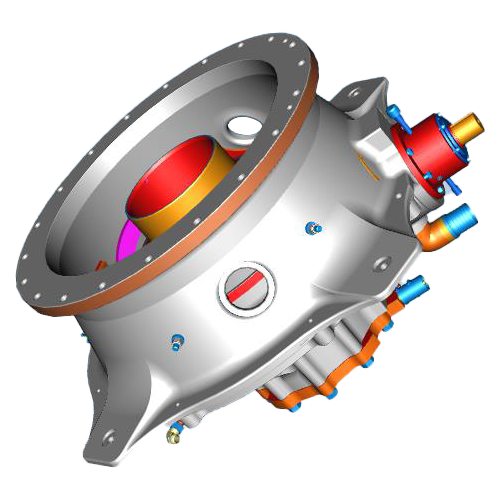

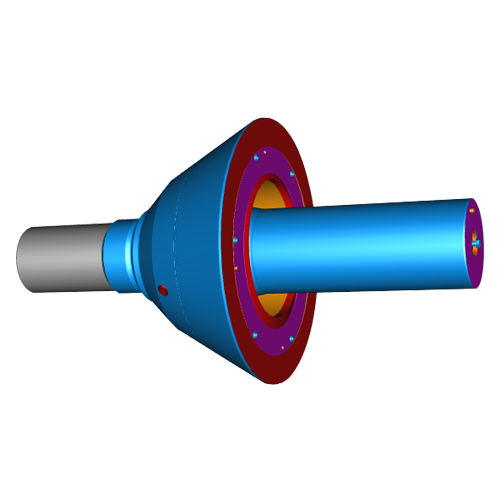

Detailed Introduction

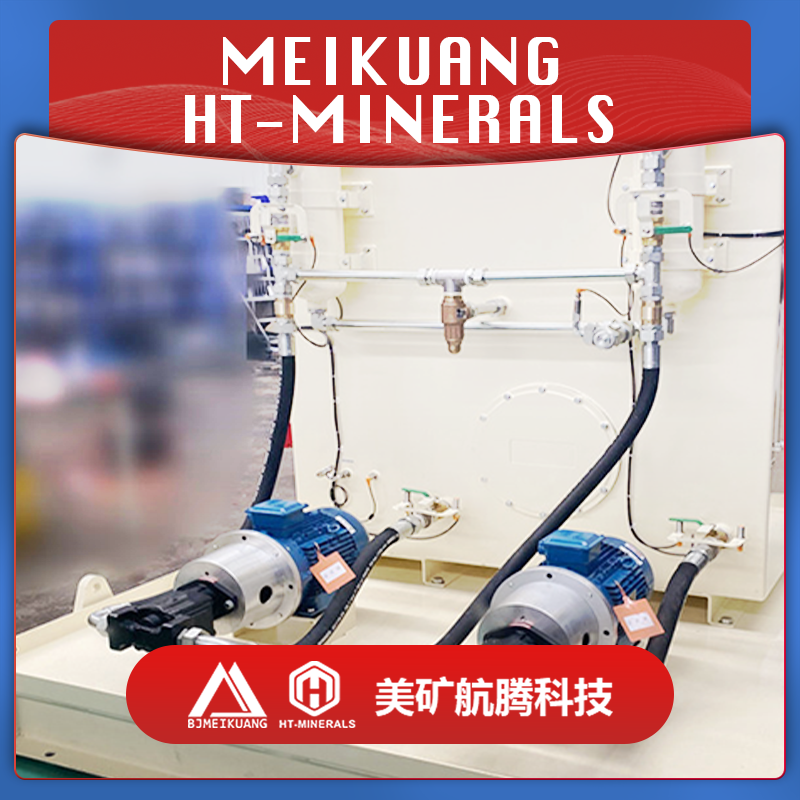

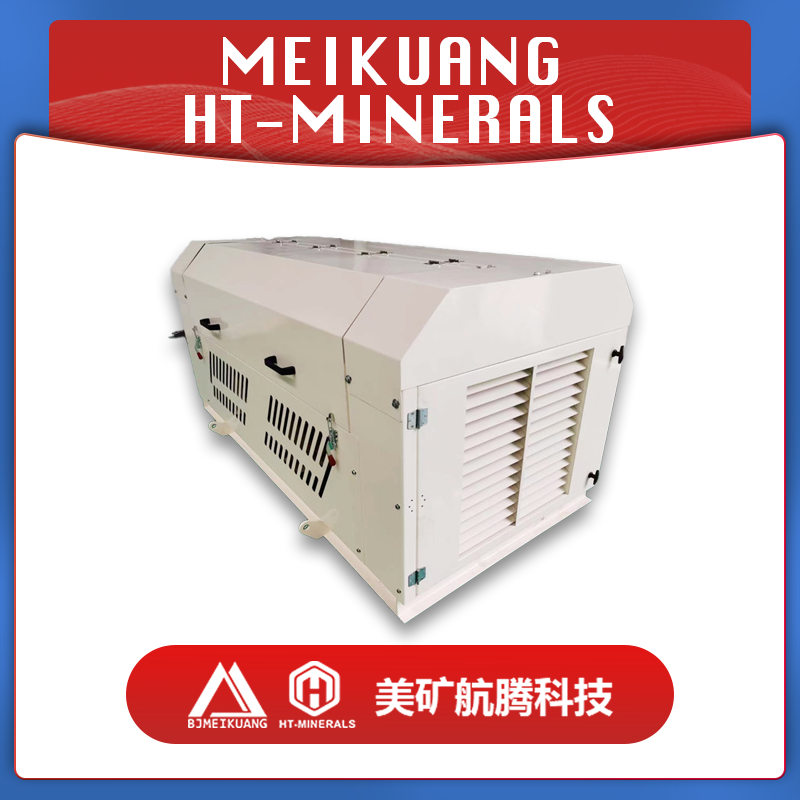

Single-cylinder hydraulic lubrication system is designed with an integrated hydraulic oil circuit and lubrication oil circuit. It also features a set of return oil filters with a mesh screen in the return oil circuit for easy inspection and maintenance. The air cooler is independently installed and equipped with a bypass valve, allowing smooth oil flow during winter.

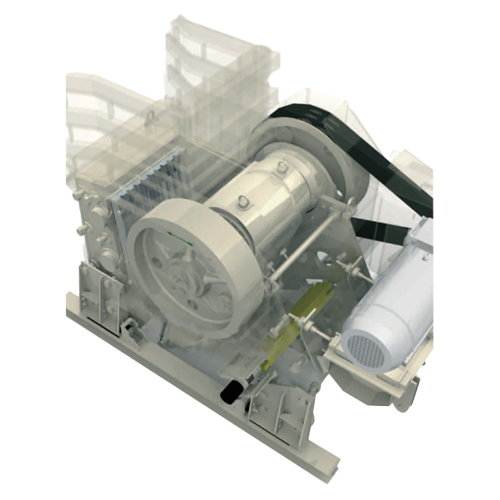

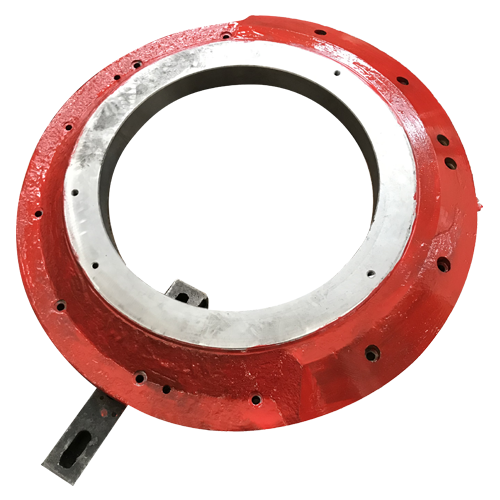

Applicable Main Machine Types

(CH420/430/CH440/660/870/890/895/GP200/220/300/330/500/550/S-type)

*All brand names, model names, photos or marks are owned by their respective manufacturers. Our company has no affiliation with the original equipment manufacturer. These terms are used for identification purposes only and are not intended to indicate affiliation with or approval by the OEM. All parts are manufactured by, for and warranted by our company and are not manufactured by, purchased from or warranted by the original equipment manufacturer.

Structural Features and Performance

Level Controller:The oil tank is equipped with a level controller that sends a low oil level alarm signal when the liquid level reaches the lower limit of the controller, interlocking the oil pump to prevent startup.

Temperature Transmitter:By detecting real-time oil temperature, the temperature transmitter sends signals to the electronic control unit to decide whether to start or stop heating or stop the main machine based on the current oil temperature.

Electric Heater:The electric heater's main role in the system is to heat the oil, controlled by the real-time detection of the temperature transmitter. This ensures smooth operation of the machinery in harsh winter conditions.

