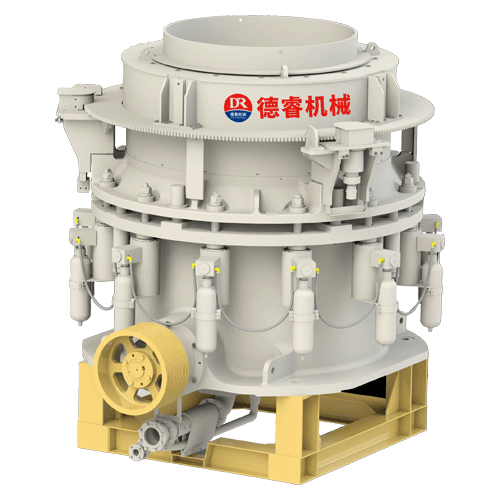

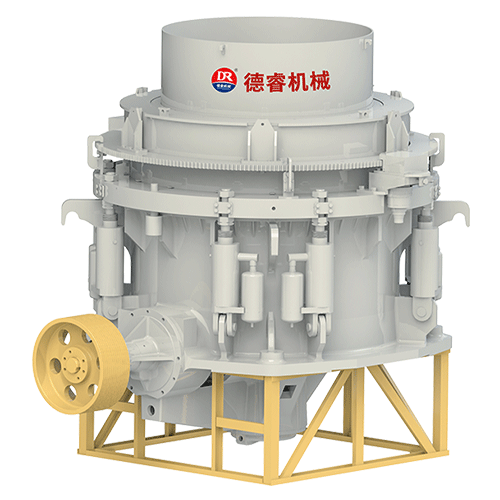

Product Introduction

H Series High Performance Multi-Cylinder Hydraulic Cone Crusher is developed based on absorbing the world's advanced crushing technology and Shaoshen Machinery's years of accumulated crushing experience. It is a fully hydraulic cone crusher with high efficiency and high performance, which can be widely used in industrial enterprises such as metallurgy, construction, hydropower, transportation, chemical industry, and building materials.

Compared with similar products, H Series High Performance Multi-Cylinder Hydraulic Cone Crusher features a novel and unique structure, more reliable performance, safer operation, and more convenient maintenance. The machine adopts a hydraulic drive mechanism, which can quickly adjust the discharge opening size, facilitating the adjustment of the crushing circuit to achieve balanced production and maximize the crusher's efficiency. With multiple crushing chamber types, it can perform crushing operations from standard, medium to short-head configurations, adapting to a wide range of product size requirements. It is suitable for crushing various ores and rocks with hardness ranging from medium to high.

The hydraulic system is convenient and reliable, providing safe and effective overload protection. The use of hydraulic adjustment and hydraulic chamber clearing settings greatly improves automation, thereby reducing or even avoiding downtime, significantly reducing workers' workload, and greatly lowering production costs.

Practice has proven that H Series High Performance Multi-Cylinder Hydraulic Cone Crusher is a new type of high-performance multi-cylinder hydraulic cone crusher.

Advantages and Features

- More reliable performance

- Novel and unique structure

- Intelligent system

Applicable Materials

River pebble, limestone, dolomite, granite, diabase, basalt, ferrous metals, etc.

| Model & Specifications | Crushing Diameter (mm) |

Feed Opening Size(mm) | Minimum Discharge Opening (mm) |

Motor (kW) |

Weight (T) |

Overall Dimensions | Discharge Opening Size | Capacity | ||

| Closed Side | Open Side | |||||||||

| H400 | Short Head | 70 | 90 | 8 | 220 | 52.8 | 4210×2895×3700 | 13-25 | 120-300 | |

| Medium | 135 | 190 | 13 | 52.8 | 4210×2895×3700 | 20-35 | 200-450 | |||

| Standard | 150 | 225 | 26 | 53.3 | 4210×2895×3700 | 30-50 | 300-680 | |||

| H600 | Short Head | 127 | 178 | 13 | 400/450 | 86 | 5632×3320×4632 | 13-25 | 280-695 | |

| Medium | 303 | 334 | 25 | 86 | 5632×3320×4632 | 25-51 | 400-1160 | |||

| Standard | 425 | 460 | 38 | 86 | 5632×3320×4632 | 38-64 | 710-1550 | |||

| H900 | Short Head | Fine | 60 | 120 | 10 | 710 | 161 | 7937×4200×5098 | 10-16 | 560-670 |

| Medium | 100 | 150 | 13 | 161 | 7937×4200×5098 | 13-19 | 670-810 | |||

| Coarse | 130 | 190 | 16 | 161 | 7937×4200×5098 | 16-22 | 770-1000 | |||

| Extra-Coarse | 160 | 220 | 19 | 161 | 7937×4200×5098 | 19-25 | 920-1190 | |||

| Medium | Fine | 245 | 330 | 45 | 161 | 7937×4200×5098 | 45-250 | 700-1200 | ||

| Medium | 280 | 375 | 60 | 161 | 7937×4200×5098 | 60-250 | 1050-1900 | |||

| Coarse | 380 | 465 | 70 | 161 | 7937×4200×5098 | 70-250 | 1300-2500 | |||

| Extra-Coarse | 400 | 495 | 80 | 161 | 7937×4200×5098 | 80-250 | 1500-2600 | |||

多缸液压圆锥破碎机.png)