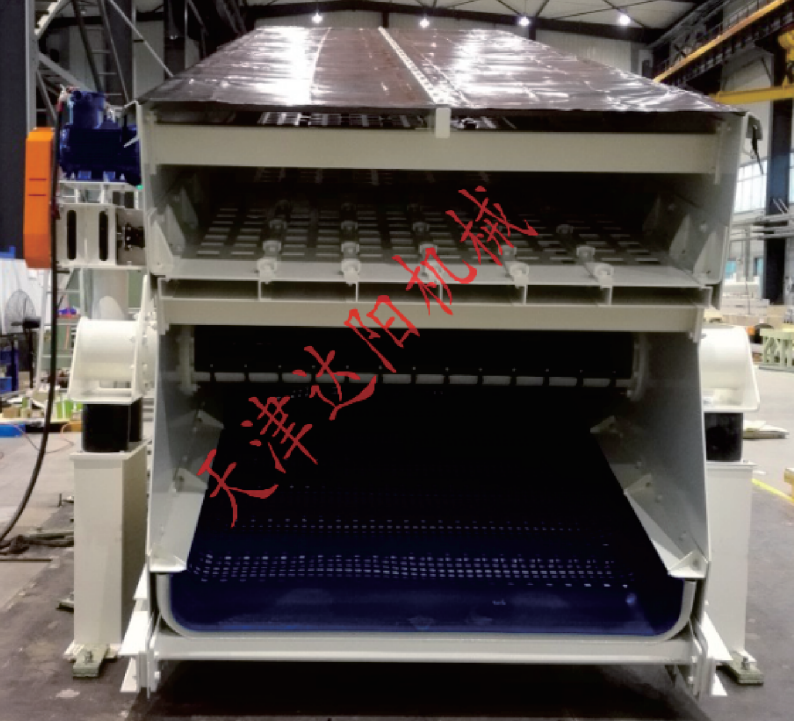

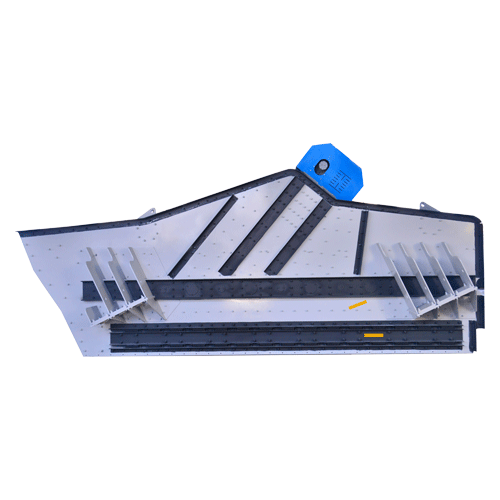

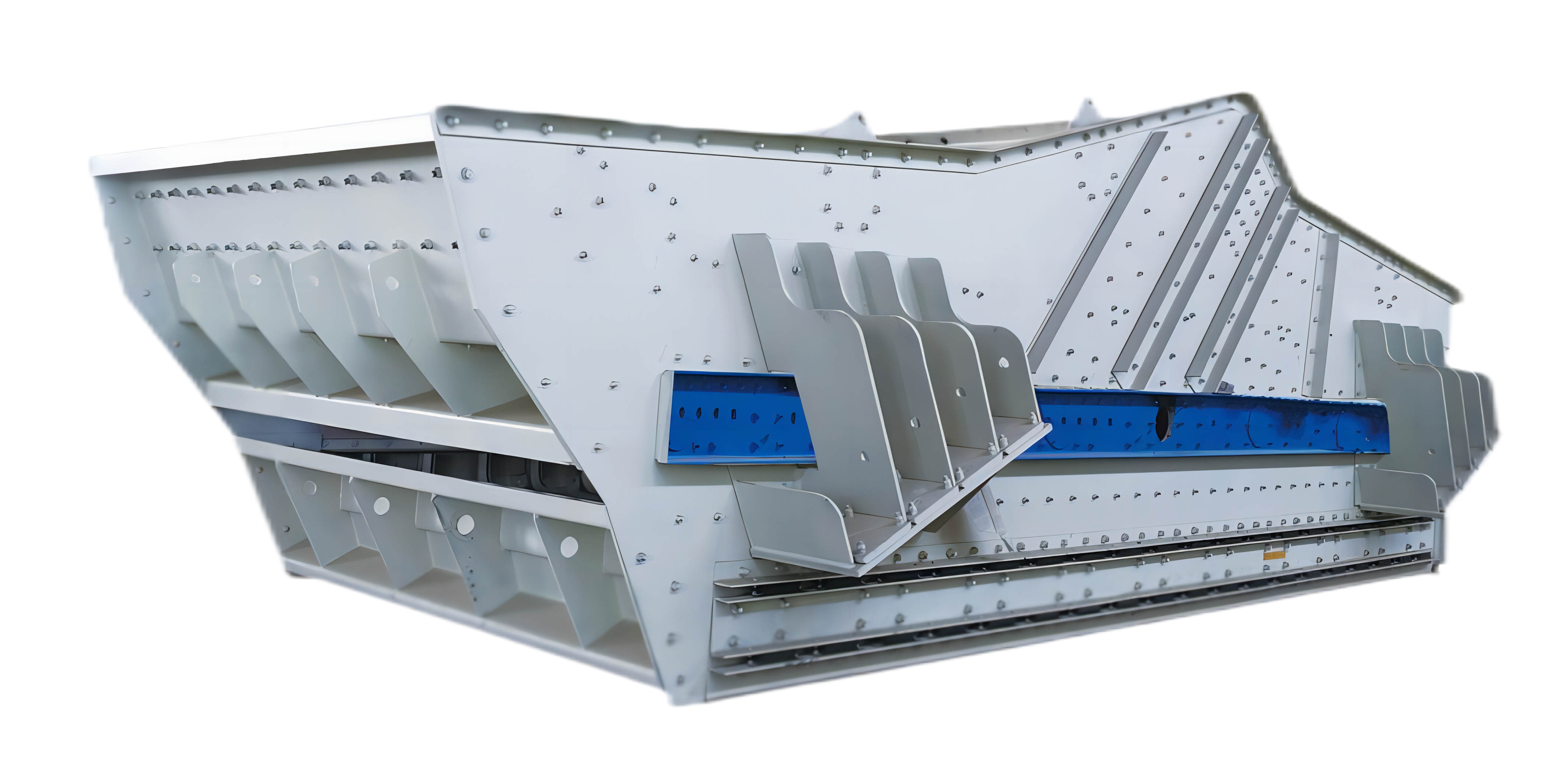

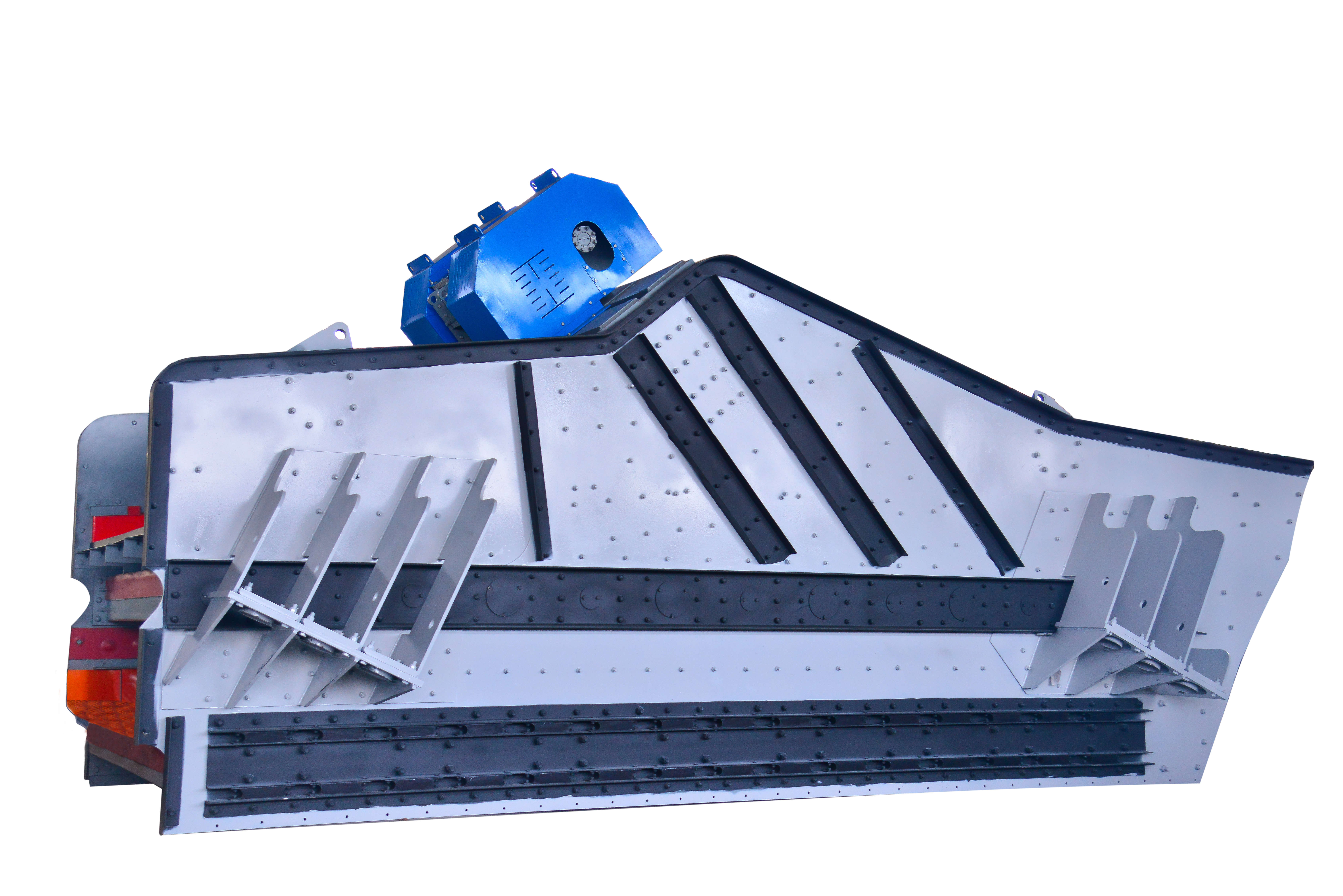

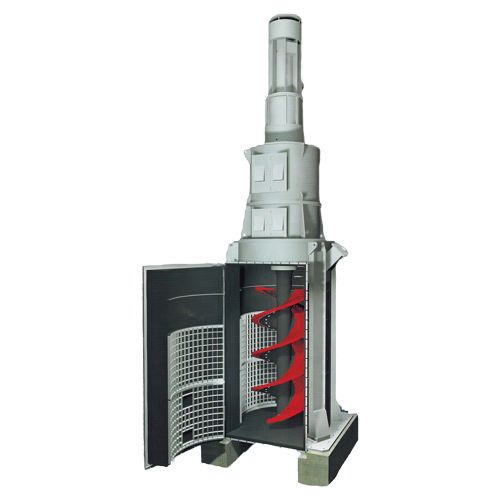

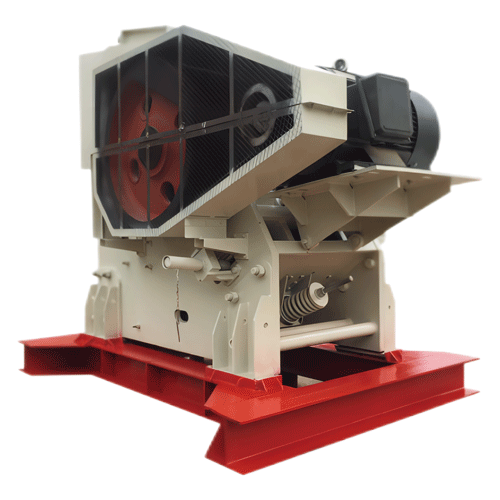

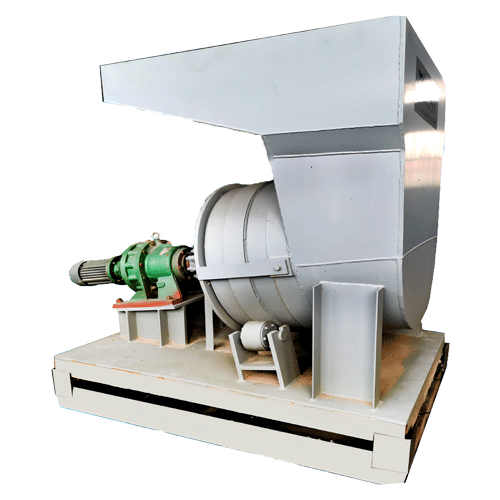

The heavy-duty micro powder sieve surface is composed of a fixed frame, a floating frame, and sieve plates. The floating frame, driven by additional vibration, performs reciprocating motion to expand and contract the sieve plates, causing them to continuously deform and preventing materials from clogging the sieve holes. Compared to ordinary sieves, it effectively increases the screening area and improves screening efficiency.

