Product Details

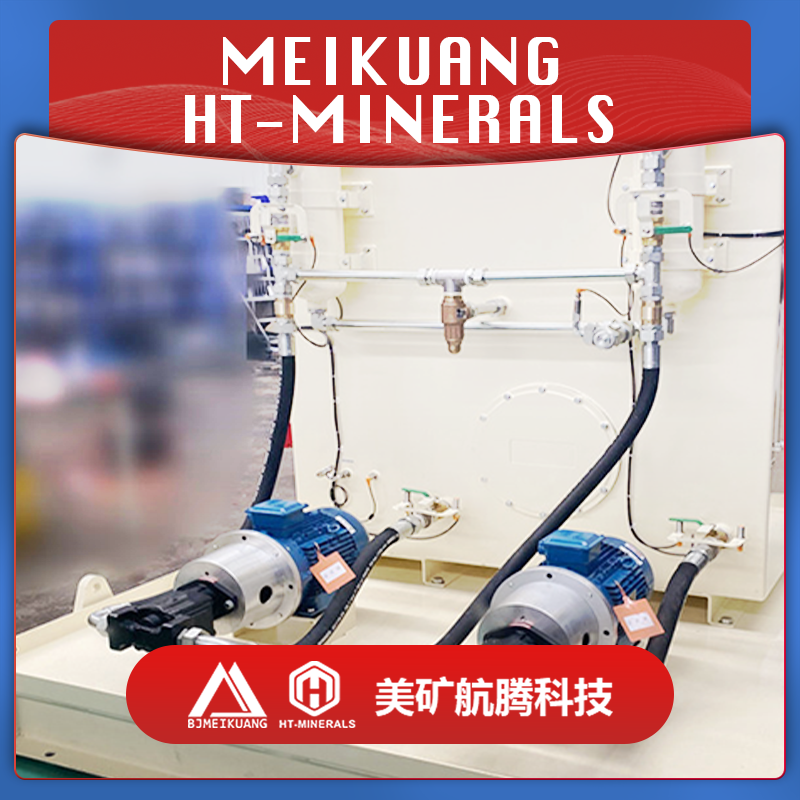

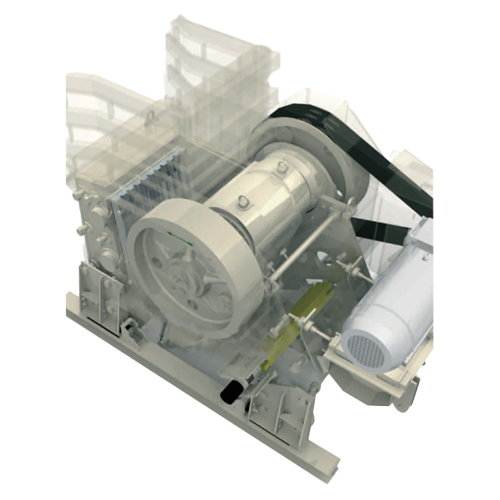

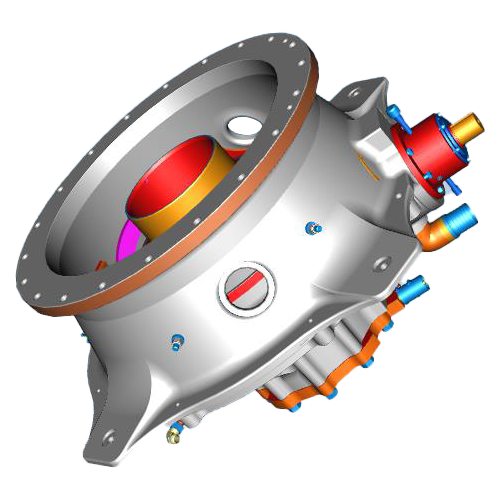

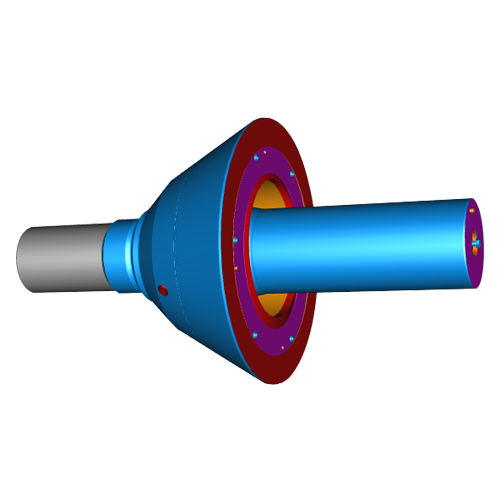

Multi-cylinder hydraulic lubrication system adopts classic foreign hydraulic lubrication control principles, integrating the pressure oil circuit and lubrication oil circuit into a highly compact unit. Utilizing high-quality international standard threaded cartridge valves in a valve island arrangement, the system has a smaller volume and a higher degree of integration. The cooling system is independently placed, providing significant cooling effects. The return oil is equipped with a magnetic filter to facilitate the removal of impurities. This system is characterized by its compact structure, quick response, and stable operation.

