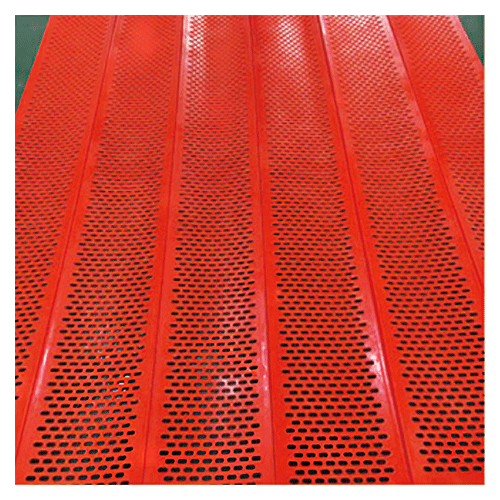

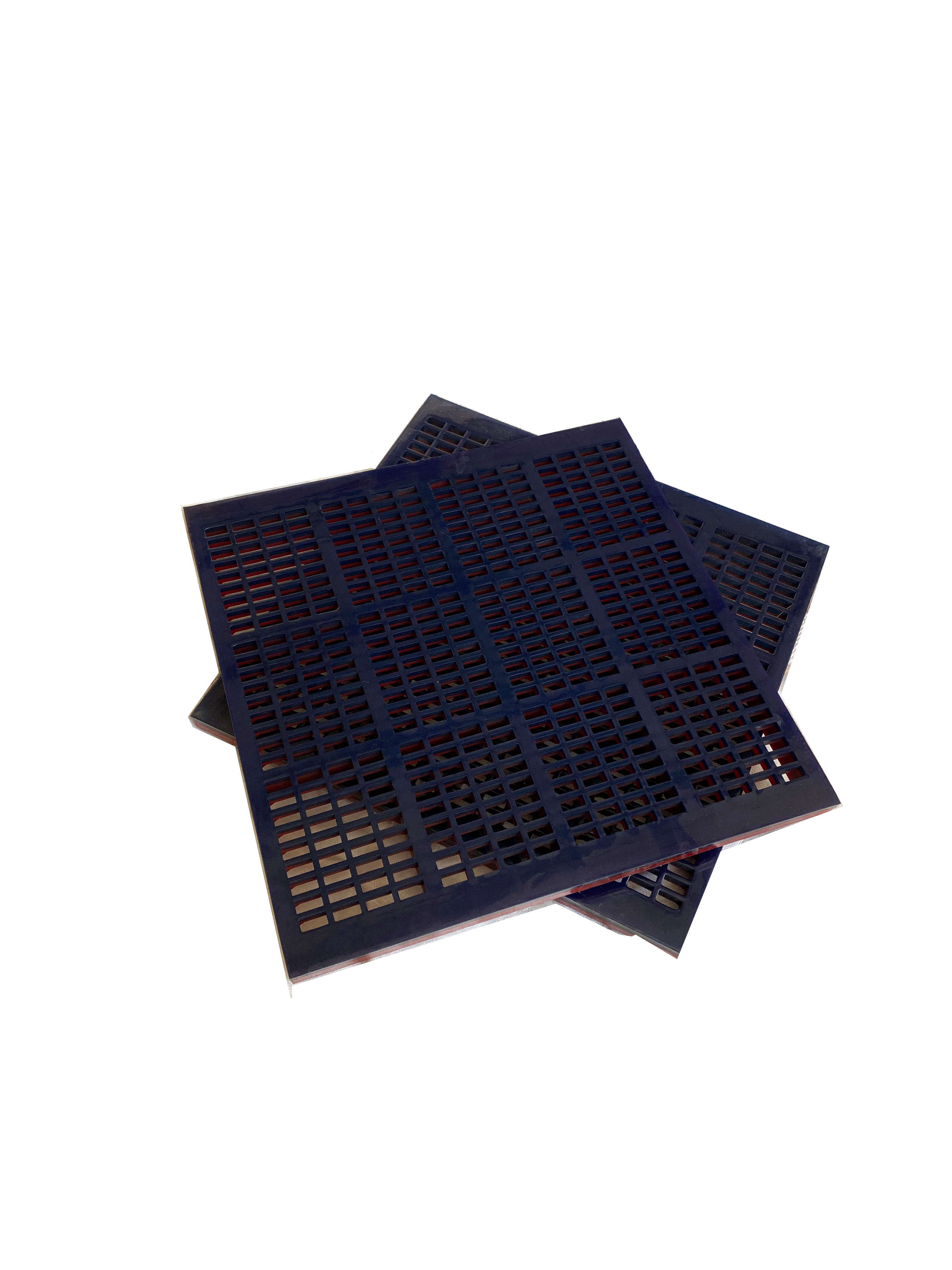

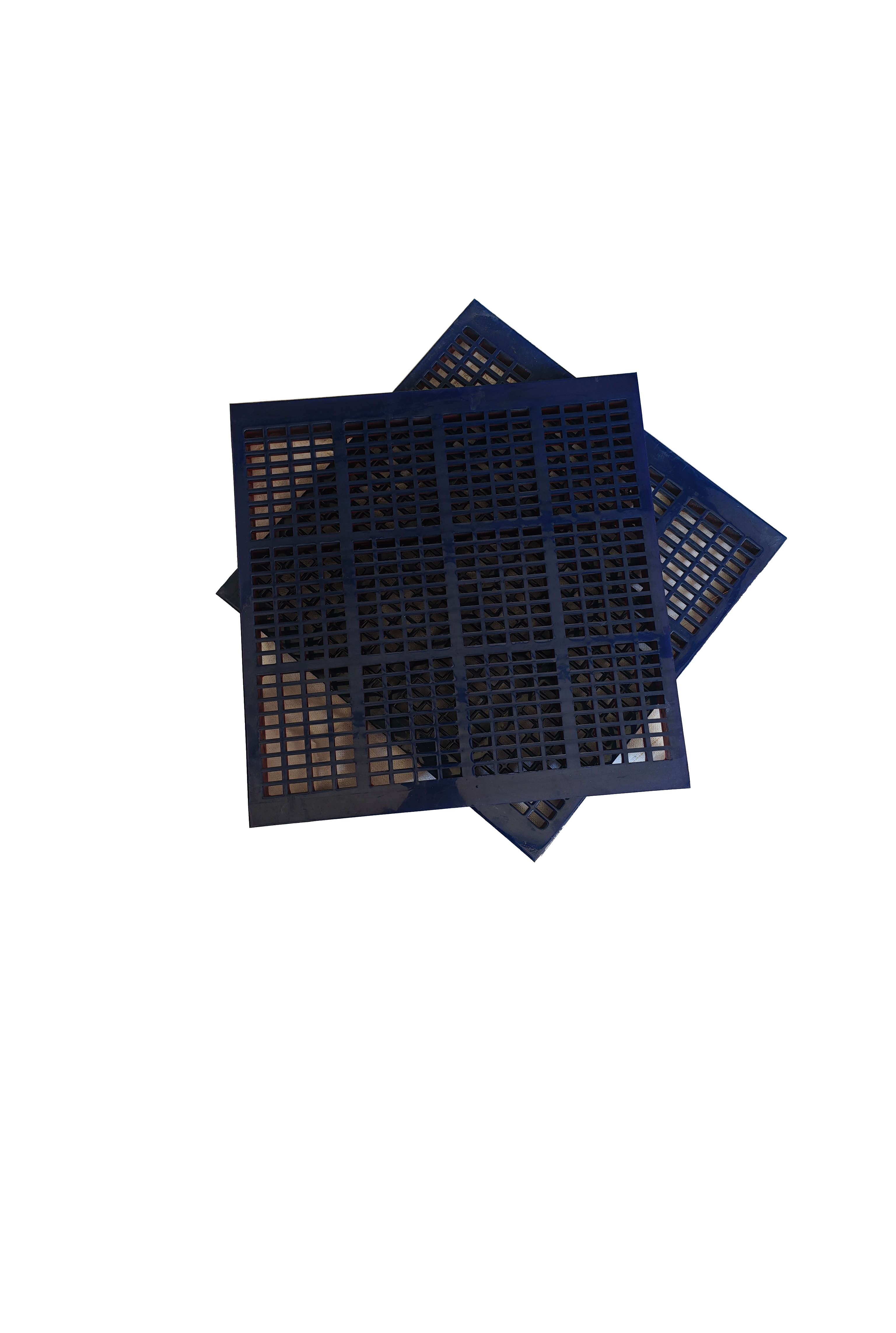

