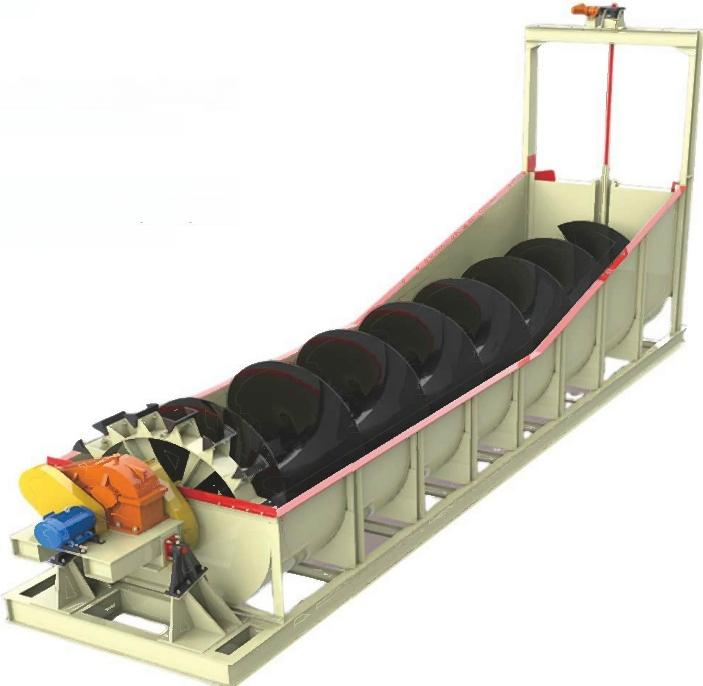

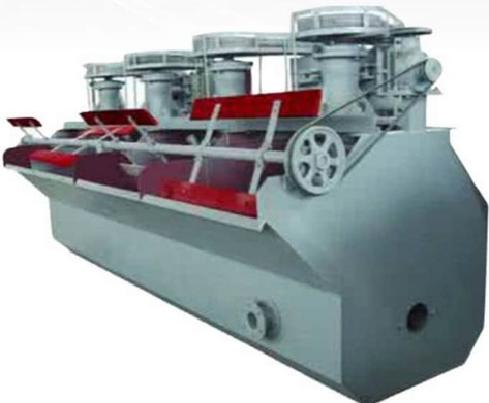

The JJF flotation machine is a mechanical agitation flotation equipment, which can be widely used for the separation of non-ferrous metals, ferrous metals, and non-metallic minerals. It has the ability to self-prime air but no ability to self-prime slurry. Equipment units need to be configured in steps (with a drop of 300-400 mm). It can form a combined flotation unit with the SF-type flotation machine, where the SF-type serves as the suction tank and the JJF-type as the direct-flow tank. It mainly consists of a tank body, impeller, stator, dispersion hood, false bottom, guide pipe, vertical cylinder, regulating ring, etc. When the impeller rotates, a vortex is generated in the vertical cylinder and guide pipe, creating negative pressure that sucks air in through the intake pipe. The air mixes with the slurry sucked in through the guide pipe in the impeller and stator area. The slurry-air mixture flow is set in tangential motion by the impeller, then converted to radial motion by the stator, and evenly distributed in the flotation tank. Mineralized bubbles rise to the froth layer and are scraped off from one or both sides to become the froth product.

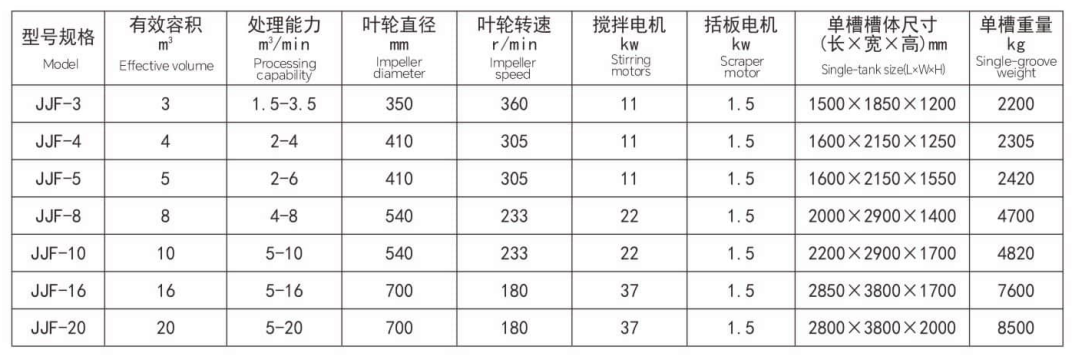

Main models and technical parameters