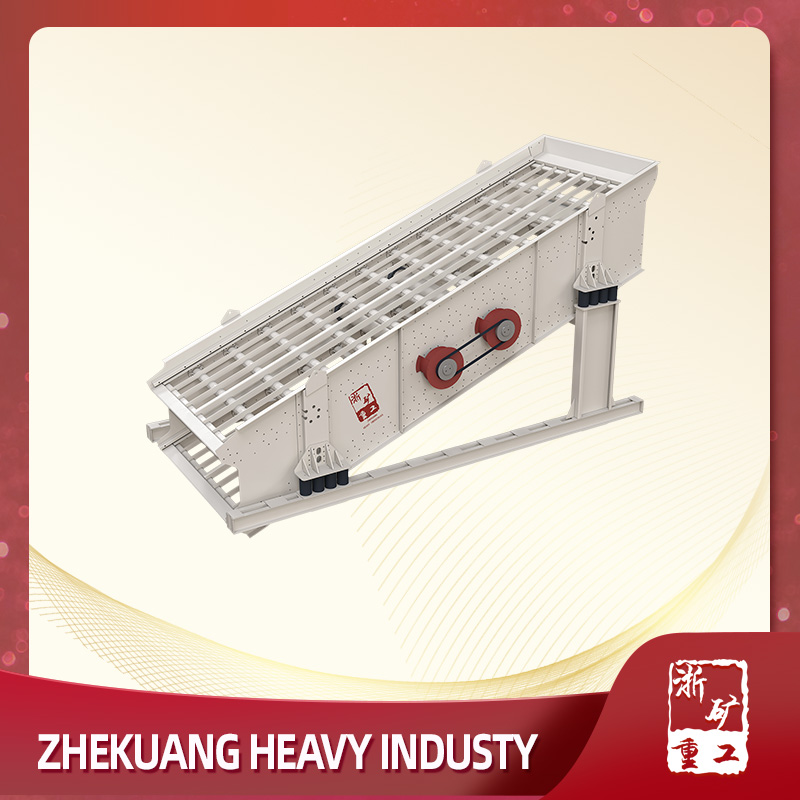

In view of the single function of the existing vibrating screen, FTES series three-axis elliptical screen was born according to the potential. The utility model solves the design defects of high center of gravity of the circular motion screen, large floor space, small processing capacity of the linear motion screen, and easy hole plugging. FTES series of sieving machines can not only adapt to the screening of various materials, but also can classify, dehydrate, demineralize and desilter the materials that are difficult to screen.

Screening advantages

1. The three-axis drive can make the screen machine produce ideal elliptical motion. it has the advantages of both circular and linear vibrating screens, and the amplitude of the elliptical trajectory is adjustable. The vibration trajectory can be selected according to the actual material conditions,which is more advantageous for materials that are difficult to screen.

2. The three-axis drive forced synchronous excitation can make the screen machine obtain a stable working stale. It is especially beneficial for screening with large processing capacity, The three-axis drive improves the stress state of the screen frame, reduces the load of a single bearing, and the force on the side plate is uniform. it reduces the stress concentration point,improves the stress condition of the screen frame, and improves the reliability and life of the screen machine,laying a theoretical foundation for the large-scale screen machine.

3. Due to its horizontal installation, the unit height is effectively reduced, which can well meet the needs of large and medium-sized mobile screening units. The thin oil lubrication of the bearing effectively reduces the bearing temperature, improves the screening area with the same service life, and the output of the elliptical vibrating screen can be increased by 2-3 times.

Specifications and performance parameter

| Model | Specification W×L(mm) | Screening Area (m²) | Number of Layers | Max.Feed Size (mm) |

Stroke (mm) |

Frequency (r/min) | Capacity (t/h) |

Power (kw) |

Weight (t) |

| 2ES1852 | 1.8×5.2 | 9.45 | 2 | 150 | 14-18 | 645-875 | 150-300 | 22 | - |

| 3ES1852 | 1.8×52 | 9.45 | 3 | 14-18 | 150-300 | 30 | - | ||

| 2ES1860 | 1.8×6.0 | 10.08 | 2 | 14-18 | 200-400 | 37 | - | ||

| 3ES1860 | 1.8×6.0 | 10.08 | 3 | 14-18 | 200-400 | 37 | - | ||

| 2ES2060 | 2.0×6.0 | 12 | 2 | 14-18 | 400-600 | 37 | - | ||

| 4ES2060 | 2.0×6.0 | 12 | 4 | 14-18 | 400-600 | 45 | - | ||

| 3ES2460 | 2.4×6.0 | 14.4 | 3 | 14-18 | 600-900 | 45 | - | ||

| 4ES2460 | 2.4×6.0 | 14.4 | 4 | 14-18 | 600-900 | 45 | - |

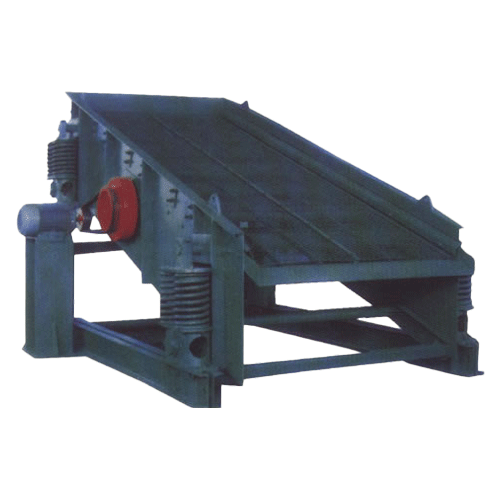

圆振动筛.png)