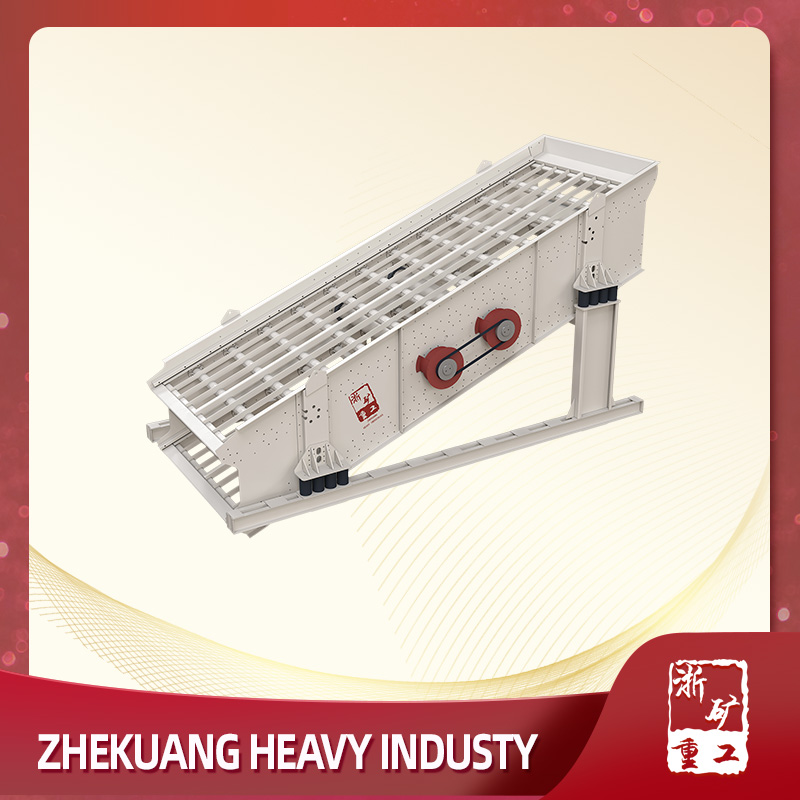

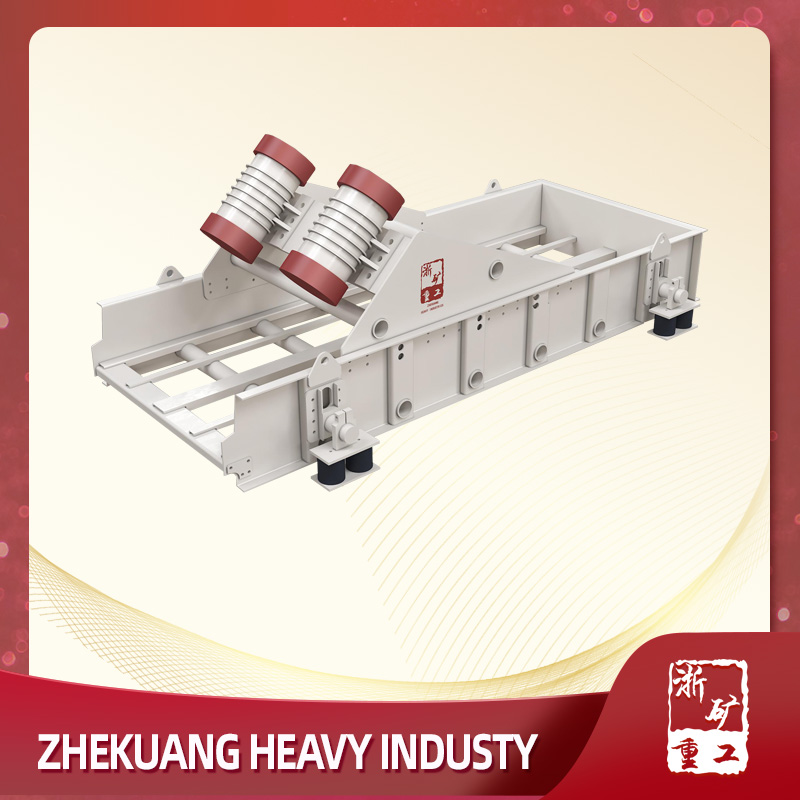

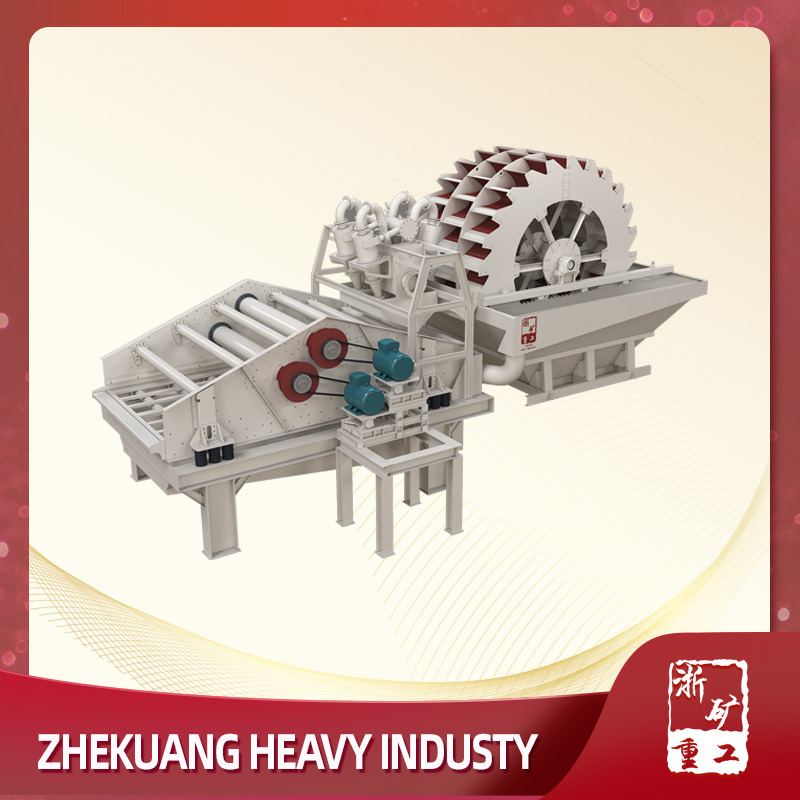

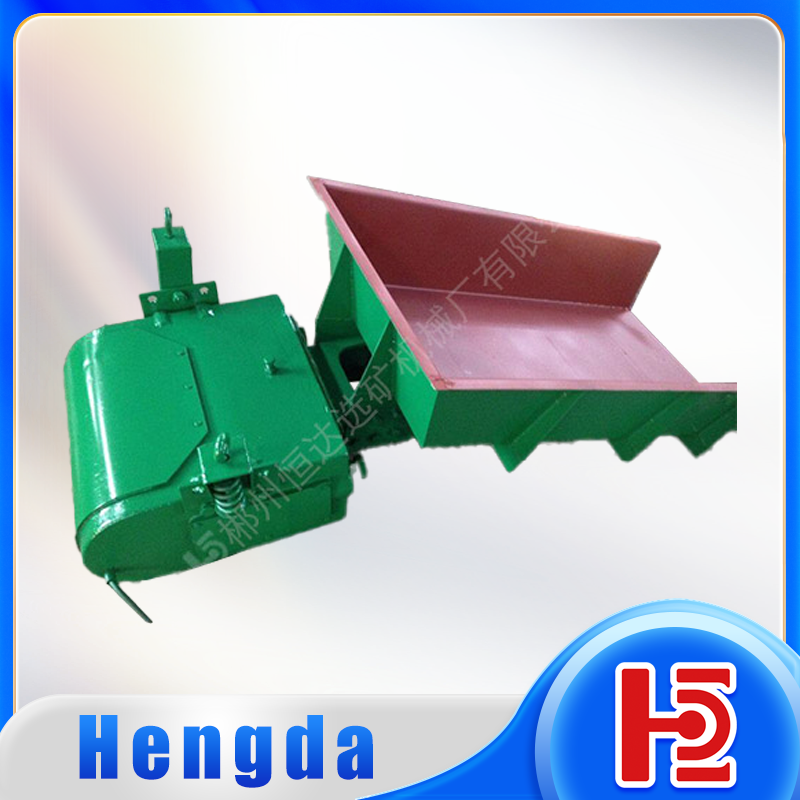

Product Introduction

The GZG linear vibration feeder can uniformly, regularly, and continuously feed block and granular materials from the storage bin to the receiving device in the production process. In the sand and gravel production line, it can continuously and uniformly feed the crushing machinery and coarse screen the materials. It is widely used in crushing, screening, and grading equipment in industries such as metallurgy, coal mining, mineral processing, building materials, chemical engineering, and abrasives.

Performance Characteristics

Smooth vibration, reliable operation, and long service life; It can adjust the excitation force, change and control the flow rate at any time, and the adjustment is convenient and stable; The vibration motor of the GZG linear vibration feeder is the excitation source, with low noise, low power consumption, good adjustment performance, and no material flushing phenomenon. Simple structure, reliable operation, convenient adjustment and installation, light weight, small volume, convenient maintenance. When using a closed structure body, it can prevent dust pollution.

Working Principle

