Purpose and Application Scope of the Equipment

DG series vertical high-pressure double-roll sand-making machine is suitable for intermediate and fine crushing of materials with high hardness (such as granite, marble, mineral stone, corundum, etc.) and medium-hard brittle ores (such as sandstone, limestone, construction waste, etc.). The feed particle size is ≤35 mm. By adjusting the pressure between the two rollers, different discharge particle sizes can be obtained: coarser discharge particle sizes result in higher output, while finer discharge particle sizes result in lower output.

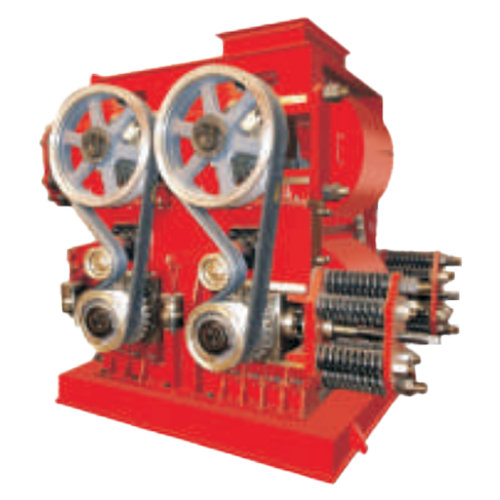

Working Principle of the Equipment

The roll crusher consists of major components such as the frame, upper frame section, lower frame section, reduction gear, and drive unit. A motor drives the two rollers to rotate in opposite directions at equal speeds through a reduction device. When materials enter the gap between the rollers from the hopper, the relative rotation of the rollers squeezes the materials between them, achieving the crushing effect.

Comparison of Advantages and Disadvantages of the DG Series Vertical High-Pressure Roll Sand-Making Machine

- Common Models in the Market (Horizontal Type)

There are several horizontal roll crushers available in the market, but they share the following drawbacks:

- Due to the plane movement of the horizontal roll crusher rollers, the self-weight pressure of the rollers causes unnecessary stress and wear on the slide rails, significantly reducing stability.

- Since the rollers of horizontal roll crushers move on a flat plane, overall sagging and wear are likely to occur, necessitating extensive repairs to the sliding surface, which is difficult to perform.

- The springs or hydraulic jacks of horizontal roll crushers are oriented horizontally, greatly diminishing operational performance.

- Horizontal roll crushers require additional work to overcome the weight and slide rails, leading to relatively high energy consumption losses.

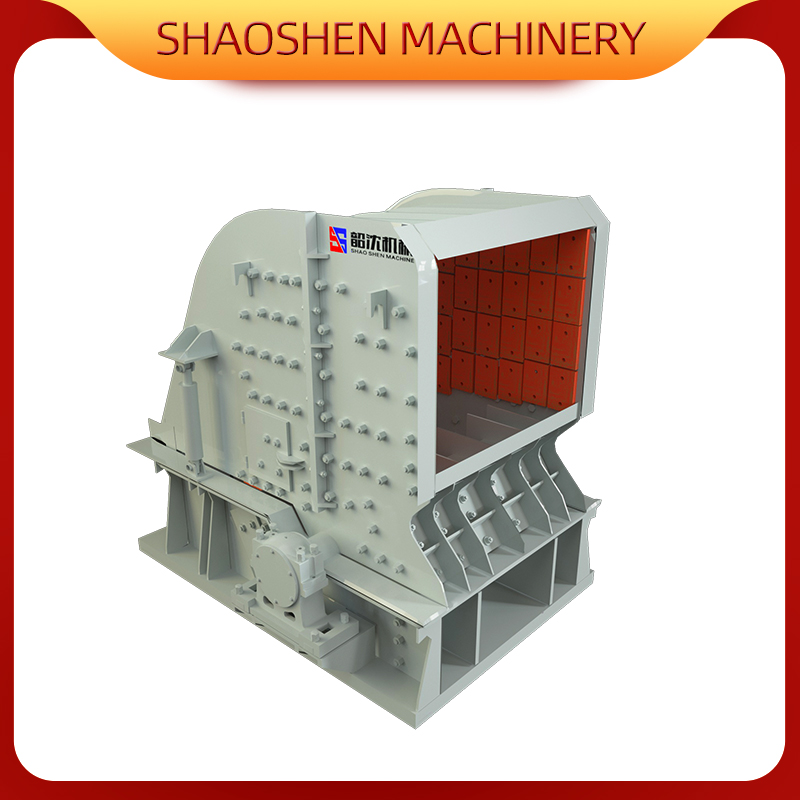

- Shaoshen New DG Vertical Roll Crusher

This invention leverages the advantages of the vertical design to improve upon the above shortcomings:

- The invention alters the positional relationship of the driving and driven wheels, positioning them vertically, and connects them via a rotating shaft and bronze bushing, which is lubricated with grease to ensure long-term stable operation.

- When wear reaches its limit after prolonged use, only the rotating shaft and bronze bushing need replacement, significantly reducing maintenance costs and difficulty.

- The vertical arrangement of the driving and driven rollers converts their self-weight into energy for crushing and sand-making, reducing energy consumption while improving crushing efficiency.

- The invention employs a composite spring and hydraulic cylinder for vertical pressure application, forming a high-pressure system. The composite spring is responsible for damping and eliminating resonance, achieving an efficient and stable structure.

- The control system uses a PLC to regulate speed and oil pressure, enabling customers to achieve the desired stone particle size and powder rate.

Main Technical Parameters

| Model | Roller Size (mm) | Feed Size (mm) | Roller Speed (r/min) | Capacity (t/h) | Power (KW) | Weight (T) | Overall Dimensions (mm) |

| DG600*900 | φ600*900 | 15 | 40~120 | 40-80 | 110 | 17 | 3805*2810*3150 |

| DG900*1200 | φ900*1200 | 20 | 30~100 | 80-180 | 185 | 31 | 5295*3220*3696 |

| DG1200*1600 | φ1200*1600 | 30 | 30~80 | 120~250 | 315 | 41 | 6320*3950*4150 |

2GSP型对辊破碎机.png)