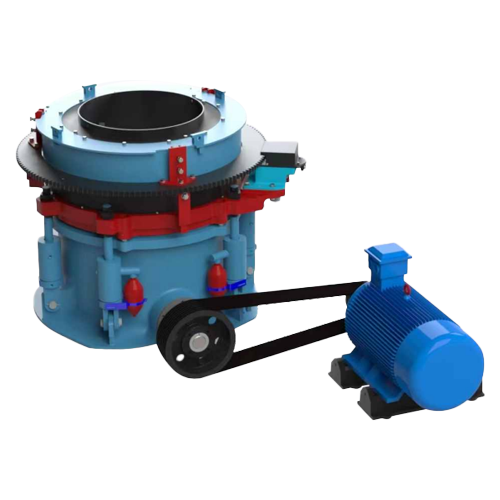

Widely used for secondary and tertiary crushing in mining and aggregate industries, its heavy-duty design enables superior stability. The optimized main unit structure, combined with a large eccentric distance and high rotational speed, significantly enhances production capacity and crushing efficiency. The "Lamination crushing principle ensures superior product shape.

PERFORMANCE FEATURE

- Heavy-Duty Design

The main shell structure is optimized with a high-quality alloy steel forged main shaft, and finite element analysis is conducted to enhance the reliability of the equipment under heavy-duty conditions.

- Efficient Overload Protection

Hydraulic cylinders and accumulators are installed around the main unit.allowing uncrushable materials to pass quickly through the crushing cavity, reducing downtime and minimizing damage to the crusher.

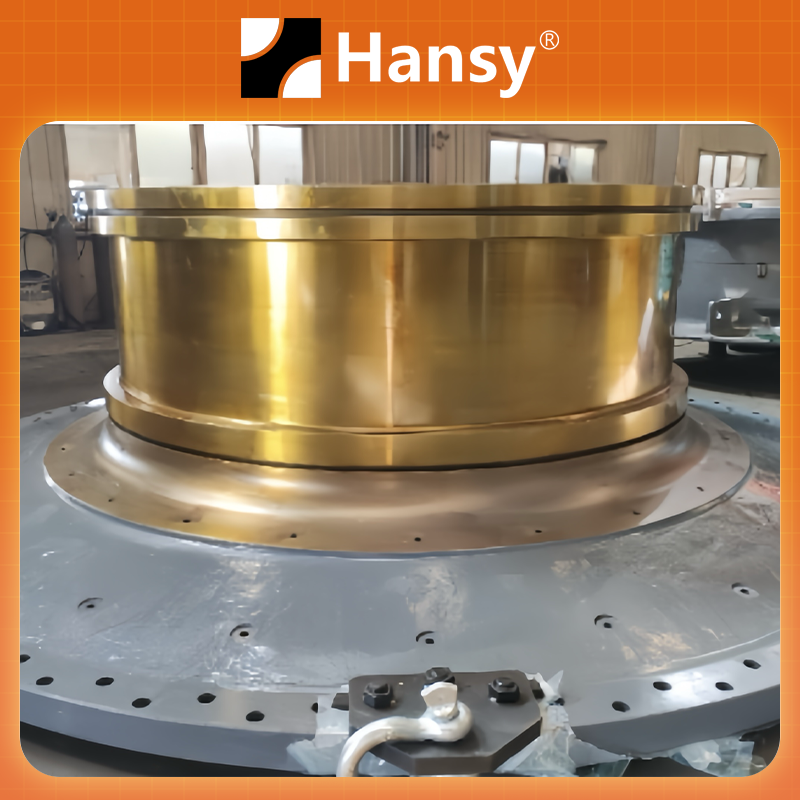

- Convenient C.S.S.Adjustment Device

The hydraulic motor drives the bowl's rotation for precise adjustment of the closed side setting, while also allowing the bowl to rotate completely out of the adjustment ring threads for the ease of liner replacement.

- Reliable Dust Prevention Design

Utilizing "U" and "T" labyrinth seals along with a positive pressure fan ensures effective dust prevention.

- Flexible Cavity Adjustment

By replacing the liners, torque rings, and fastening bolts, the crushing cavity can be switched from standard coarse to short-headed fine configurations.

- Comprehensive Wear Protection

All critical components of the crusher are equipped with wear protection.significantly reducing maintenance costs.

MAIN TECHNICAL SPECIFICATION

| Model | Max. Feed Size(mm) | C.S.S.(mm) | Motor Power(kw) | Capacity(t/h) | Weight(t) |

| MH100 | 140 | 6-32 | 90 | 50-150 | 6.5 |

| MH200 | 170 | 6-38 | 160 | 65-260 | 12.5 |

| MH300 | 240 | 8-45 | 250 | 90-450 | 18.6 |

| MH400 | 300 | 8-51 | 315 | 110-645 | 26 |

| MH500 | 310 | 8-55 | 400 | 135-800 | 37.6 |

| MH600 | 330 | 10-55 | 500 | 225-800 | 45.5 |

| MH800 | 350 | 10-60 | 630 | 265-1220 | 66.4 |

| MH1000 | 340 | 8-60 | 710 | 370-1950 | 125 |

| MH1100 | 360 | 9-75 | 800 | 500-2450 | 160 |

| MH1300 | 370 | 10-75 | 1000 | 590-3025 | 178 |

多缸液压圆锥破碎机.png)

多缸液压圆锥破碎机.png)

多缸液压圆锥破碎机多缸圆锥破4.png)

多缸液压圆锥破碎机多缸圆锥破1.png)