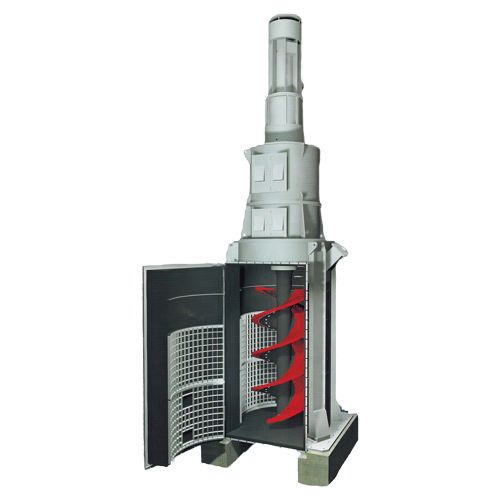

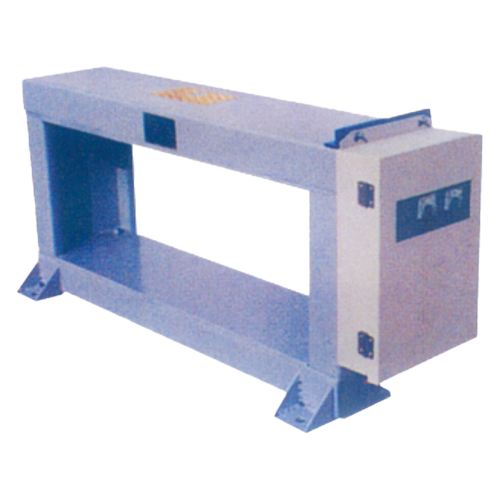

The intelligent iron remover consists of a metal detector, an intelligent control system, and an iron stone separator. The intelligent iron remover is installed at the top of the conveyor belt transporting the crushed material to the next crusher. When metal blocks (including non-magnetic metal blocks) mixed in the transported materials pass through the metal detector, the detector can promptly emit sound and light alarm signals to the intelligent control system. The system will issue instructions to the iron stone separator at a specified time to separate the iron from the stone and ensure the safe operation of the next crusher.

Widely used in metallurgy, mining, coal preparation plants, power plants, ceramics, glass, cement, building materials, chemical, food and feed processing industries. In the emerging waste treatment industry, iron removers are also needed to recover steel from waste. Iron removers have been used in various large steel enterprises, as well as metal mines, power plants, light industry, refractory materials and other industries, and have played a huge role.

Characteristic

1. Adopting a fully sealed structure with good moisture resistance.

2. Through computer optimization design, it has a reasonable structure, light weight, low energy consumption, and long service life.

3. The rated power continuity rate of ordinary electromagnets has been increased from 50% in the past to 60%, which has improved the efficiency of electromagnet use.

4. By adopting a unique detection method, it is not affected by material temperature and expands the applicability of the iron remover.

5. Easy to install, operate, and maintain.

Technical Parameter

|

Model and Parameter List |

||||

|

Model |

Adaptive Bandwidth(mm) |

Material Thickness (≤mm) |

Drive Power(kW) |

Adapt To Belt Speed (≤m/s) |

|

SC series |

Customizable on demand |

800 |

4.4 |

10 |

|

Main technical parameters of RCDD electromagnetic self dumping iron remover |

||||||||||||

|

Model |

Adapt to bandwidth (mm) |

Rated lifting height (mm) |

magnetic field intensity (≥MT) |

Material thickness (≤mm) |

Excitation power (≤KW) |

Drive power (≤KW) |

Adapt to belt speed (≤m/s) |

外型尺寸mm Dimensions(mm) |

||||

|

A |

B |

C |

D |

E |

||||||||

|

RCDD-5 |

500 |

150 |

60 |

100 |

1 |

1.5 |

2.5 |

2020 |

1040 |

775 |

853 |

1000 |

|

RCDD-6 |

600 |

175 |

60 |

130 |

1.8 |

1.5 |

2140 |

1100 |

800 |

910 |

1100 |

|

|

RCDD-6.5 |

650 |

200 |

70 |

150 |

2 |

2.2 |

2275 |

1190 |

820 |

988 |

1250 |

|

|

RCDD-8 |

800 |

250 |

70 |

200 |

3 |

2.2 |

2540 |

1480 |

865 |

1287 |

1350 |

|

|

RCDD-10 |

1000 |

300 |

70 |

250 |

4.5 |

3 |

2750 |

1635 |

940 |

1420 |

1400 |

|

|

RCDD-12 |

1200 |

350 |

70 |

300 |

5.8 |

3000 |

1800 |

1010 |

1580 |

1700 |

||

|

RCDD-14 |

1400 |

400 |

70 |

350 |

6.7 |

4 |

3500 |

2050 |

1050 |

1800 |

2000 |

|

|

RCDD-16 |

1600 |

450 |

70 |

400 |

9.5 |

5.5 |

3900 |

2450 |

1180 |

2200 |

2350 |

|

|

RCDD-18 |

1800 |

500 |

70 |

400 |

12.5 |

7.5 |

4400 |

2850 |

1290 |

2600 |

2800 |

|

Power: The power of a suspended electromagnetic iron remover is usually measured in kilowatts (kW).

Outer diameter size: The outer diameter size of a suspended electromagnetic iron remover refers to the diameter or length outside its device.

Hanging height: This refers to the height of the suspended electromagnetic iron remover above the ground.

Iron ore processing capability.

Suspension current: This refers to the current required for a suspended electromagnetic iron remover.