Product Introduction

Humanized design for more convenient production and use.

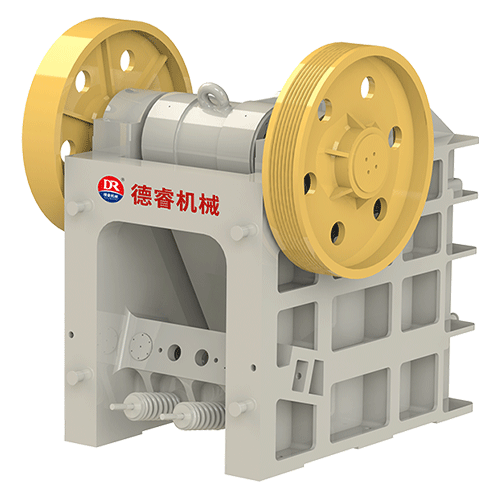

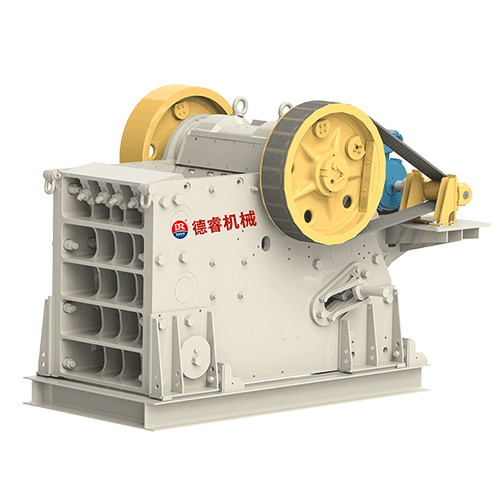

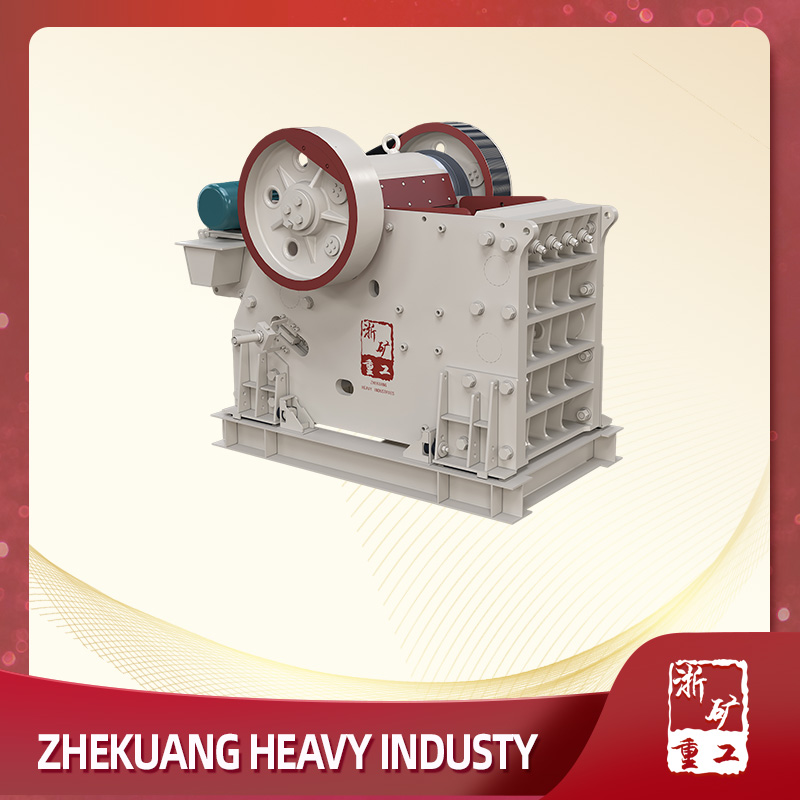

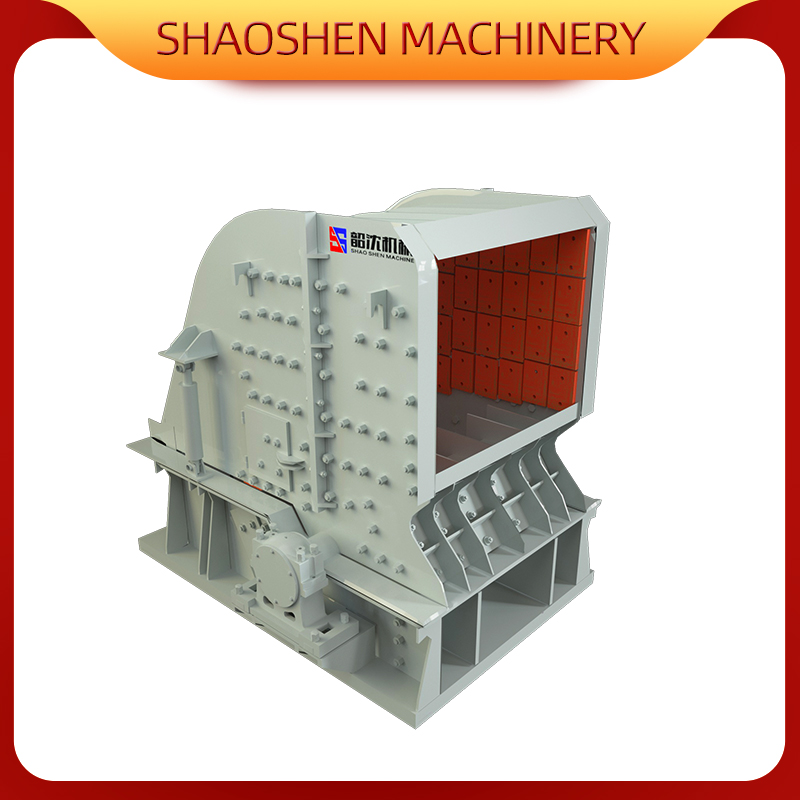

Simple and robust structure, highly durable and resistant to damage, with a compact footprint, making it especially suitable for fixed crushing production lines and mobile crushing stations.