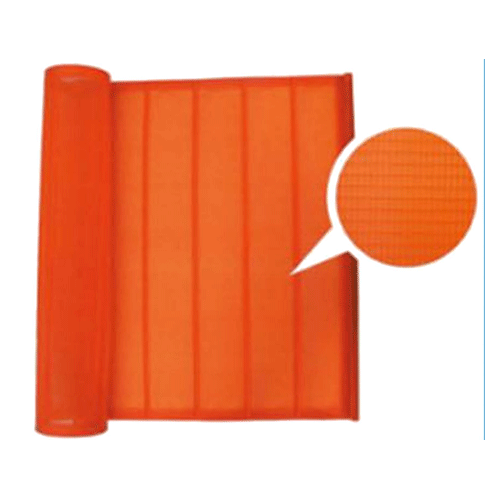

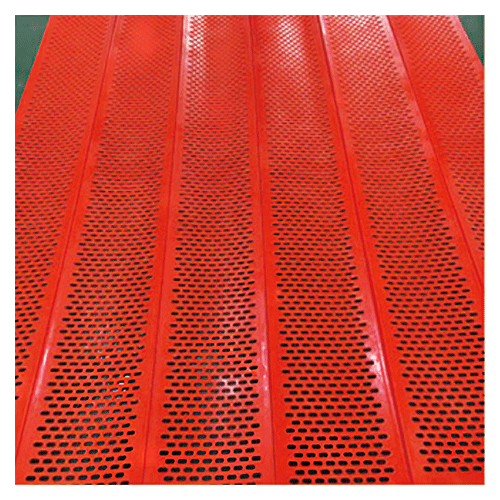

The structural design of heavy-duty micro powder screening polyurethane screen plate reflects the characteristics of good wear resistance, elasticity, high elongation at break, and resistance to bending of polyurethane elastomer. This screen plate is suitable for screening wet materials and has the characteristics of high screening efficiency, long service life, wide particle size range, no blockage, and no adhesion. The heavy-duty micro powder sieve plate is widely used for product grading in industries such as coal mining, coke, mining, building materials, transportation, energy, and chemical engineering. It is an ideal sieve plate for heavy-duty micro powder sieve grading equipment and has high screening efficiency, suitable for screening wet materials.

Superiority

Compared with ordinary vibrating screens, heavy-duty micro powder screens generate double vibration through exciters, and have a unique active beam design combined with elastic polyurethane screen plates. During the working process, the sieve and floating beam move back and forth together, so there will be no material blockage. It can screen materials with fine particle size, high viscosity, and high humidity (such as coal, coke, and ore with high viscosity and high moisture content).

The unique feature of heavy-duty micro powder screening lies in the dual vibration generated by one drive, a basic vibration (exciter and fixed frame) and an additional vibration (floating screen frame). In this process, the floating beam performs reciprocating motion under the traction of rubber springs on both sides, and the elastic polyurethane screen surface continuously expands and contracts (700~800 times per minute) to obtain a high acceleration (50G), preventing screen hole blockage and effectively improving screening efficiency.

Technical Parameter

|

Specification And Model |

HXCX-1860 |

HXCX-2460 |

HXCX-3080 |

HXCX-42100 |

||

|

Number of Screening Layers |

|

2 |

3 |

2 |

2 |

2 |

|

Screening Area |

m² |

21.6 |

32.4 |

28.8 |

48 |

84 |

|

Mesh size |

Upper sieve plate |

20mm/16mm/13mm/10mm |

20mm/16mm/13mm/10mm |

20mm/16mm/13mm/10mm |

20mm/16mm/13mm/10mm |

|

|

Lower layer sieve |

2/3/4/5/6/8mm |

2/3/4/5/6/8mm |

2/3/4/5/6/8mm |

2/3/4/5/6/8mm |

||

|

Operating Frequency |

Hz |

13.3HZ-15HZ |

13.3HZ-15HZ |

13.3HZ-15HZ |

13.3HZ-15HZ |

|

|

Output Speed |

RPM |

850RPM-1050RPM |

850RPM-1050RPM |

850RPM-1050RPM |

850RPM-1050RPM |

|

|

Power |

kW |

37KW 1480RPM/4-pole,380V,50HZ |

50KW 1480RPM/4-pole,380V,50HZ |

55KW 1480RPM/4-pole,380V,50HZ |

90KW 1480RPM/4-pole,380V,50HZ |

|

|

Work Amplitude |

mm |

7mm-12mm |

7mm-12mm |

7mm-12mm |

7mm-12mm |

|

|

Feed Particle Size |

≤ |

30mm |

30mm |

30mm |

30mm |

|

|

Processing Capacity |

T/h |

350-600 |

450-800 |

800-1200 |

1200-1800 |

|

|

Material Density |

kg/m3 |

≥2300Kg/m3 |

≥2300Kg/m3 |

≥2300Kg/m3 |

≥2300Kg/m3 |

|

|

Moisture Content |

≤ |

8% |

8% |

8% |

8% |

|

|

Screen Surface Form |

|

Polyurethane wire mesh trawl polyurethane screens |

Polyurethane wire mesh trawl polyurethane screens |

Polyurethane wire mesh trawl polyurethane screens |

Polyurethane wire mesh trawl polyurethane screens |

|

|

Damping system |

|

Steel spiral spring |

Steel spiral spring |

Steel spiral spring |

Steel spiral spring |

|

|

Inclination of sieve |

° |

25° |

25° |

25° |

25° |

|

|

Number of exciter models |

ML80 |

1 |

2 |

2 |

3 |

|

|

Weight (approximately) |

T |

24 |

31 |

30 |

35 |

65 |

DCZ弛张筛系列产品_副本.png)