For Class A mines, the optimal ore blending plan is formulated based on the geological grade and production requirements for ore grade. When the key quality indicators of the mining area do not meet the quality control requirements, the system should be able to automatically provide suggestions on the location and quantity of the mining area that needs to be peeled off or transferred, provide the best mining and quality blending plan, and achieve maximum resource utilization efficiency and product quality optimization. Ordinary construction stone mines (excluding basalt mines produced by dry methods) should be equipped with cross band particle size analyzers to detect the proportion of sand and gravel aggregates of different specifications in real time, and achieve reasonable product distribution.

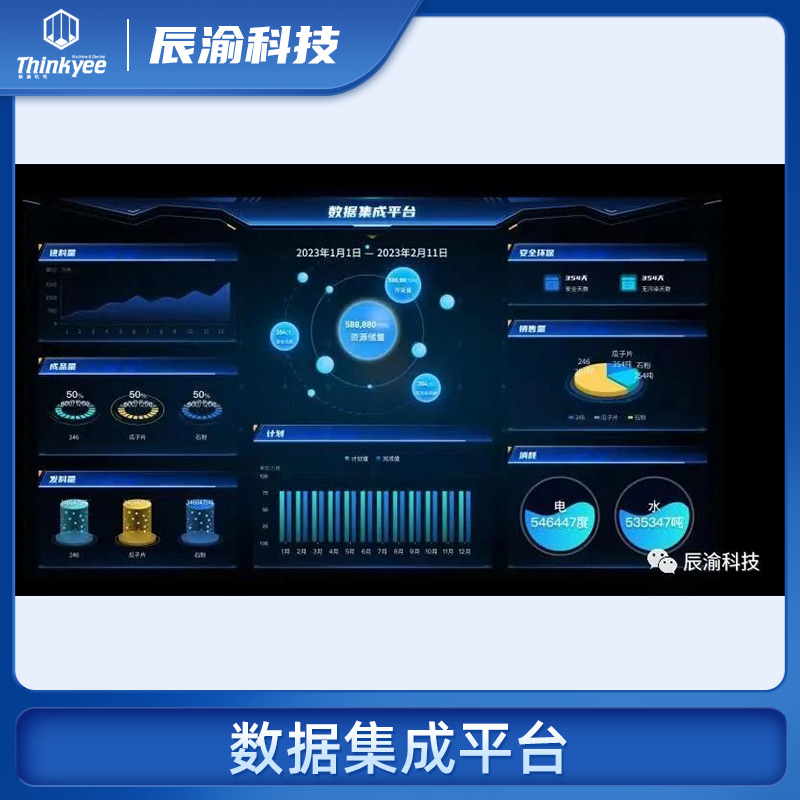

The real-time transmission of cross band analyzer detection data to the data integration platform forms the original record of detection results, and at the same time, production data can be synchronously entered. (Dening Mine belongs to the category of ordinary building stone mines)