As a key equipment for primary crushing in the crushing process, the jaw crusher is one of our core products and has a long-standing history in our company. Over the years, we have focused on the R&D and manufacturing of high-performance crushers, supported by thousands of customer sites. Through multiple iterations and upgrades, combined with the introduction of advanced European technology, we have developed the SC series European-style jaw crusher, which stands at a high level in the market.

Compared to traditional jaw crushers, the SC series European-style jaw crusher has made significant improvements in motion parameters, structural design, and adjustment methods. It adopts an innovative modular, weld-free frame structure, high-quality alloy steel castings, and rolling bearings, greatly enhancing fatigue resistance and operational reliability. This ensures high productivity, efficiency, and low-cost crushing operations. Multiple flexible installation options cater to various application needs.

Working Principle

The SC series European-style jaw crusher operates with a curved extrusion mechanism. The working principle is as follows: the motor drives the belt and pulley, causing the eccentric shaft to move the movable jaw up and down. When the movable jaw rises, the angle between the toggle plate and the movable jaw increases, pushing the movable jaw plate toward the fixed jaw plate, crushing or splitting the material. When the movable jaw descends, the angle decreases, and the movable jaw plate moves away from the fixed jaw plate under the action of the pull rod and spring, allowing the crushed material to discharge from the lower opening of the crushing chamber. With the continuous rotation of the motor, the movable jaw performs periodic crushing and discharging, enabling batch production.

Performance Features

01 Optimized Motion Parameters

Superior motion parameters enable crushing to begin in the upper part of the crushing chamber, with a larger stroke in the lower part for a greater crushing ratio.

02 Oversized Bearing Design

Compared to previous jaw crushers of the same specification, the bearing size is enlarged, extending service life. The four bearings in the movable jaw and frame share the same specifications, reducing spare part variety.

03 Modular Adjustment Method

The discharge port adjustment differs from the traditional shim-based method, adopting a modular approach to reduce labor intensity and downtime. Users can optionally equip a hydraulic adjustment device for easier operation.

04 Steel Toggle Plate

The toggle plate is made of high-strength steel plate. In case of overload, it bends and deforms to protect critical components, unlike traditional cast iron toggle plates. It is lighter, easier to replace, and avoids damage to conveyors caused by broken cast iron toggle plates.

05 Integrated Motor Base Structure

The motor base and main unit form an integrated structure, simplifying installation and saving space. The entire machine is placed on a steel frame base, with shock-absorbing pads between the main unit and the base to minimize impact on the foundation.

06 Non-Welded, Disassemblable Frame

The SC European-style jaw crusher frame features side plates, front wall plates, and rear beams connected by cylindrical pins and bolts, eliminating the stress concentration issues common in welded frames for enhanced durability and reliability.

Technical Parameters

| Model | C80 | C96 | C110 | C125 | C140 | C160 | |

| Feed Opening Width(mm) | 800 | 960 | 1100 | 1250 | 1400 | 1600 | |

| Feed Opening Length(mm) | 510 | 650 | 850 | 950 | 1070 | 1200 | |

| Motor Power(kW) | 75 | 90 | 110 | 185 | 220 | 280 | |

| Rotational Speed(r/min) | 325 | 290 | 250 | 240 | 220 | 220 | |

| Product Size(mm) | Closed Side Setting(mm) | (t/h) | (t/h) | (t/h) | (t/h) | (t/h) | (t/h) |

| 0-30 | 20 | ||||||

| 0-35 | 25 | ||||||

| 0-45 | 30 | ||||||

| 0-60 | 40 | 60-90 | |||||

| 0-75 | 50 | 75-100 | |||||

| 0-90 | 60 | 90-120 | 85-110 | ||||

| 0-105 | 70 | 1104145 | 100-130 | 195-255 | |||

| 0-120 | 80 | 125-165 | 120-155 | 215-280 | |||

| 0-135 | 90 | 145-190 | 135-175 | 240-310 | |||

| 0-150 | 100 | 160-210 | 160-200 | 260-335 | 295-385 | ||

| 0-185 | 125 | 205-270 | 170-220 | 315-410 | 355-460 | 390-505 | |

| 0-225 | 150 | 245-330 | 215-280 | 375-485 | 415540 | 460-595 | 525-580 |

| 0-260 | 175 | 285-375 | 255-335 | 430-555 | 475-615 | 525-680 | 600-780 |

| 0-300 | 200 | 290-380 | 485-630 | 535-695 | 595-770 | 680-885 | |

| 0-340 | 225 | 595-775 | 660-855 | 755-980 | |||

| 0-375 | 250 | 655-850 | 730-950 | 830-1080 | |||

| 0-410 | 275 | 905-1175 | |||||

| 0-450 | 300 | 985-1280 | |||||

复摆型鄂式破碎机2.png)