There are various types of metal ore resources in our country, but most of them are poor, miscellaneous, and fine in quality. The Lu layer high-frequency vibration fine screen is a new type of linear vibration trajectory vibration fine screen developed by our company to solve the prominent problem of high cost in the development process of domestic metal mining enterprises. It can be widely used for wet classification of fine-grained materials in mineral processing operations. Its outstanding fine-grained screening ability can significantly improve the screening efficiency, greatly reduce the amount of sand return, and thus greatly improve the production capacity and utilization rate of the mill. It solves the serious problems of low screening efficiency of old-fashioned electromagnetic vibration screens, large circulation of materials on the screen, and the serious impact on normal production caused by the overflow of fine screen feed pump pool and concentrated magnetic separation feed pump pool when the selected raw ore grade is high. The optimization of the entire beneficiation process has enabled the enterprise to further increase production and reduce consumption Improved economic efficiency.

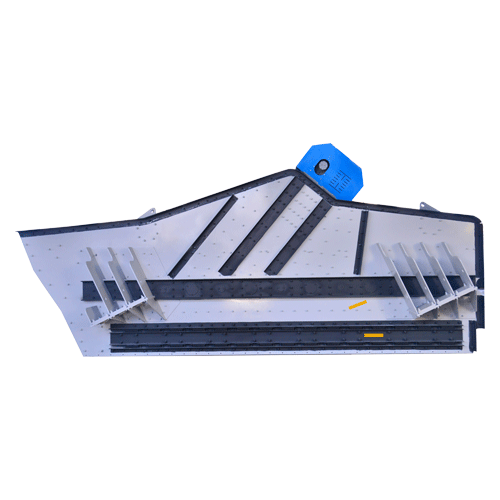

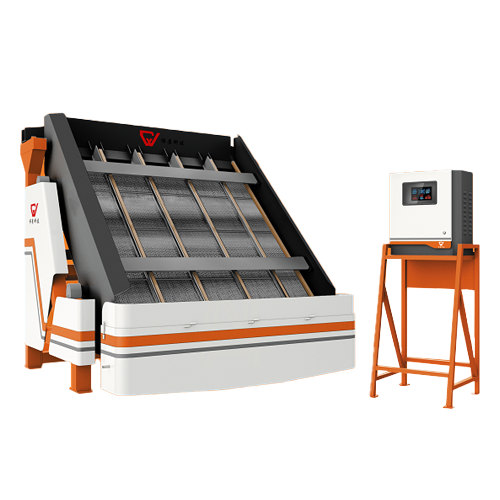

Structural schematic

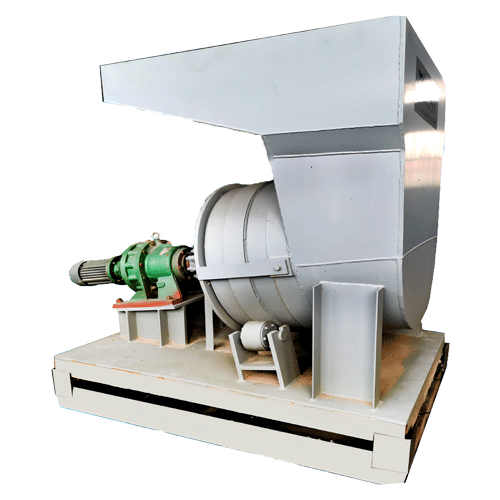

The stacked high-frequency vibration fine screen adopts a staggered stacking arrangement, that is, multiple single-layer fine screens are integrated into one machine, and each layer of screen surface independently completes the feeding and screening operations. The undersized and undersized materials on each layer of screen surface are collected and discharged separately, ensuring processing capacity while reducing ground occupation.

