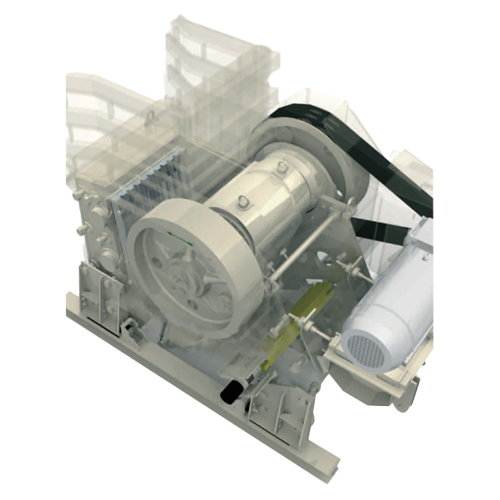

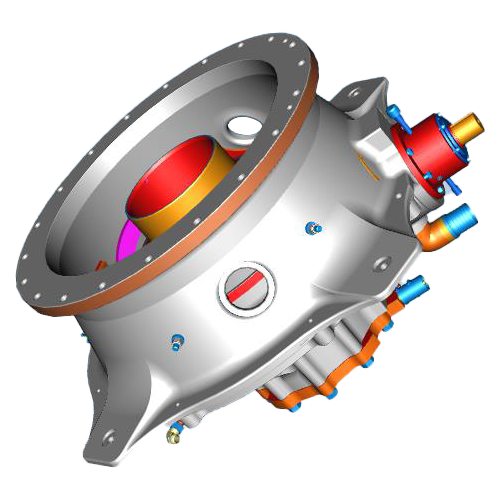

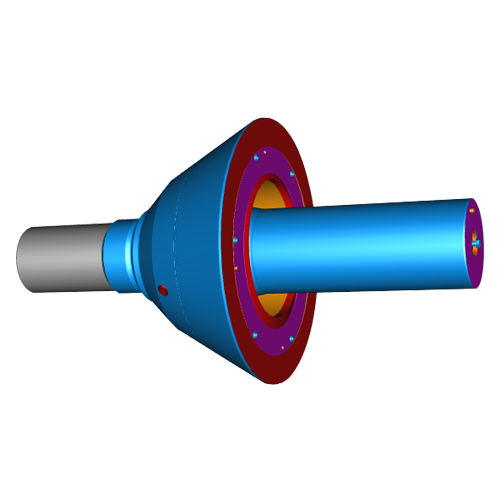

Applicable Main Machine Types

(4265/5065/5475/6275/6089/7089/60110 and various types of gyratory crushers)

Performance Advantages

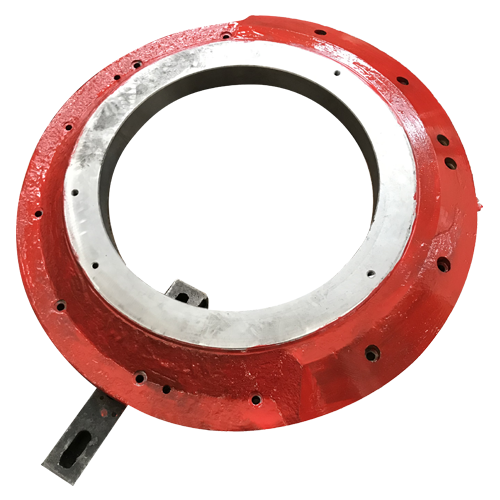

1. Real-Time Monitoring of Liner Usage: The system monitors the wear of liners in real-time and provides timely replacement reminders.

2. Automatic Iron Ejection: It monitors the main motor current and moving cone pressure in real-time, automatically ejecting iron pieces during equipment operation.

3. Fault Diagnosis and Reduced Downtime: By monitoring critical parts of the hydraulic and lubrication systems, such as oil level, oil temperature, oil pressure, flow rate, and moving cone position, the system enables quick fault diagnosis, significantly reducing downtime.

4. Real-Time Coupling Speed Monitoring: The system monitors coupling speed in real-time, automatically alarming and shutting down in case of belt slippage or motor failure.

5. Bearing Temperature Monitoring: It monitors the transmission shaft bearing temperature in real-time, promptly detecting anomalies and performing timely maintenance to extend bearing life.

6. Material Level Monitoring in the Feed Bin: The system monitors the material level in the feed bin in real-time to prevent blockages and ensure safe operation of the main machine.

7. Networking Functionality: The system can be networked for remote real-time monitoring of equipment operating status. The accumulated historical data can be used for retrospective analysis and process optimization.