<

>

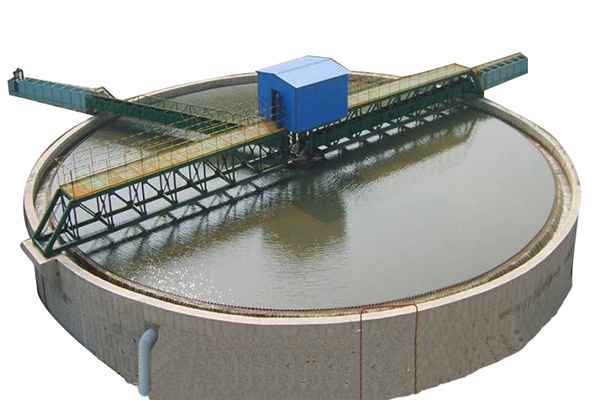

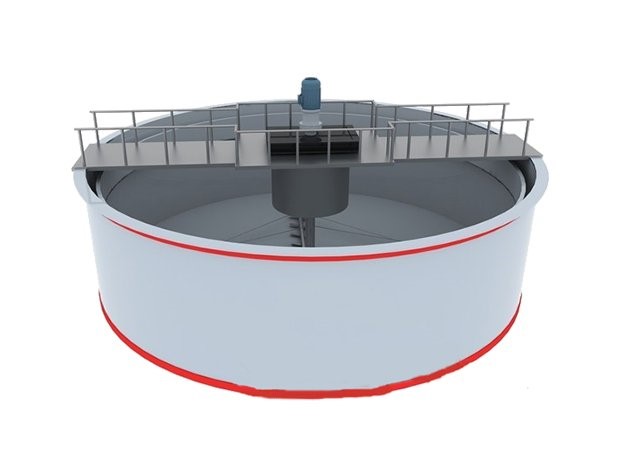

Three-layer Washing and Thickening Machine

Model:

3NZS12

Transmission Mode:

Production Capacity:

≤160t/d

Motor power (kW):

5.5

COLLECT

Shandong Xinhai Mining Technology&Equipment Inc.

Main Products:Ball mill, flotation machine, classifier, thickener, leaching tank, electrolytic system, dewatering screen, autogenous mill/semi-autogenous mill, wet rod mill, vibrating screen, mixing tank, cyclone, wear-resistant rubber slurry pump, graphite-specific stirring mill, feeder, conveyor, rubber sheet, knife gate valve (non-leakage valve), pinch valve, three-way reversing valve, CNC dosing machine, scrubber, dry ball and rod mill, deoxidizing tower, carbon extraction pump, carbon separator screen, air lifter, baffled settler, electromagnetic iron separator, metal detector, flocculant system, electronic belt scale.

Enter the store

︿

﹀

Details Parameters

Related product recommendations

More Products >