Detailed Introduction

1. DCS (Distributed Control System) central control system’s video system and industrial control system are on two separate networks, ensuring no interference between them. Similarly, the industrial control system and the company's office information network are also on separate networks. Using isolation routing technology, data transmission and communication between the office, industrial control, and video monitoring systems can be provided as needed. The video host is placed in the crushing control room.

All video cameras are networked, high-definition, and fully enclosed. For distances over 80 meters or outside the plant, fiber optic networking is used, and camera power is supplied by the Santak UPS power system, providing effective protection for the video monitoring system.

2. All control systems are powered by the SANDVIK UPS, ensuring one hour of power supply after a power outage.

3. The system is equipped with lightning protection functions.

4. All modules of the industrial control automation system use Siemens components.

5. All cameras are Hikvision brand.

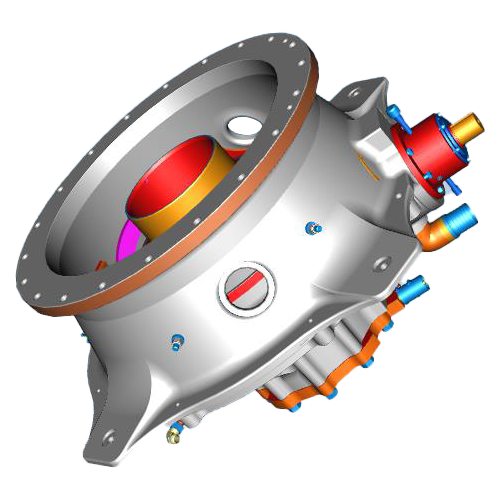

Performance Advantages

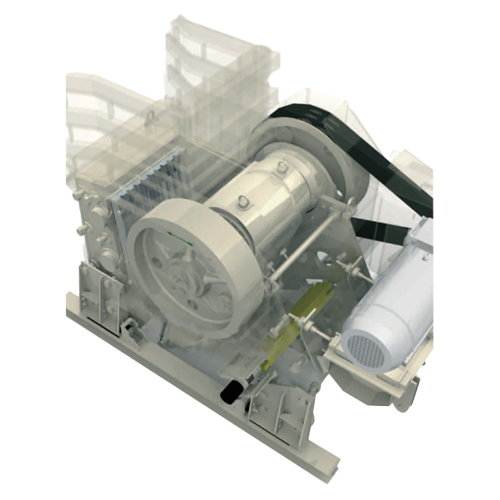

1. Centralized Control and Monitoring: Centralized control and status monitoring of the production line significantly reduce the need for on-site workers. Automatic measurement of conveyor belt output prevents production cheating, saving time and labor.

2. Adaptive Feeding Power: This function optimizes production line load adjustment, avoiding energy waste and reducing consumption.

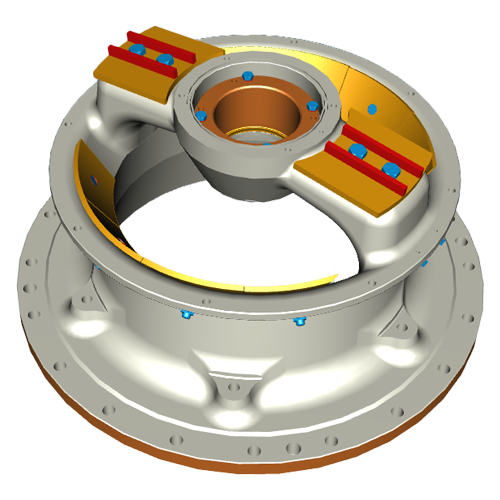

3. Protection and Monitoring Functions: Features such as iron protection, current monitoring, bearing temperature monitoring, and wear monitoring help prevent costly repairs and catastrophic damage, extending equipment lifespan.

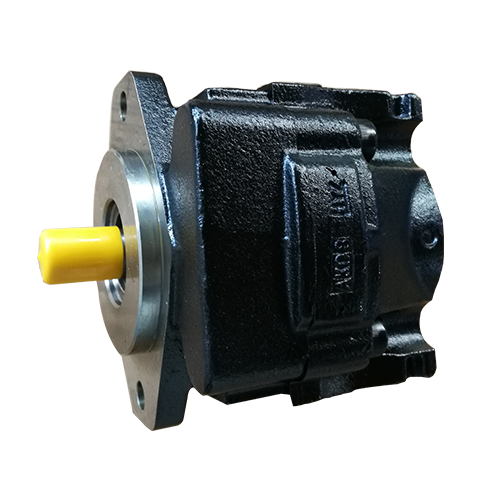

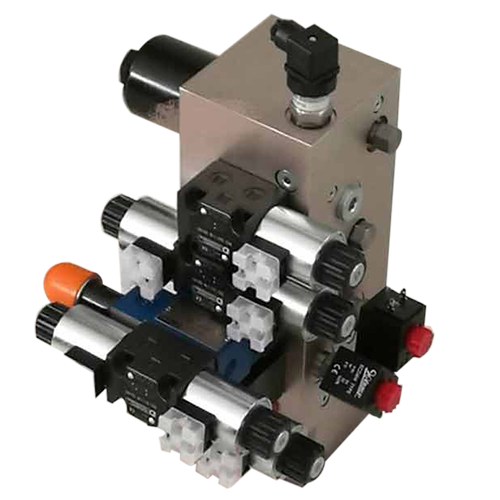

4. System Control and Fault Management: Controls for main crushing equipment, thin oil stations, hydraulic stations, cooling fans, heaters, etc., with fault warning and diagnostic functions, effectively reduce failure rates, allowing quick fault location and repair, thus lowering daily maintenance costs.

5. Discharge Port Monitoring and Adjustment: Monitoring and automatic adjustment of the discharge port improve particle shape stability and reduce rework; wear part monitoring and replacement reminders reduce unplanned downtime; IoT remote monitoring system enhances management level and decision-making efficiency.

The use of intelligent crushing equipment, as verified by multiple production lines, can improve the overall profitability of the production line.