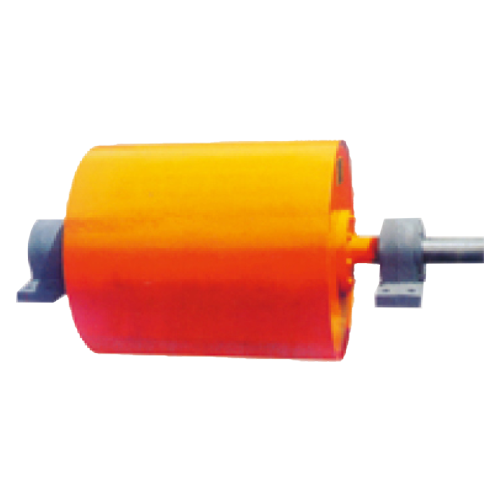

NCT series concentrated magnetic separator is a newly developed magnetic separator specifically designed for adjusting the concentration of magnetic minerals in the up and down operation sections of magnetic separation plants. This product has obtained a national patent, patent number: ZL200720046470.7. The characteristics are high recovery rate for strong magnetic minerals, large processing capacity, and significant concentration effect. When the mineral concentration is 20% -25%, the recovery rate of magnetic iron can reach over 99.5%, and the concentration can reach 50% -70%. It can completely replace traditional large dewatering tanks and concentration tanks in the concentration of strong magnetic minerals.

The magnetic system structure of this equipment has been optimized and designed, with a larger magnetic wrap angle and more reasonable magnetic force distribution. This allows smaller cylinders to have a larger sorting space to accommodate a large amount of magnetic concentrate passing through, minimizing the loss of useful minerals. This machine adopts a non-magnetic scraper for ore unloading, supplemented by a concentrate flushing water pipe to adjust the water volume and ensure that the concentrate has an appropriate concentration.

Magnetic separation plants with significant changes in feed slurry concentration can also be adjusted to a more stable concentration and higher recovery rate.

Technical parameter

|

Parameter Moedl |

Specifications | Rotate speed(r/min) |

Magnetic induction intensity of cylinder meter(mT) |

Processing capacity |

Motor power(kW) |

Reducer |

Overall weight(kg)

|

||

|

Cylinder diameter(mm) |

Cylinder length(mm) |

Dry ore(T/h) |

Ore pulp(m³/h)

|

||||||

|

NCT0715 |

750 |

1500 |

35 |

According to user requirements and specific mineral properties to determine |

25-30 |

80-120 |

2.2 |

BWD13-43-2.2 |

2100 |

|

NCT0718 |

750 |

1800 |

35 |

30-50 |

120-160 |

3 |

BWD13-43-3 |

2500 |

|

|

NCT0918 |

900 |

1800 |

25 |

35-50 |

140-200 |

4 |

BWD14-59-4 |

3100 |

|

|

NCT0921 |

900 |

2100 |

25 |

40-60 |

160-210 |

4 |

BWD14-59-4 |

3400 |

|

|

NCT1015 |

1050 |

1500 |

20 |

35-50 |

140-200 |

4 |

JZQ350-48.57 |

3660 |

|

|

NCT1018 |

1050 |

1800 |

20 |

40-60 |

160-210 |

4 |

4150 |

||

|

NCT1021 |

1050 |

2100 |

20 |

60-80 |

180-240 |

4 |

4560 |

||

|

NCT1024 |

1050 |

2400 |

20 |

70-90 |

200-270 |

5.5 |

JZQ400-48.57 |

5050 |

|

|

NCT1030 |

1050 |

3000 |

20 |

80-100 |

260-340 |

7.5 |

ZSY180-50 |

6550 |

|

|

NCT1224 |

1200 |

2400 |

17 |

70-95 |

210-280 |

7.5 |

ZSY180-56 |

5500 |

|

|

NCT1226 |

1200 |

2600 |

17 |

75-100 |

230-300 |

7.5 |

6000 |

||

|

NCT1230 |

1200 |

3000 |

17 |

90-130 |

260-350 |

11 |

6800 |

||

|

NCT1232 |

1200 |

3200 |

17 |

95-140 |

280-370 |

15 |

ZSY200-31.5 |

7600 |

|

|

NCT1236 |

1200 |

3600 |

17 |

100-160 |

300-390 |

15 |

8200 |

||

|

NCT1240 |

1200 |

4000 |

17 |

120-180 |

330-430 |

15 |

8800 |

||

|

NCT1245 |

1200 |

4500 |

17 |

135-210 |

370-500 |

15 |

9550 |

||

|

NCT1530 |

1500 |

3000 |

13.6 |

|

130-180 |

250-380 |

15 |

ZSY200-40 |

9800 |

|

NCT1540 |

1500 |

4000 |

13.6 |

150-220 |

350-450 |

18.5 |

ZSY224-40 |

11000 |

|

|

NCT1545 |

1500 |

4500 |

13.6 |

180-250 |

380-500 |

18.5 |

12600 |

||

|

NCT1560 |

1500 |

6000 |

13.6 |

250-300 |

600-750 |

30 |

ZSY250-40 |

15300 |

|

NCT系列浓缩磁选机.png)

TD系列永磁笼式尾矿回收机.png)

高效细粉筛.png)

T-QCG型干式永磁辊式强磁选机.png)

PC系列永磁盘式尾矿磁选机.png)

CTDG系列永磁干式大块磁选机.png)

T-GCT系列高效永磁湿式磁选机.png)