According to the theory of plane sound mass vibration synchronization, when two vibration motors operate in opposite directions at the same angle, the component of their inertial force in the direction of the connecting line at the rotation center of the vibration motor is equal in magnitude and opposite in direction, canceling out each other. The component force perpendicular to the connecting line at the center is in the same direction and overlapping with each other. Under the action of this inertial force, the feeding groove vibrates harmoniously along the direction of the combined force, thereby achieving the purpose of conveying materials.

Technical Parameter

Flat linear vibration feeder

|

Model |

Maximum feed size(mm) |

Processing capacity(t/h) |

Motor power(kw) |

Tilt angle |

Machine weight(kg) |

|

GZG900×3000 |

350 |

260 |

3.2×2 |

8°-12° |

3895 |

|

GZG1150×5000 |

500 |

350 |

5.5×2 |

8°-12° |

5170 |

|

GZG1300×5500 |

700 |

580 |

9×2 |

8°-12° |

7520 |

Bar linear vibration feeder

|

Model |

Maximum feed size(mm) |

Processing capacity(t/h) |

Motor power(kW) |

Tilt angle |

Machine weight(kg) |

|

GZG900×3500 |

350 |

0-320 |

3.2×2 |

5°-12° |

4995 |

|

GZG1150×5000 |

500 |

0-450 |

5.5×2 |

5°-12° |

6585 |

|

GZG1300×5500 |

700 |

0-680 |

9×2 |

5°-12° |

8740 |

|

GZG1400×6000 |

800 |

0-700 |

11×2 |

5°-12° |

9500 |

|

GZG1500×6000 |

850 |

0-900 |

11×2 |

5°-12° |

10500 |