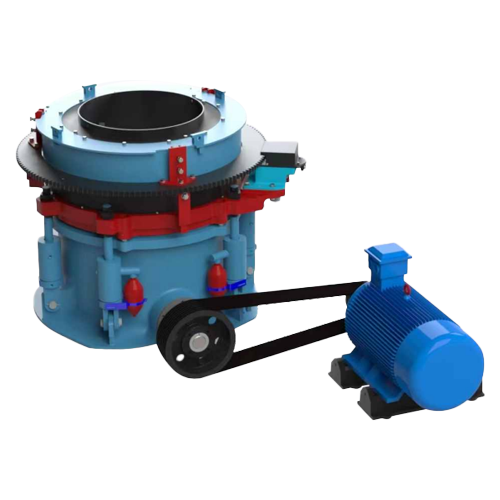

Shenyang Fente FTP series multiple cylinder hydraulic cone crushers are the pacemaker in China's multiple cylinder hydraulic cone crushers for the excellent operating performance and positive customer feedback.

It incorporates the latest global crushing technologies with high efficiency and easy operation. Moreover, the FTP series multiple cylinder hydraulic cone crushers can efficiently fulfill all your crushing demands, such as: large capacities, first-class cubicity, high percentage of fine and products, low operating and maintenance cost, full process adaptability etc.

FTP series multiple cylinder hydraulic cone crushers are widely applied in metal ore and non-metal ore secondary, tertiary and quaternary crushing application in different industries such as mining, cement, sand, stone, metallurgical etc. Especially they are well suited to perform well in tertiary and quaternary crushing process.

Working principle

The moving cone of the cone crusher, driven by the eccentric sleeve, performs a gyratory and swing motion, which in turn drives the crushing wall to exert pressure and grinding on the material between it and the concave wall. According to the lamination theory, the material is subjected to forces from multiple directions, causing it to break and be polished along its natural grain, ultimately forming stable stone particles. The particles that meet the discharge requirements fall through the gaps created by the gyratory and swing motion of the crushing wall, while the remaining material continues to be crushed until it meets the final requirements.

Specifications

| Model | Cavity | Maximum feeding size(mm) | Minimum Discharging size(mm) |

Capacities (t/h) |

Maximum Installed power(kw) |

| FTP100 | Extra Coarse | 140 | 19 | 75-140 | 90 |

| Coarse | 100 | 13 | 60-110 | ||

| Medium | 70 | 9 | 52-100 | ||

| Fine | 50 | 9 | 50-95 | ||

| Extra Fine | 20 | 6 | 45-90 | ||

| FTP200 | Coarse | 185 | 19 | 145-250 | 160 |

| Medium | 125 | 16 | 135-235 | ||

| Fine | 95 | 13 | 115-220 | ||

| Extra Fine | 75 | 10 | 90-190 | ||

| FTP300 | Extra Coarse | 230 | 25 | 220-440 | 250 |

| Coarse | 210 | 19 | 190-380 | ||

| Medium | 150 | 16 | 175-320 | ||

| Fine | 105 | 13 | 145-280 | ||

| Extra Fine | 80 | 10 | 110-240 | ||

| FTP400 | Extra Coarse | 295 | 30 | 300-630 | 315 |

| Coarse | 251 | 25 | 285-560 | ||

| Medium | 196 | 20 | 250-490 | ||

| Fine | 110 | 13 | 180-345 | ||

| Extra Fine | 90 | 10 | 135-320 | ||

| FTP500 | Extra Coarse | 330 | 38 | 425-790 | 400 |

| Coarse | 290 | 30 | 370-700 | ||

| Medium | 210 | 22 | 330-605 | ||

| Fine | 135 | 16 | 270-535 | ||

| Extra Fine | 95 | 13 | 220-430 | ||

| FTP800 | Extra Coarse | 350 | 38 | 570-1200 | 630 |

| Coarse | 299 | 32 | 520-1050 | ||

| Medium | 265 | 25 | 475-950 | ||

| Fine | 220 | 16 | 370-800 | ||

| Extra Fine | 150 | 13 | 310-600 |

Notes:

Capability in table is on the basis of middle hard material with stack density of 1. 6t/m³.

Crushing machine is an important component of product line. It's performance also needs other machine's cooperation, like feeder, transportation belt, vibrating screen and supporting etc. According to the requirement of layer pressure crushing theory, the machine will achieve theory, the machine will achieve excellent performance when fed sufficiently.

Throughput:

| Discharge Opening Size | 6mm | 8mm | 10mm | 13mm | 16mm | 19mm | 22mm | 25mm | 32mm | 38mm | 45mm | 51mm |

| FTP100 | 45-55 | 50-60 | 55-70 | 60-80 | 70-90 | 75-95 | 80-100 | 90-115 | 100-150 | |||

| FTP200 | 65-85 | 90-125 | 110-115 | 135-180 | 160-210 | 170-225 | 190-235 | 210-250 | ||||

| FTP300 | 85-120 | 180-220 | 200-240 | 220-260 | 235-290 | 250-320 | 300-380 | 350-440 | ||||

| FTP400 | 135-180 | 190-230 | 225-275 | 250-320 | 270-350 | 295-380 | 290-375 | 355-490 | 410-565 | 460-625 | ||

| FTP500 | 200-250 | 230-290 | 280-350 | 320-400 | 345-430 | 510-700 | 580-790 | |||||

| FTP800 | 265-340 | 320-425 | 385-510 | 425-540 | 470-605 | 495-740 | 545-800 | 600-945 | 690-1050 | 785-1200 |

The production capacity can be used as a tool for the preliminary selection of FTP cone crusher, The data in the table is based on the measurement results of instantaneous sampling with the loose density of 1.6/m³; The content of fine particles in the feed is relatively high, and the capacity of the equipment under closed circuit operation is about 15% - 30% higher than that under open circuit operation.

Performance advantages

- Fixed spindle, with strong bearing capacity, more compact structure, small size and high efficiency.

- The crushing efficiency and the proportion of fine materials are significantly improved by using the principle of inter particle laminated design and the mutual extrusion between materials, which greatly reduces the needle shaped materials and the steel consumption of vulnerable parts.

- Advanced bearing design adopts tin bronze bushing sliding bearing design, Compared with rolling bearing, the equipment can still maintain ultra-high load capacity under high dust and high impact environment, and the production cost is low.

- Install a temperature sensor at the oil return point of the horizontal shaft to accurately detect the oil temperature to ensure the stable operation of the equipment. The transmission system adopts spiral bevel gear, which is reliable and stable with low noise and long service life.

- While the cone wall is thickened, the lining plate fixing method is improved, without the need for glue pouring, which is very convenient and quick to replace, and reduces the maintenance cost.

- Integrated hydraulic lubrication and unique thin oil lubrication system design greatly improve the service life of the equipment. High performance non-contact labyrinth seals are more conducive to ensuring the cleanliness of lubricating oil.

- The oil circuit of the safety cylinder adopts a large diameter oil pipe and a large capacity accumulator, which has better cushioning performance, faster response and safer equipment.

多缸液压圆锥破碎机.png)

多缸液压圆锥破碎机多缸圆锥破4.png)

多缸液压圆锥破碎机多缸圆锥破1.png)