Applicable Main Machine Types

(HP3/4/5/6, HP100/200/300/400/500/800, MP800/1000/1250)

*All brand names, model names, photos or marks are owned by their respective manufacturers. Our company has no affiliation with the original equipment manufacturer. These terms are used for identification purposes only and are not intended to indicate affiliation with or approval by the OEM. All parts are manufactured by, for and warranted by our company and are not manufactured by, purchased from or warranted by the original equipment manufacturer.

Structural Features and Performance

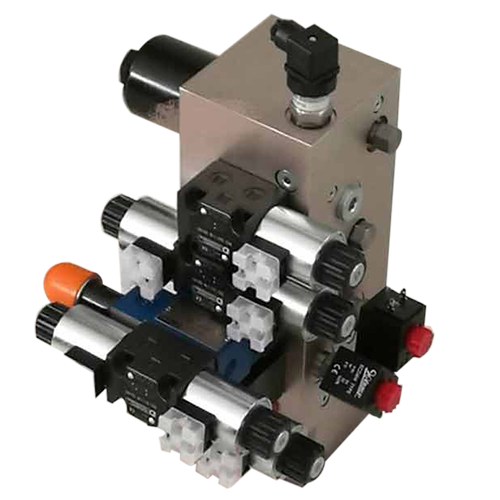

1.Hydraulic Valve: Uses a cartridge design, making the structure simpler and more compact, facilitating installation and debugging.

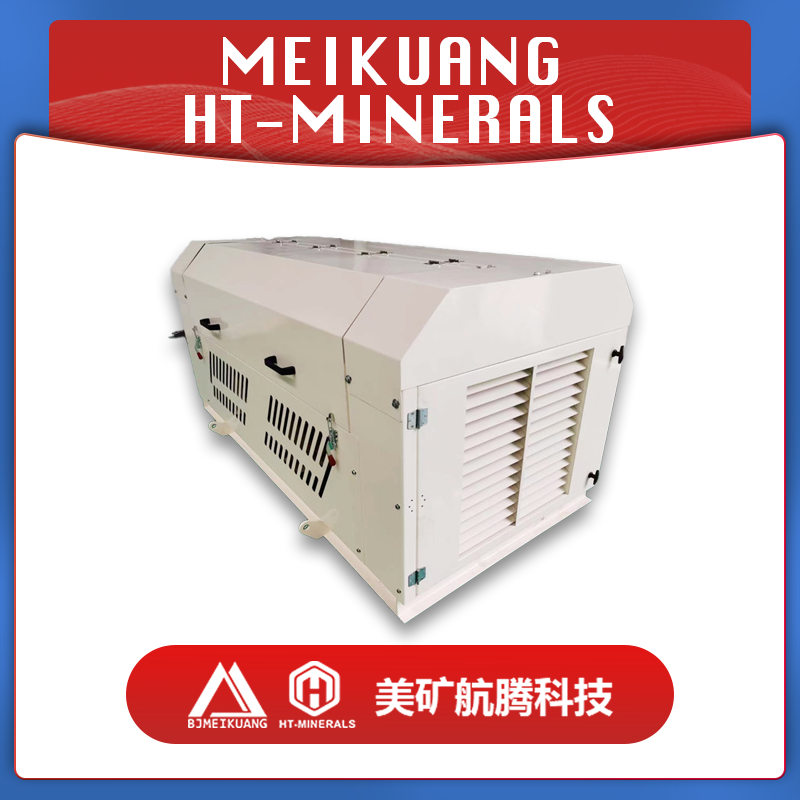

2.Cooling System: Completely upgraded air cooling system with independent placement, enhancing overall cooling capacity by 40%.

3.Hydraulic Lubrication System: Integrated layout.

4.Multiple Start-Up Methods: Available for the main machine, including soft start, auto-coupling, and variable frequency.

5.Electrical Components: Utilizes international brands and leading domestic brands, with PLC modules from Siemens.

6.Connection Between Field Box and Main Control Cabinet: Requires only one twist-pair wire (optional).

7.Operation Modes: Can switch between manual and automatic.

8.Remote Monitoring System: Allows monitoring of the machine’s operational status from any location with network access.

Product Advantages

- Higher Cost-Performance Ratio

This product is designed based on internationally renowned hydraulic stations, tailored to local conditions in China. It achieves the performance and interchangeability of imported equipment while offering a more economical and higher cost-performance design, catering to high-end customers. All interfaces perfectly match and replace the original international brand main machines and domestic main machines.

