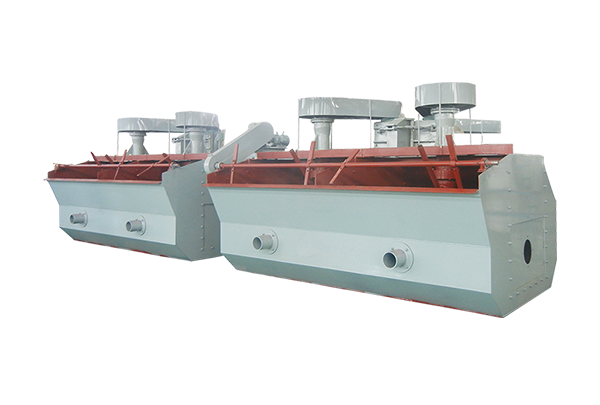

With unparalleled metallurgical performance, high availability, and minimal footprint, the TankCell flotation machine consistently leads the flotation industry, all of which play a critical role in enabling us to deliver on our "Metso Outotec Pioneer" vision.

Product Advantages

Metso Outotec's TankCell® flotation machine is based on forced air technology, delivering superior metallurgical and mineral processing performance, along with ease of operation and flexible arrangement.

Our solutions are designed to maximize return on investment by improving throughput, grade, and recovery while enhancing the sustainability of production processes and minimizing environmental impact.

- Lower energy consumption

- Smaller plant footprint

- Higher operational availability

- Reduced need for auxiliary equipment

- Proven superior metallurgical performance across various flotation applications

- Lower total investment cost

- Simplified operation and maintenance

World-Class Flotation Performance

The industry-leading TankCell series delivers the world's best flotation performance and the broadest range of flotation machine sizes, ranging from 5 m³ to 630 m³.

Our flotation machines ensure excellent performance in rougher, scavenger, and cleaner applications. Leveraging extensive testing capabilities, we can tailor flotation circuit designs to achieve optimal flotation volume, froth carrying rate, and retention time.

Wide Range of Flotation Machine Sizes

TankCell flotation machines are built to last. For example, Metso Outotec's rotor and stator offer the longest wear life on the market today.

These flotation machines are easy to operate, consume low power and air, and allow for modular arrangement.

With sizes up to 630 m³, the wide range of flotation machines enables compact, cost-efficient, and high-performance plant designs without short-circuiting risks—even in today's high-tonnage mineral processing systems. Fewer installed units mean significant savings in construction, piping, cabling, instrumentation, and auxiliary equipment costs.

|

|

Effective volume |

Drive type |

Installed power |

Aeration volume per shaft |

Air pressure |

||||

|

|

m3 |

ft3 |

|

kW |

HP |

Am³/min |

ACFM |

kPag |

psig |

|

TankCell e5 |

5 |

176 |

V-belt |

11 |

15 |

2 |

75 |

20 |

2.3 |

|

TankCelle10 |

10 |

352 |

V-belt |

22 |

30 |

4 |

149 |

25 |

3.6 |

|

TankCell e20 |

20 |

705 |

V-belt |

37 |

50 |

6 |

224 |

31 |

4.5 |

|

TankCell e30 |

30 |

1057 |

V-belt |

45 |

60 |

8 |

298 |

36 |

5.3 |

|

TankCell e50 |

50 |

1762 |

V-belt |

55 |

75 |

13 |

484 |

34 |

5 |

|

TankCell e70 |

70 |

2467 |

V-belt |

75 |

100 |

18 |

671 |

36 |

5.2 |

|

TankCell e100 |

100 |

3525 |

V-belt/ Gear reducer |

110 |

150 |

24 |

894 |

39 |

5.7 |

|

TankCell e130 |

130 |

4582 |

V-belt/ Gear reducer |

132 |

200 |

28 |

1043 |

45 |

6.6 |

|

TankCell e160 |

160 |

5639 |

Gear reducer |

160 |

200 |

32 |

1192 |

47 |

6.9 |

|

TankCell e200 |

200 |

7049 |

Gear reducer |

185 |

250 |

36 |

1341 |

52 |

7.6 |

|

TankCell e300 |

300 |

10574 |

Gear reducer |

250 |

350 |

42 |

1565 |

65 |

9.4 |

|

TankCell e500 |

500 |

17623 |

Gear reducer |

400 |

550 |

58 |

2161 |

63 |

9.2 |

|

TankCell e630 |

630 |

22245 |

Gear reducer |

500 |

700 |

73 |

2720 |

66 |

9.6 |

Parts and Services

1. Flotation Machine Upgrade

We upgrade your existing flotation process technology with solutions that deliver measurable value or refurbish flotation machines from other manufacturers.

2. Flotation Machine Center Launder Upgrade

The Metso center launder upgrade significantly improves critical flotation performance metrics: froth recovery. To ensure optimal flotation performance, both the enrichment zone recovery and froth recovery must operate efficiently.

3. Mining Equipment Maintenance and Repair

Equipment maintenance and repair slow down aging to help you achieve your production goals. We offer a range of mining equipment maintenance and repair services, from single inspections to comprehensive turnkey projects, providing nearby support whenever you need it.

4. Lifecycle Services for the Mining Industry

Metso lifecycle services and performance solutions deliver a tailored portfolio of mining services to help you achieve optimal performance and sustainable outcomes.

47ad23a1-8240-4059-8bd3-486b248540ee屏幕截图-2021-08-26-180012.png)