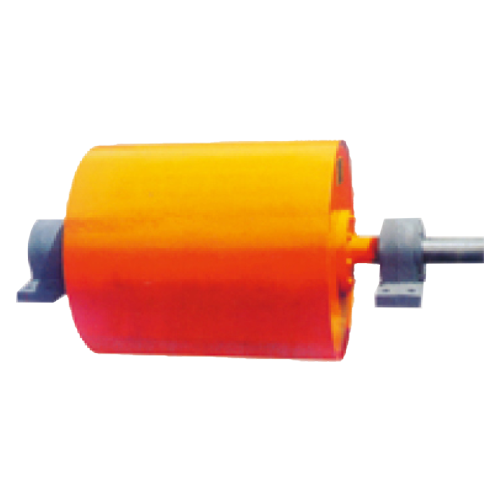

T-QCG series dry roller strong magnetic separator is a newly developed strong magnetic dry separation equipment by our company, used for the separation of weakly magnetic minerals such as hematite, specularite, limonite, manganese ore, new iron spinel, pseudo semi pseudo magnetite, siderite, chromite, tungsten ore, tantalum niobium ore, etc.

In the non-metallic mineral industry, such as various refractory materials, andalusite, kyanite, sillimanite, zircon, quartz sand, feldspar, ceramic raw materials and other non-metallic minerals, it is necessary to remove the iron contained inside and use strong magnetic separation to dry select and purify non-metallic minerals, which is a very effective method. T-QCG series dry permanent magnet roller type strong magnetic separator is used to separate weakly magnetic minerals and remove iron from non-metallic ores. It has the characteristics of simple equipment configuration, high processing capacity per unit weight, good sorting effect, and low production cost. The machine adopts a configuration of an upper magnetic roller and a lower magnetic roller. The material first passes through the upper magnetic roller of the medium magnet to select strong magnetic minerals, and then enters the strong magnetic roller below for sorting. The lower magnetic roller uses high-performance permanent magnet materials as the magnetic source, with a working field strength of over 1.4 Tesla. It has high magnetic field strength, large magnetic field gradient, and strong magnetic attraction to weakly magnetic minerals, which can effectively sort and adsorb weakly magnetic minerals;

The specifications of T-QCG series dry permanent magnet roller strong magnetic separator have been serialized, and its rolling diameter, roller factory, and number of rollers can be selected according to different materials and user needs.

Specification, model, and main technical performance parameters of T-QCG series dry permanent magnet roller type strong magnetic separator

|

Parameter Model |

Roll diameter(mm) |

Roll length(mm) |

Magnetic induction intensity of cylinder meter(T) |

Processing capacity(t/h) |

Applicable bandwidth(mm) |

Feeding grain size(mm) |

Single roll drive power(kW) |

Overall weight(kg) |

|

T-QCG3507 |

350 |

750 |

0.5-1.5 |

10-18 |

650 |

15-0 |

1.5 |

2000 |

|

T-QCG3510 |

350 |

1080 |

20-35 |

1000 |

15-0 |

1.5 |

2500 |

|

|

T-QCG3512 |

350 |

1230 |

30-40 |

1150 |

15-0 |

1.5 |

2900 |

|

|

T-QCG0506 |

500 |

600 |

8-15 |

500 |

15-0 |

2.2 |

2800 |

T-QCG型干式永磁辊式强磁选机.png)

TD系列永磁笼式尾矿回收机.png)

高效细粉筛.png)

PC系列永磁盘式尾矿磁选机.png)

NCT系列浓缩磁选机.png)

CTDG系列永磁干式大块磁选机.png)

T-GCT系列高效永磁湿式磁选机.png)