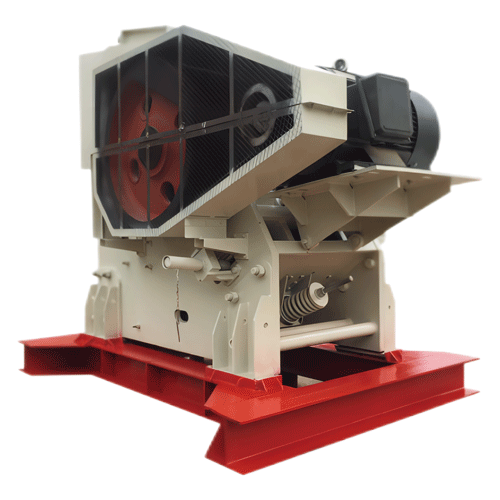

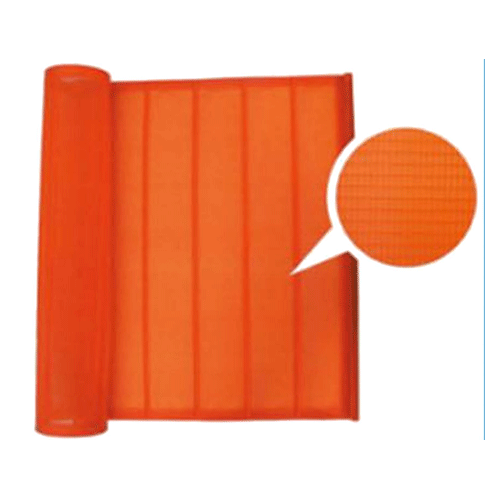

The laminated high-frequency vibration fine screen adopts the principle of linear vibration, which is generated by the high-frequency dual vibration motor rotating in opposite directions to produce linear vibration, causing the entire 5-layer sieve plate to move uniformly along the length direction of the sieve plate. High frequency and small amplitude vibration can disrupt the tension on the surface of the slurry and the adhesion of fine particles to coarse particles, resulting in loose and layered materials. The screening surface adopts polyurethane screen mesh, which has high porosity and good sieving performance, which can reduce and prevent screen hole blockage and improve screening efficiency.

Advantages and Characteristics

(1) The structure design of multi-layer screen box stacking greatly increases the screening area of the vibrating screen, which is equivalent to multiple ordinary screening machines working simultaneously, greatly improving the efficiency and processing capacity of screening.

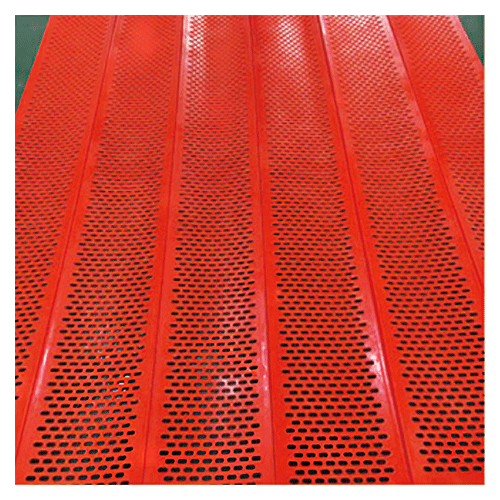

(2) Adopting high-quality, high porosity, anti clogging and wear-resistant polyurethane screen mesh, and using specialized ore separators and feeders for feeding, the material can be evenly spread on the screen surface while ensuring high production, thereby reducing the impact of slurry on the screen mesh due to excessive flow velocity and increasing the service life of the screen mesh, with an average service life of more than 6 months.

(3) Install imported vibration motors with low energy consumption, high efficiency, stable and reliable performance. The motor installation uses thread anti loosening technology, which never loosens and thoroughly ensures the reliability of the vibration source.

(4) All the slurry passing parts inside the sieve box are lined with a high wear-resistant special rubber layer, which is high-strength bonded to the surface of the box and never falls off, effectively avoiding the wear of the sieve box caused by sand flow. The exterior of the screen box is entirely coated with polyurethane spray technology, with a spray thickness of 2-3mm, greatly improving the wear and corrosion resistance of the screen box. The screen box plate is made of low-alloy high-strength structural steel, and the production adopts CNC cutting technology. The overall heat treatment of the screen box eliminates stress, completely avoiding secondary deformation of the screen box and effectively extending the service life of the equipment.

(5) Multiple parallel connections, occupying a small space. The five screen frames of the vibrating screen are in the form of stacked layers, which is equivalent to merging the footprint of five screening machines into one screening machine, making the entire vibrating screen appear more compact and increasing the flexibility of installation on the production site.

Technical Parameter

|

Power |

1.84kW*2 |

|

Screen Specifications |

1240*840mm |

|

Hole Fraction |

31%-45% |

|

Sieve Hole Specifications |

0.075-0.6mm(其它尺寸可定制) |

|

Amplitude |

1.33-2.61mm |

|

Motor speed |

1500RPM |

|

Cape |

20° |

|

Feed density |

30%-40% |

|

Max screening efficiency |

≥90% |

|

Power supply |

AC380V,50Hz |