- Reduced Downtime

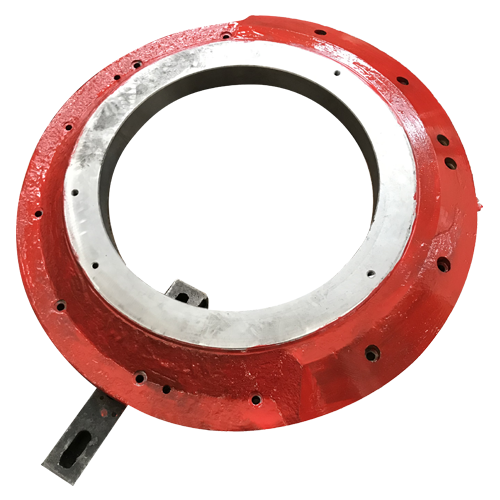

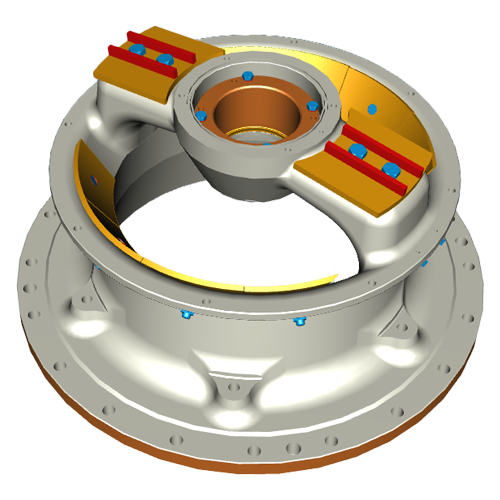

The multi-cylinder cone crusher's bidirectional iron release cylinder allows iron blocks to pass through the crushing chamber. The hydraulic chamber clearing stroke is large and unaffected by liner wear, reducing the workload required to clear clogged materials in the crushing chamber and quickly clearing the chamber. This shortens downtime and lowers the labor intensity of operators. The hydraulic motor-driven fixed cone can accurately adjust the discharge opening. Additionally, the hydraulic motor allows the fixed cone to fully retract from the adjustment ring thread, simplifying liner replacement significantly.

- Easy of Operation

A user-friendly interface and intelligent system management make it easier for operators to handle the machine. If the crusher needs to be integrated into the plant's Distributed Control System (DCS) for full automation, it only requires our self-developed ACS V3.0 automatic control system to track the discharge opening data of the crusher.

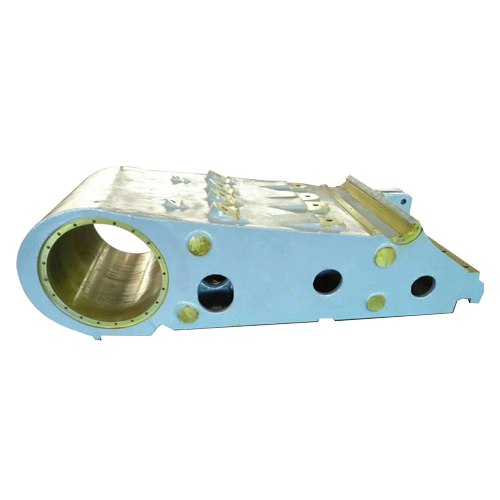

- Easy of Maintenance

The main upper cover is designed in split sections, allowing for independent removal of the sides and top for easy maintenance. This design effectively prevents dust contamination of electronic components such as solenoid valves and sensors. The large-area drawer-style return oil filter can be inspected in real-time during operation without disassembling any screws.

- High Airflow Cooling System

The newly upgraded HTM crusher-specific air cooling system increases the cooling area by 20%, airflow speed by 90%, and overall cooling capacity by 40%.

- ACS V3.0 Control System

The ACS V3.0 control system uses icons instead of text, supports multiple languages, and features a more user-friendly interface. It provides overload protection, iron protection, and automatic compensation for liner wear. By ensuring the feed is consistently full, the system maximizes the crusher's efficiency.

Basic Parameters

|

Technical Parameters |

|

|

Hydraulic Station Dimensions |

2000*900*1200 |

|

Main Lubrication Flow Rate |

130L/min @50Hz |

|

Main Lubrication Motor Power |

5.5kW |

|

Main Motor Power |

220kw/250kw |

|

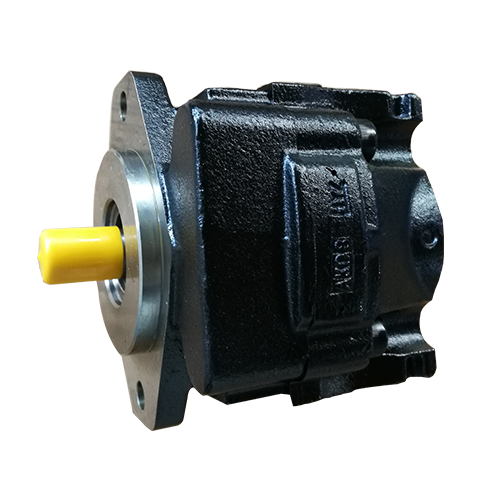

Hydraulic Pump Displacement |

14+4cc |

|

Hydraulic Motor Power |

7.5kW |

|

Heater Power |

2×6kW |

|

Type of Valve Assembly |

Solenoid Valve and Cartridge Valve Assembly |

|

Air Cooling Power |

4kW |

|

Control Cabinet |

PLC Touch Screen Intelligent Cabinet with Remote Diagnostics |

|

Starting Cabinet |

Soft Start |

Note: This diagram is for reference only. For custom requirements, please contact our company directly.