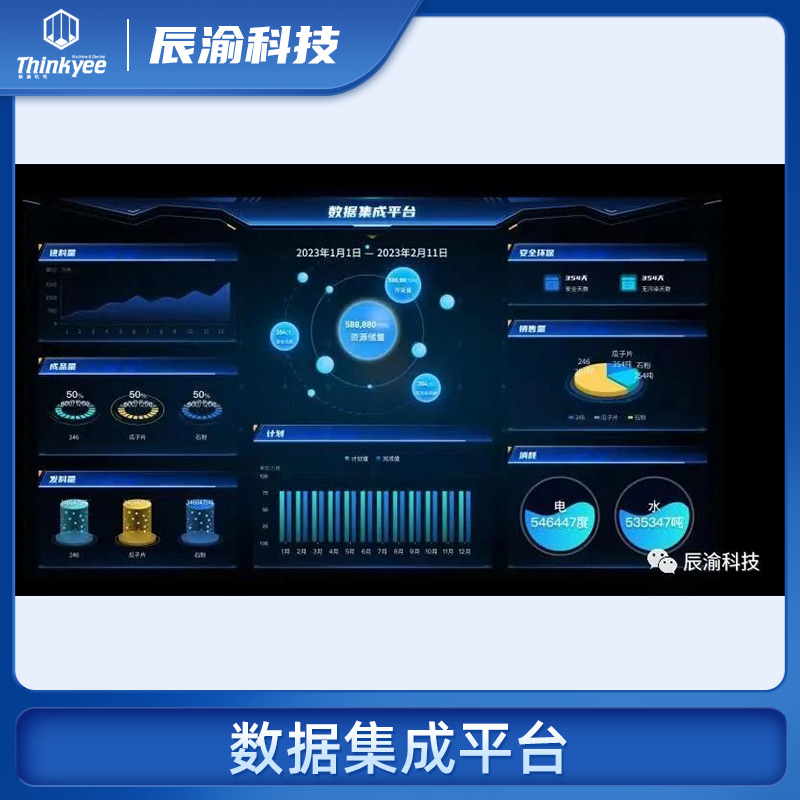

Establish an intelligent control system for the entire process of mining, shovel loading, transportation, ore distribution, processing, and sales, achieving effective connection of various production links. Concentrate the scattered production control rooms in the central control room for unified production, scheduling, and management, achieving centralized control of the entire process and maximizing production efficiency.

The main data provided by the platform includes:

Feed volume: excavator, utilization rate of mining trucks (unit efficiency: tons/hour), unloading data from mining trucks to unloading points.

Inventory: The utilization rate of the material warehouse (raw material warehouse and finished product warehouse), (analyzing the smoothness of the production process), real-time inventory and volume of each material warehouse.

Production efficiency: The operational efficiency of the production line (unit efficiency: tons/hour), unit efficiency.

Finished product quantity: displays the total quantity of finished products and the weight of each product category, as well as the quantity and total quantity of each finished product.

Finished Product Yield: displays the distribution ratio of finished product yield and product categories (whether they match the plan), yield.

Sales volume: Real time quantity of loading and shipment, compared to the relationship between production inventory and incoming materials, real-time quantity and total quantity of loading and shipment.