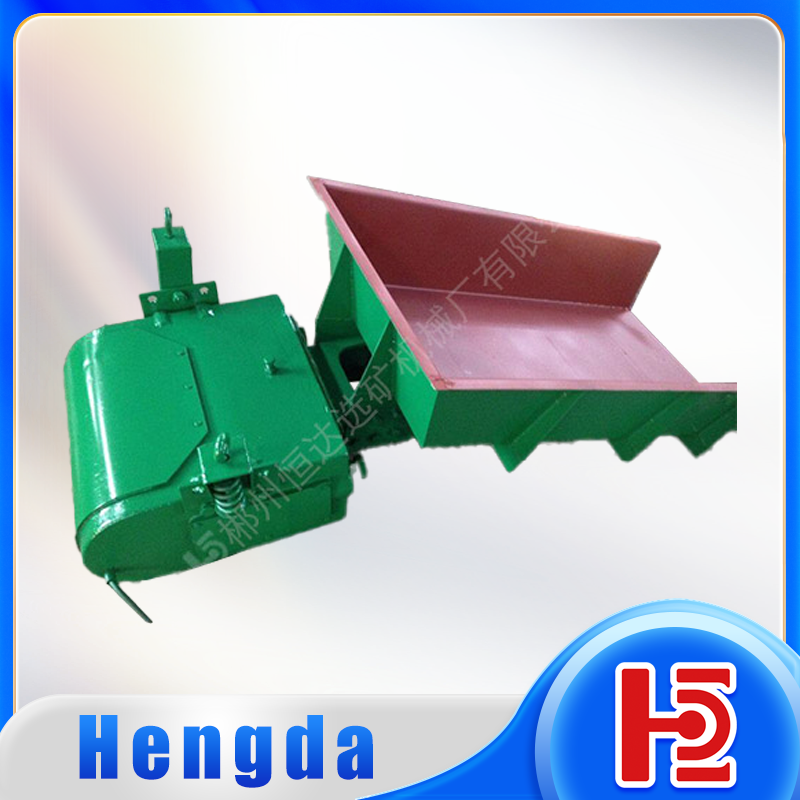

FT vibrating feeder adopts grid structure, which can coarse screen materials. Reduce equipment loss, improve production efficiency of crushing equipment, and make equipment configuration more optimized, more economical and reasonable. In the production process, the feeder sends the massive and granular rocks into the receiving equipment evenly, regularly and continuously to prevent the receiving equipment from jamming and crashing due to uneven feeding. Ensure continuous and efficient production of equipment. At present, the bar vibrating feeder has been widely used in the crushing and screening fields of metallurgy, mineral processing building materials, sand and gravel industries, and has become an essential equipment for crushing production lines.

Performance benefits

- Synchronous vibration, eccentric shaft oil immersion lubrication,

- The weight and impact angle of the eccentric block are adjustable, and the amplitude can be adjusted by increasing or decreasing the counterweight,

- The spacing between bars can be adjusted within the range of 40-200mm to fully pre screen the materials,

- The tank and bearing are designed according to heavy working conditions, with strong impact resistance.stable vibration, large processing capacity, reliable operation and long service life.

Specifications and performance parameters

| Model | Size of Funnel(mm) | Max.Feed Size(mm) | Capacity(t/h) | Power(kw) | Overall Dimension(mm) |

| FTZ850×3000 | 850×3000 | 400 | 40-100 | 2X22 | 3050×1430×1550 |

| FTZ960×3800 | 960×3800 | 500 | 90-200 | 15 | 3880×2240×1880 |

| FTZ1100×4200 | 1100×4200 | 580 | 150-350 | 15 | 4300×2450×2010 |

| FTZ1100×4900 | 1100×4900 | 580 | 180-380 | 15 | 4980×2450×2010 |

| FTZ1300×4900 | 1300×4900 | 750 | 250-450 | 22 | 4980×2710×2050 |

| FTZ1500×6000 | 1500×6000 | 800 | 600-1000 | 30 | 6160×2919×2293 |