The significance of this system lies in solving six major problems during the transportation of mining vehicles at the machine port:

1. Unattended weighing scales, reducing the number of staff in the weighing room;

2. Effectively prevent vehicle driving speed;

3. Effectively prevent vehicle overloading;

4. Reduce the workload of vote counting personnel;

5. Avoid excessive human intervention in vote counting work;

6. Improve the collaborative efficiency of mining truck excavators and increase the loading capacity of raw materials;

7. Vehicle driving safety control.

The system can record the actual transportation time of vehicles from different mining areas to the airport entrance, determine whether the vehicle is speeding during the process of driving to the airport entrance, and record the speeding information in the system to form an overload record, providing data basis for fleet management.

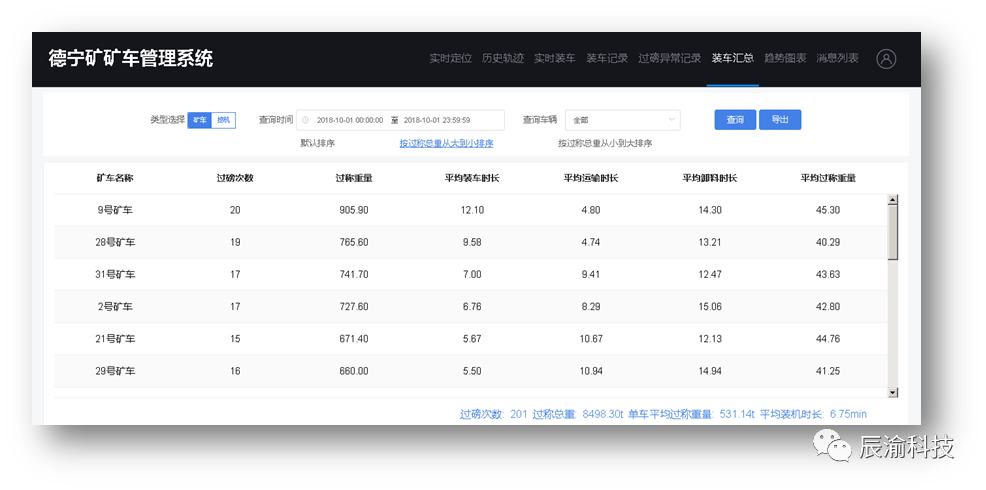

Collection of carrying weight data:

The system can record the weight of each vehicle weighing, which can not only serve as the data basis for the work performance of truck drivers and excavator drivers, but also determine whether the vehicle is overloaded during the loading process through this weight. The overload information can be sent to truck drivers and excavator drivers, and recorded in the system to form an overload record, providing data basis for fleet management.

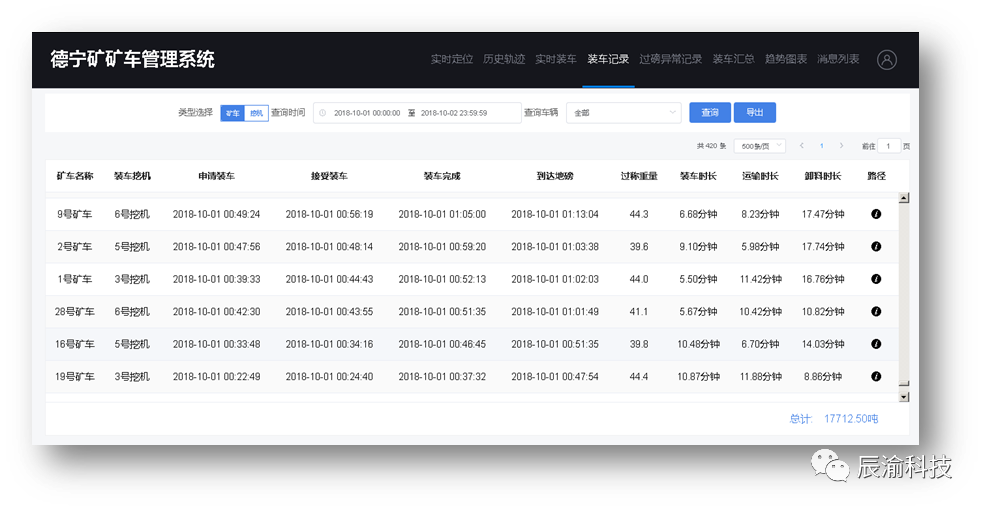

Statistics of mining car tickets:

By automatically detecting the operation process of mining trucks (waiting, loading, fully loaded, loaded, empty), it is possible to accurately, real-time, and automatically count the number of tickets and tons per vehicle in combination with data collection modules.