Safety Valve:Used to limit the system's operating pressure to protect internal components.

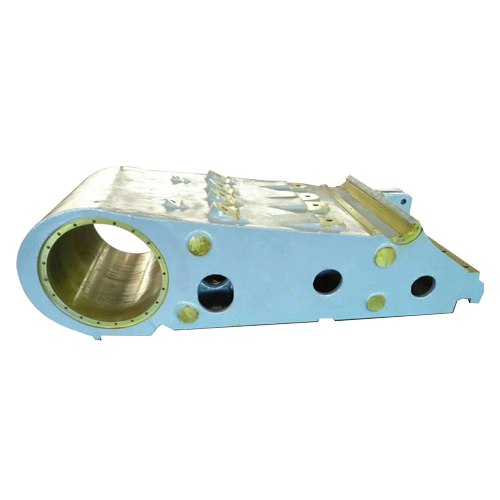

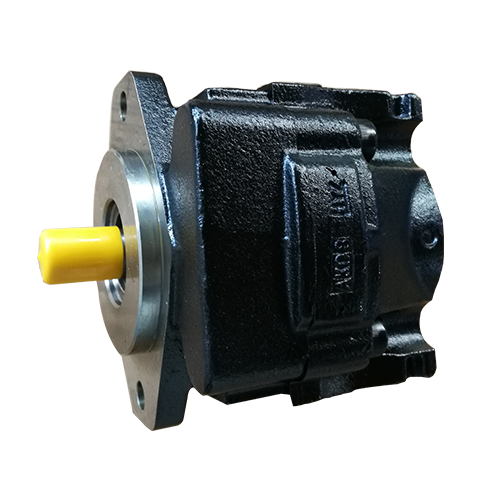

Power Unit:Comprising a bell cover, oil pump, motor, and coupling, this unit is crucial for transmitting hydraulic fluid and is one of the essential components of the entire system.

Filter:The system includes a set of filters on the oil pump's outlet pipe and a replaceable high-flow filter mesh at the end of the return pipe. The filters have clogging indicators that alert operators to clean or replace the filter element when the pressure difference increases.

Air Cooler:Primarily for cooling, the air cooler dissipates heat generated by friction surfaces during mechanical operation. Its heat dissipation capacity is determined by the heat generated by mechanical lubrication parts. The system uses an independently installed cooler with a bypass valve. During severe winter, if the oil freezes in the cooler housing, the bypass valve allows oil flow through the lubrication parts, protecting the cooler's heat sink from damage due to oil freezing.

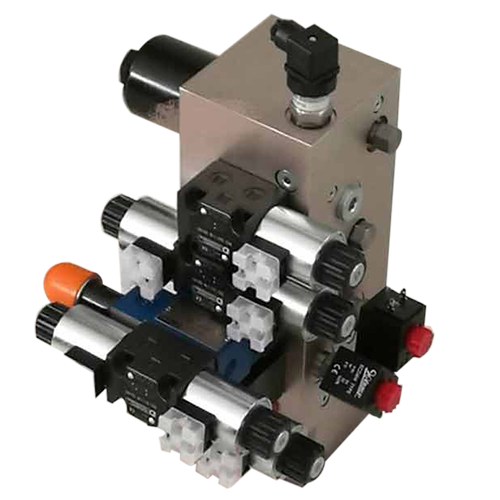

Hydraulic Valve Assembly:The core of the hydraulic system, controlling actions, pressure, and direction within the system.

Basic Parameters

|

Technical Parameters CH/S440 |

|

|

Hydraulic Station Dimensions |

2200*1100*1200 |

|

Main Lubrication Flow Rate |

73L/min @50Hz |

|

Main Lubrication Motor Power |

3kW |

|

Horizontal Shaft Flow Rate |

0.7L/min @50Hz |

|

Horizontal Shaft Motor Power |

\ |

|

Hydraulic Flow Rate |

11L/min @50Hz |

|

Hydraulic Motor Power |

3kW |

|

Heater Power |

2×6kW |

|

Valve Assembly Types |

Fully hydraulic (without solenoid valve) |

|

Air Cooling Power |

4kW |

|

Control Cabinet |

PLC touch screen intelligent cabinet with remote diagnosis |

|

Starter Cabinet |

Soft start |

|

Positive Pressure Fan |

Reserved 0.75kW electrical interface |

|

Other |

The reserved electrical interface should be noted |

|

Main Motor Power |

220kw/250kw |

Note: This image is for reference only. If customization is required, please contact our company first.