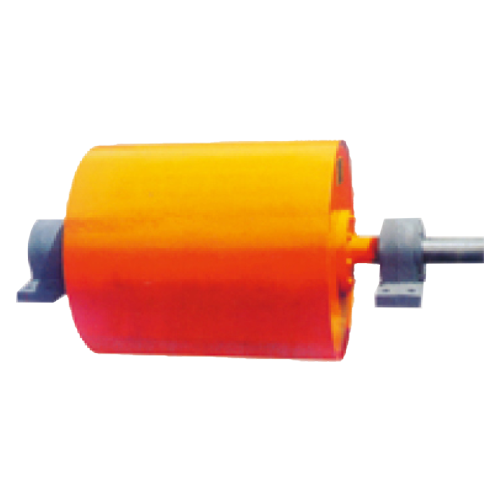

CTDG series permanent magnet dry bulk magnetic separator is an efficient dry beneficiation equipment widely used in black metal mines and beneficiation plants. This series of equipment has a mature structure, high magnetic field strength, light weight, reliable operation, and convenient maintenance, making a significant contribution to the economic benefits of mines. In addition to the current standardized products, dry magnetic separators (magnetic pulleys) with different magnetic induction strengths and suitable for various belt specifications can also be made according to user needs. Our company has developed and produced the world's largest dry separation machine, which has been running steadily for many years at Shougang Mining Company. This product is mainly used in the following situations:

1. The pre selection operation of the magnetic separation plant can remove the waste rock mixed into the ore, restore the geological grade, save energy, improve the processing capacity of the beneficiation plant, and extend the service life of the tailings pond.

2. Used for dumping sites to recover iron ore from waste rock and improve the utilization rate of ore resources.

3. Used for processing waste steel slag in steel plants and recovering metallic iron.

4. Useful metals for garbage disposal and sorting, improving the environment.

Specifications, models, and main technical performance parameters of CTDG series bulk dry magnetic separators

|

Parameter Model |

Specifications |

Belt speed (m/s) |

Magnetic induction intensity of cylinder meter(mT) |

Processing capacity |

A |

Applicable bandwidth B |

||

|

Cylinder diameter(D) |

Cylinder length(L) |

Dry ore volume(t/h) |

Processing grain size(mm) |

|||||

|

mm |

mm |

mm |

mm |

|||||

|

CTDGO505 |

500 |

600 |

1.6 |

According to user requirements and specific mineral properties to determine |

30-50 |

0-70 |

850 |

500 |

|

CTDG0606 |

630 |

750 |

1.6 |

55-65 |

0-70 |

1000 |

650 |

|

|

CTDGO608 |

630 |

950 |

1.6 |

75-100 |

0-70 |

1300 |

800 |

|

|

CTDG0810 |

800 |

1150 |

1.6 |

120-150 |

0-150 |

1500 |

1000 |

|

|

CTDG0812 |

800 |

1400 |

1.6 |

160-200 |

0-150 |

1750 |

1200 |

|

|

CTDG1008 |

1000 |

950 |

1.8 |

180-220 |

0-200 |

1300 |

800 |

|

|

CTDG1010 |

1000 |

1150 |

1.8 |

200-250 |

0-200 |

1500 |

1000 |

|

|

CTDG1012 |

1000 |

1400 |

1.8 |

280-350 |

0-200 |

1750 |

1200 |

|

|

CTDG1014 |

1000 |

1600 |

1.8 |

380-450 |

0-200 |

2000 |

1400 |

|

|

CTDG1212 |

1250 |

1400 |

2 |

350-400 |

0-400 |

1750 |

1200 |

|

|

CTDG1214 |

1250 |

1600 |

2 |

380-450 |

0-400 |

2000 |

1400 |

|

|

CTDG1216 |

1250 |

1800 |

2 |

500-550 |

0-400 |

2300 |

1600 |

|

|

CTDG1414 |

1400 |

1600 |

2.2 |

450-500 |

0-500 |

2000 |

1400 |

|

|

CTDG1420 |

1400 |

2200 |

2.2 |

900-1200 |

0-500 |

2600 |

2000 |

|

|

CTDG1516 |

1500 |

1800 |

2.5 |

600-700 |

0-650 |

2300 |

1600 |

|

|

CTDG1527 |

1500 |

2700 |

2.5 |

1000-1200 |

0-650 |

3100 |

2400 |

|

CTDG系列永磁干式大块磁选机.png)

TD系列永磁笼式尾矿回收机.png)

高效细粉筛.png)

T-QCG型干式永磁辊式强磁选机.png)

PC系列永磁盘式尾矿磁选机.png)

NCT系列浓缩磁选机.png)

T-GCT系列高效永磁湿式磁选机.png)