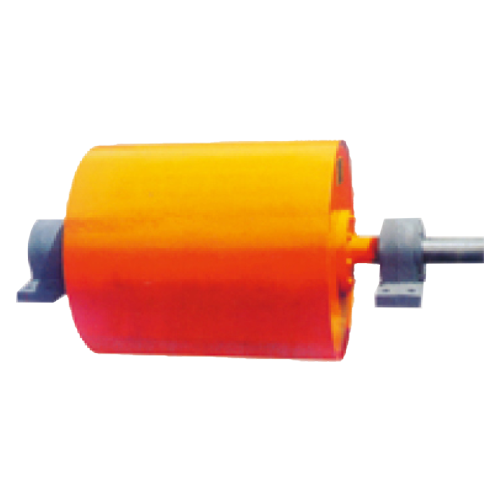

T-GCT series high-efficiency permanent magnet wet magnetic separator was developed by our company in 2004. This series of equipment is based on the latest "double high" design concept, abandoning the shortcomings of traditional cylindrical magnetic separators in design and manufacturing. It adopts the most reasonable design and manufacturing technology today, combined with the use of high-performance magnetic materials, to break through the traditional magnetic circuit distribution structure of magnetic separators. It forms a magnetic field performance with gradient, smoothness, and high magnetic stirring factor, and designs a multi-functional tank that matches it. In a reasonable process, it can break through the traditional magnetic separation concept, while obtaining high grade and high recovery rate. This series of products was supported by the Innovation Fund of the Ministry of Science and Technology of China in 2010, and in 2012, it was also supported by the Innovation Fund of the Ministry of Science and Technology of China. Passed the expert rental review and acceptance in May of this year.

The new model has been applied in the magnetic separation process of many beneficiation plants nationwide and has been widely recognized by users. According to user needs, this model can be equipped with semi counter current, counter current, and co current tank bodies. It is suitable for all traditional drum magnetic separators and has significantly better sorting performance than traditional drum magnetic separators. It can be used in double tube, three tube, and four tube configurations, and the magnetic induction strength can be specially designed according to the on-site mineral properties and process requirements. The equipment has advanced structure, reasonable magnetic structure, reliable operation, and convenient maintenance. It has now formed a series of products that can meet the needs of large, medium, and small mining plants.

T-GCTφ1500, φ1200, φ1050, φ900, φ750 series of high efficiency permanent magnet wet magnetic separator specifications and main technical performance parameters

|

Parameter Model |

Specifications |

Rotate speed(r/min) |

Magnetic induction intensity of cylinder meter(mT) |

Processing capacity |

Motor power(KW)

|

Reducer |

Overall weight(kg) |

||

|

Cylinder diameter(mm) |

Cylinder length(mm) |

Dry ore(T/h) |

Ore pulp(m³/h) |

||||||

|

T-GCT0715 |

750 |

1500 |

35 |

According to user requirements and specific mineral properties to determine |

25-30 |

80-120 |

2.2 |

BWD13-43-2.2 |

2100 |

|

T-GCT0718 |

750 |

1800 |

35 |

30-50 |

120-160 |

3 |

BWD13-43-3 |

2500 |

|

|

T-GCT0918 |

900 |

1800 |

25 |

35-50 |

140-200 |

4 |

BWD14-59-4 |

3100 |

|

|

T-GCT0921 |

900 |

2100 |

25 |

40-60 |

160-210 |

4 |

BWD14-59-4 |

3400 |

|

|

T-GCT1015 |

1050 |

1500 |

20 |

35-50 |

140-200 |

4 |

JZQ350-48.57 |

3660 |

|

|

T-GCT1018 |

1050 |

1800 |

20 |

40-60 |

160-210 |

4 |

4150 |

||

|

T-GCT1021 |

1050 |

2100 |

20 |

60-80 |

180-240 |

4 |

4560 |

||

|

T-GCT1024 |

1050 |

2400 |

20 |

70-90 |

200-270 |

5.5 |

JZQ400-48.57 |

5050 |

|

|

T-GCT1030 |

1050 |

3000 |

20 |

80-100 |

260-340 |

7.5 |

ZSY180-50 |

6550 |

|

|

T-GCT1224 |

1200 |

2400 |

17 |

70-95 |

210-280 |

7.5 |

ZSY180-56 |

5500 |

|

|

T-GCT1226 |

1200 |

2600 |

17 |

75-100 |

230-300 |

7.5 |

6000 |

||

|

T-GCT1230 |

1200 |

3000 |

17 |

90-130 |

260-350 |

11 |

6800 |

||

|

T-GCT1232 |

1200 |

3200 |

17 |

95-140 |

280-370 |

15 |

ZSY200-31.5 |

7600 |

|

|

T-GCT1236 |

1200 |

3600 |

17 |

100-160 |

300-390 |

15 |

8200 |

||

|

T-GCT1240 |

1200 |

4000 |

17 |

120-180 |

330-430 |

15 |

8800 |

||

|

T-GCT1245 |

1200 |

4500 |

17 |

135-210 |

370-500 |

15 |

9550 |

||

|

T-GCT1530 |

1500 |

3000 |

13.6 |

|

130-180 |

250-380 |

15 |

ZSY200-40 |

9800 |

|

T-GCT1540 |

1500 |

4000 |

13.6 |

|

150-220 |

350-450 |

18.5 |

ZSY224-40 |

11000 |

|

T-GCT1545 |

1500 |

4500 |

13.6 |

|

180-250 |

380-500 |

18.5 |

12600 |

|

|

T-GCT1560 |

1500 |

6000 |

13.6 |

|

250-300 |

600-750 |

30 |

ZSY250-40 |

15300 |

Note: The technical performance parameters in the above table are determined when the feed grade is 30% and the feed concentration is about 30%. (for reference only)

T-GCT系列高效永磁湿式磁选机.png)

TD系列永磁笼式尾矿回收机.png)

高效细粉筛.png)

T-QCG型干式永磁辊式强磁选机.png)

PC系列永磁盘式尾矿磁选机.png)

NCT系列浓缩磁选机.png)

CTDG系列永磁干式大块磁选机.png)