Excavator performance management:

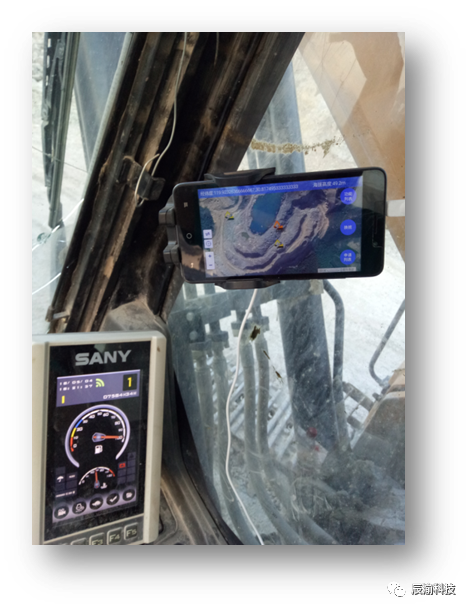

Through the intelligent terminal installed on the vehicle, the mining truck and excavator drivers do not need to perform any operations. The system automatically obtains the working status of the mining truck and excavator through backend algorithms, such as loading in progress, waiting for loading, or fully loaded.

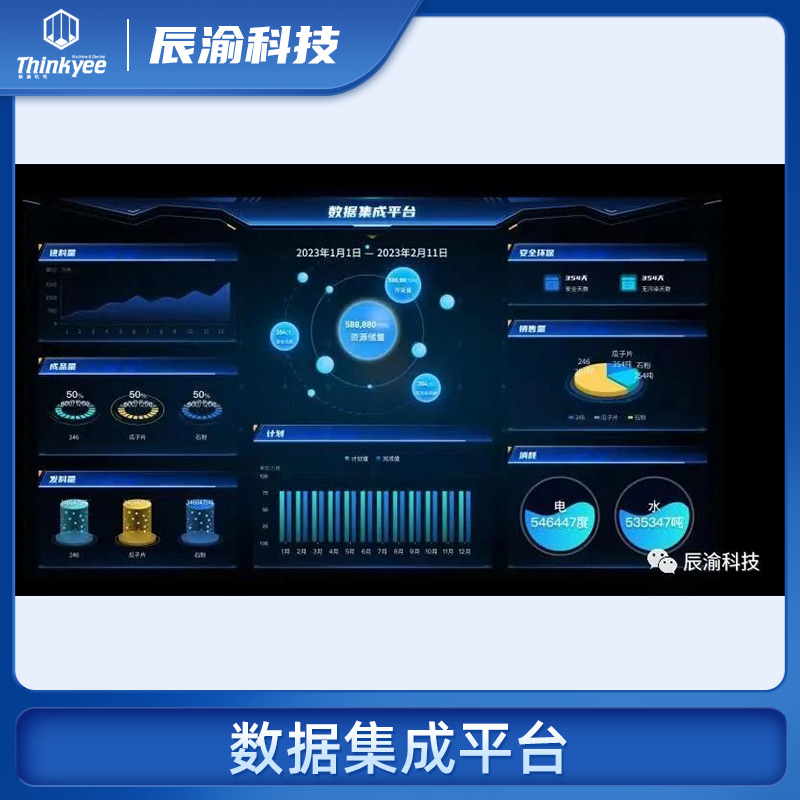

Software features:

Ticket recording, ticket statistics, system message management, mining vehicle empty load control, real-time vehicle positioning, system data analysis, and remote viewing.