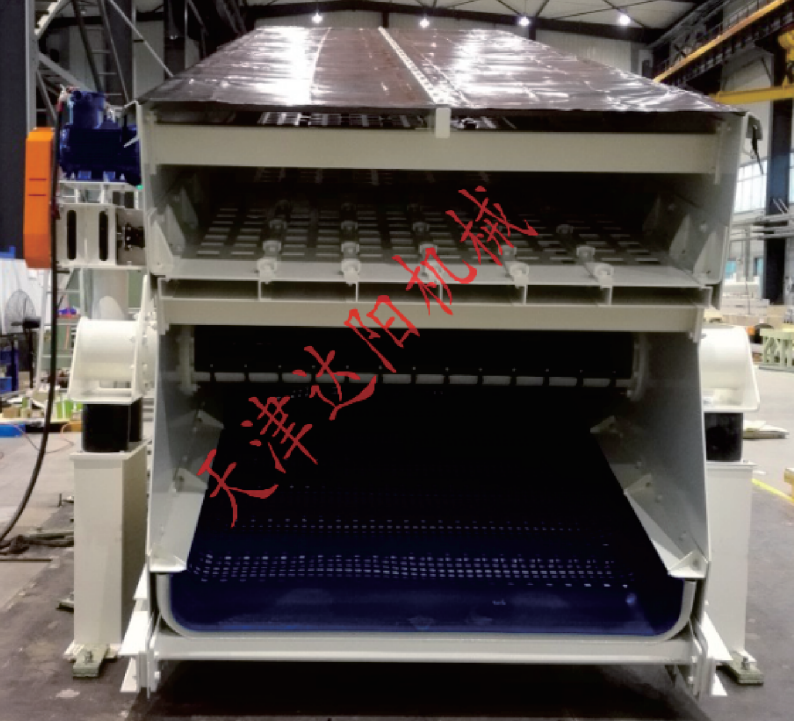

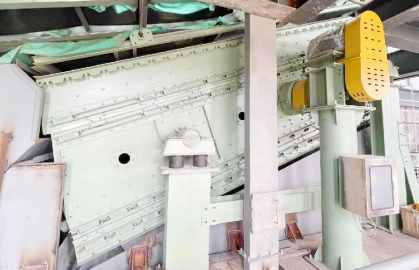

GXFS series high efficiency fine powder sieve is a dry and efficient screening equipment developed by Tiangong Technology Co., Ltd. in recent years. It is particularly suitable for difficult to screen materials such as fine, wet, and sticky materials. It is usually used in metal mine selection plants for screening materials after high-pressure roller grinding or fine crushing. In the building materials and sand and gravel industries, it is used for screening crushed materials, and the screening efficiency is increased by more than 15% compared to ordinary circular vibrating screens.

GXFS series high efficiency fine powder sieve of Tiangong Technology has the characteristics of high screening efficiency, low power consumption, small workload for cleaning the screen surface, and easy maintenance, which can achieve continuous and stable industrial production. At present, high-efficiency fine powder screening has been widely applied in many domestic industries such as iron ore, limestone mines, sand and gravel yards, garbage treatment, and coal mines, achieving significant economic benefits on site.

The main characteristics of GXFS series high efficiency fine powder sieve are: the superposition of main and auxiliary vibrations causes severe shaking of the elastic sieve surface, resulting in a rebound acceleration of 30-50g of the material on the sieve plate, greatly enhancing the activity of the material. It is not easy to stick to the sieve and block holes, and the material is fully loose and permeable through the sieve, completing the screening and grading process.

GXFS series high-efficiency fine powder sieve is a dry and efficient screening equipment developed by Tiangong Technology Co., Ltd. in recent years. It is particularly suitable for difficult to screen materials such as fine, wet, and sticky materials. It is usually used in metal mine selection plants for screening materials after high-pressure roller grinding or fine crushing. In the building materials and sand and gravel industries, it is used for screening crushed materials, and the screening efficiency is increased by more than 15% compared to ordinary circular vibrating screens.

The GXFS series high-efficiency fine powder sieve of Tiangong Technology has the characteristics of high screening efficiency, low power consumption, small workload for cleaning the screen surface, and easy maintenance, which can achieve continuous and stable industrial production. At present, high-efficiency fine powder screening has been widely applied in many domestic industries such as iron ore, limestone mines, sand and gravel yards, garbage treatment, and coal mines, achieving significant economic benefits on site.

The main characteristics of GXFS series high-efficiency fine powder sieve are: the superposition of main and auxiliary vibrations causes severe shaking of the elastic sieve surface, resulting in a rebound acceleration of 30-50g of the material on the sieve plate, greatly enhancing the activity of the material. It is not easy to stick to the sieve and block holes, and the material is fully loose and permeable through the sieve, completing the screening and grading process.

Technical parameter

1. Amplitude: Circular amplitude 4-7.5 mm Linear amplitude 12-18 mm

2. Material acceleration: 30g-50g

3. Feeding particle size: 0-80 mm

4. Grading particle size: 1-8 mm

At present, the screening area of the large-scale GXFS high-efficiency fine powder sieve designed and manufactured by Tiangong Technology Co., Ltd. can reach 50 square meters, and the single machine processing capacity can reach over 500t/h, fully meeting the needs of enterprises for large-scale equipment and achieving the goal of energy conservation and emission reduction.

Specification, model, technical performance

|

No. |

Model |

Sieve surface width(mm) |

Sieve surface length(mm) |

Sieving area(㎡) |

1mm processing capacity(t/h) |

5mm processing capacith(t/h) |

|

Single layer sieve (A)(Loose bulk density 2.0, the surface moisture of the material is lower than 6%)

|

GXFS1861A |

1800 |

6100 |

10.98 |

105 |

200 |

|

GXFS2461A |

2400 |

6100 |

14.64 |

140 |

270 |

|

|

GXFS3061A |

3000 |

6100 |

18.3 |

180 |

320 |

|

|

GXFS3675A |

3600 |

7500 |

27 |

220 |

420 |

|

|

GXFS43120A |

4300 |

12000 |

43 |

300 |

500 |

|

|

No. |

Model |

Sieve surface Width(mm) |

Sieve surface length(mm) |

Sieving area(㎡) |

1mm processing capacity(t/h) |

5mm processing capacity(t/h) |

|

Double layer sieve (B)(Loose bulk density 2.0, the surface moisture of the material is lower than6%, the upper layer removes 50% Quantity of material)

|

GXFS1861B |

1800 |

6100 |

21.96 |

140 |

280 |

|

GXFS2461B |

2400 |

6100 |

29.28 |

190 |

380 |

|

|

GXFS3061B |

3000 |

6100 |

36.6 |

320 |

600 |

|

|

GXFS3675B |

3600 |

7500 |

54 |

380 |

800 |

|

|

GXFS43120B |

4300 |

12000 |

86 |

500 |

1200 |

高效细粉筛.png)

TD系列永磁笼式尾矿回收机.png)

T-QCG型干式永磁辊式强磁选机.png)

PC系列永磁盘式尾矿磁选机.png)

NCT系列浓缩磁选机.png)

CTDG系列永磁干式大块磁选机.png)

T-GCT系列高效永磁湿式磁选机.png)

DCZ弛张筛系列产品_副本.png)