<

>

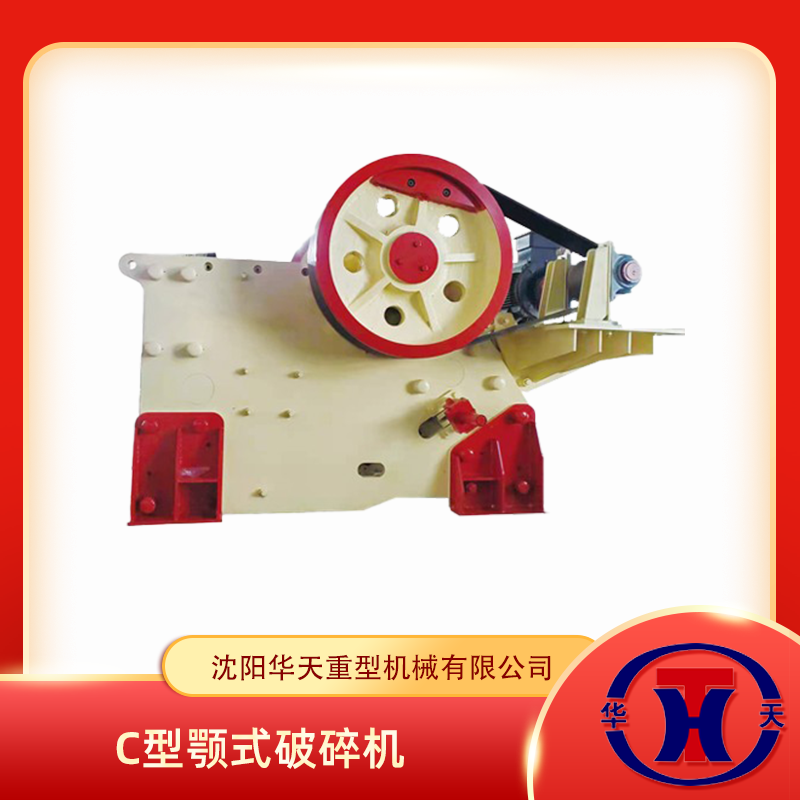

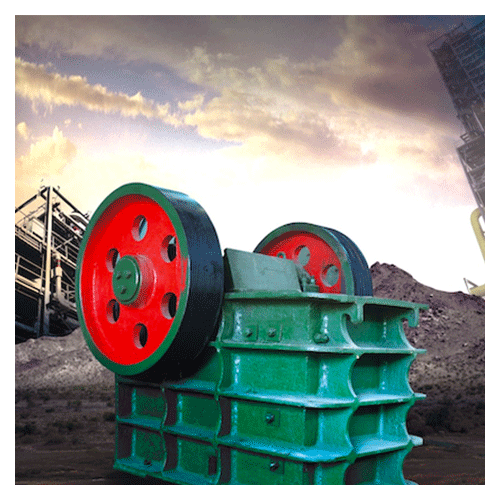

Jaw Crusher

Model:

PEV500*750

Size of Feeding Port:

500*750mm

Maximum Feed Particle Size:

Throughput:

55-340t/h

COLLECT

Shenyang Guangzhong Mining Machinery Equipment Co., Ltd

Main Products:Single cylinder crusher, multi cylinder crusher, spring cone crusher, jaw crusher, sand making machine

Enter the store

Details Parameters

Related product recommendations

More Products >

Shenyang Henuode Machinery Equipment Co., Ltd

.png)

lQDPJxao3EKSoEvNA3bNB4CwQanrU4panT4DFbonGYAGAA_1920_886.png)

.png)

微信图片_202111161411161.png)

PE鄂式破碎机.png)

冲击式破碎机1.png)