performance Parameters

| Model | Feeding opening size(mm) | Max feeding size(mm) |

Discharge range opening(mm) | Eccentric shaft speed(r/min) | Capacity (t/h) |

Power (kw) | Dimesion(L×WxH) (mm) | Weight (t) |

| LTC80 | 510×800 | 420 | 40-75 | 350 | 65-380 | 75 | 2577×1526×1750 | 9.25 |

| LTC96 | 580×930 | 460 | 60-175 | 330 | 120-455 | 90 | 2880×1755×1460 | 1187 |

| LTC100 | 760×1000 | 640 | 70-200 | 260 | 150-545 | 110 | 3670×2420×2490 | 23.3 |

| LTC106 | 700×1060 | 580 | 70-200 | 280 | 155-580 | 110 | 3320×2030×2005 | 17.05 |

| LTC110 | 850×1100 | 730 | 70-200 | 230 | 190-625 | 160 | 3770×2385×2750 | 29.5 |

| LTC116 | 800×1150 | 680 | 70-200 | 260 | 170-600 | 132 | 3600×2400×2790 | 21.5 |

| LTC125 | 950×1250 | 800 | 100-250 | 220 | 290-845 | 160 | 4100×3010×3140 | 43.91 |

| LTC140 | 1070×1400 | 920 | 125-250 | 220 | 385-945 | 200 | 4400×3010×3140 | 54.01 |

| LTC145 | 1100×1400 | 950 | 125-275 | 220 | 400-1070 | 200 | 4600×3110×3410 | 63.19 |

| LTC160 | 1200×1600 | 1020 | 150-300 | 220 | 520-1275 | 250 | 5800×3700×4280 | 83.3 |

| LTC200 | 1500×2000 | 1200 | 175-300 | 200 | 760-1590 | 400 | 6700×4040×4466 | 137.16 |

Capacity parameter table

| Product size (mm) |

Closed Sied Setting(mm) |

FTC 800 | FTC 1000 | FTC 960 | FTC 1060 | FTC 1160 | FTC 1100 | FTC 1200 | FTG 1250 | FTC 1400 | FTC 1600 | FTC 2000 |

| Mtph(t/h) | ||||||||||||

| 0-60 | 40 | 55-75 | ||||||||||

| 0-75 | 50 | 60-90 | ||||||||||

| 0-90 | 60 | 75-95 | 105-130 | |||||||||

| 0-105 | 70 | 95-130 | 120-170 | 120-150 | 155-185 | 160-205 | 165-220 | 175-235 | ||||

| 0-120 | 80 | 105-155 | 140-205 | 145-175 | 160-210 | 180-230 | 175-250 | 195-275 | ||||

| 0-135 | 90 | 120-170 | 155-215 | 155-200 | 195-235 | 200-255 | 195-275 | 205-300 | ||||

| 0-150 | 100 | 145-185 | 175-255 | 170-220 | 205-260 | 225-280 | 210-290 | 2230-325 | 240-335 | |||

| 0-185 | 125 | 170-240 | 215-305 | 225-280 | 250-320 | 275-340 | 260-366 | 280-395 | 300-405 | 325-450 | ||

| 0-225 | 150 | 215-285 | 270-360 | 260-330 | 305-380 | 315-410 | 315-425 | 345-480 | 345-480 | 375-530 | 435-610 | |

| 0-260 | 175 | 240-330 | 315-430 | 310-385 | 360-455 | 375-465 | 355-495 | 385-545 | 395-540 | 440-605 | 495-690 | 630-895 |

| 0-300 | 200 | 350-485 | 390-505 | 410-525 | 405-550 | 440-615 | 490-685 | 565-795 | 715-1000 | |||

| 0-340 | 225 | 490-680 | 550-765 | 625-885 | 785-1105 | |||||||

| 0-375 | 250 | 550-750 | 615-845 | 680-965 | 865-1210 | |||||||

| 0-410 | 275 | 740-1015 | 945-1320 | |||||||||

| 0-450 | 300 | 815-1150 | 1051-1440 | |||||||||

PE鄂式破碎机.png)

冲击式破碎机1.png)

复摆型鄂式破碎机2.png)

复摆型鄂式破碎机1.png)