In recent years, with the rise of the concept of intelligent manufacturing, mining enterprises have increased their transformation and upgrading towards digitization, informatization, and intelligence.With the "Two Mountains Theory" proposed by General Secretary, the demand for green, environmental protection, and safety construction in the mining industry has become stronger. Digitalization, intelligence, and unmanned mining have become the necessary path for mining enterprises to build green mines.

The smart mining digital twin model first needs to understand what digital twin is. Digital twin fully utilizes physical models, sensor updates, operating history and other data, integrates multi-disciplinary, multi physical quantities, multi-scale, and multi probability simulation processes, completes mapping in virtual space, and reflects the full lifecycle process of corresponding physical equipment.

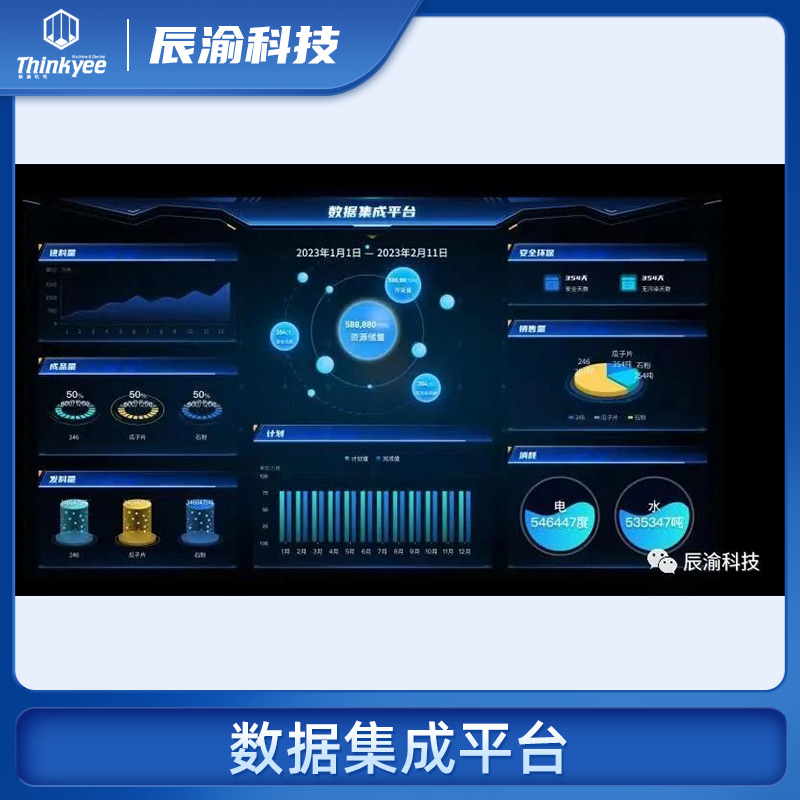

Digital twin is a concept that transcends reality and can be seen as a digital mapping system of one or more important, interdependent equipment systems. From the definition of digital twins, we can see that it mainly involves a combination of two aspects: one is the physical model, and the other is the data display. In layman's terms, it means displaying corresponding data on top of the model. The smart mining digital twin model displays the main core data of the mine on the three-dimensional model of the real scene of the mine.

The realistic 3D model of a mine is a product of the combination of 3D GIS, realistic models, and 2D flat maps. It is more realistic than the original method of constructing a 3D model, and can more realistically reflect the real production environment. Web conversion makes it more convenient and fast in display, providing a good carrier for the next step of data display.

The core data of the real scene 3D model display mainly includes several aspects:

- Feed data

- Equipment working condition data

- Finished product production data

- Dock loading sales data

- Mining environmental data

- Personnel and vehicle positioning

- Real-time side slope data

- Real-time data for boundary data mining and transportation

- Alarm Center