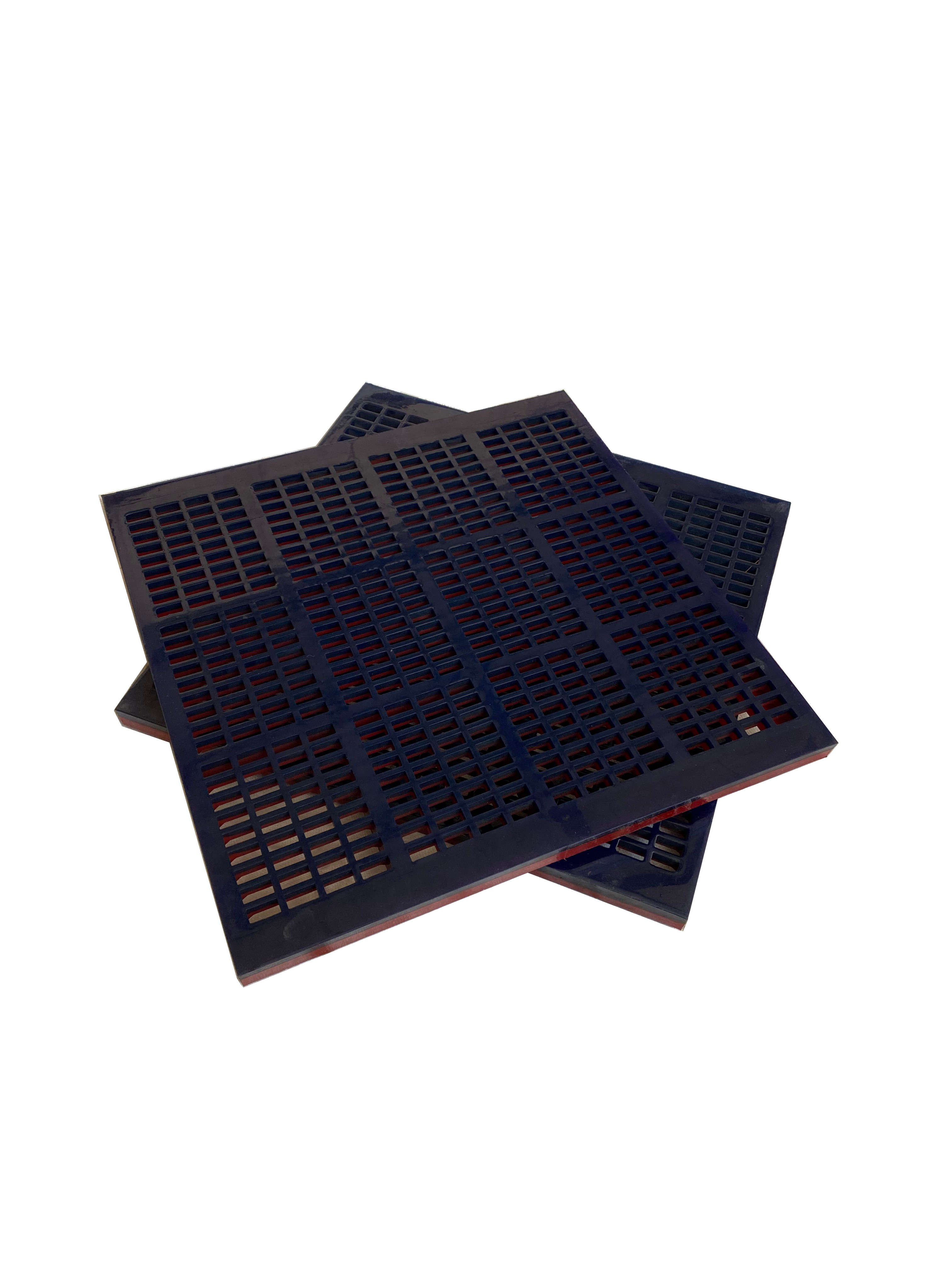

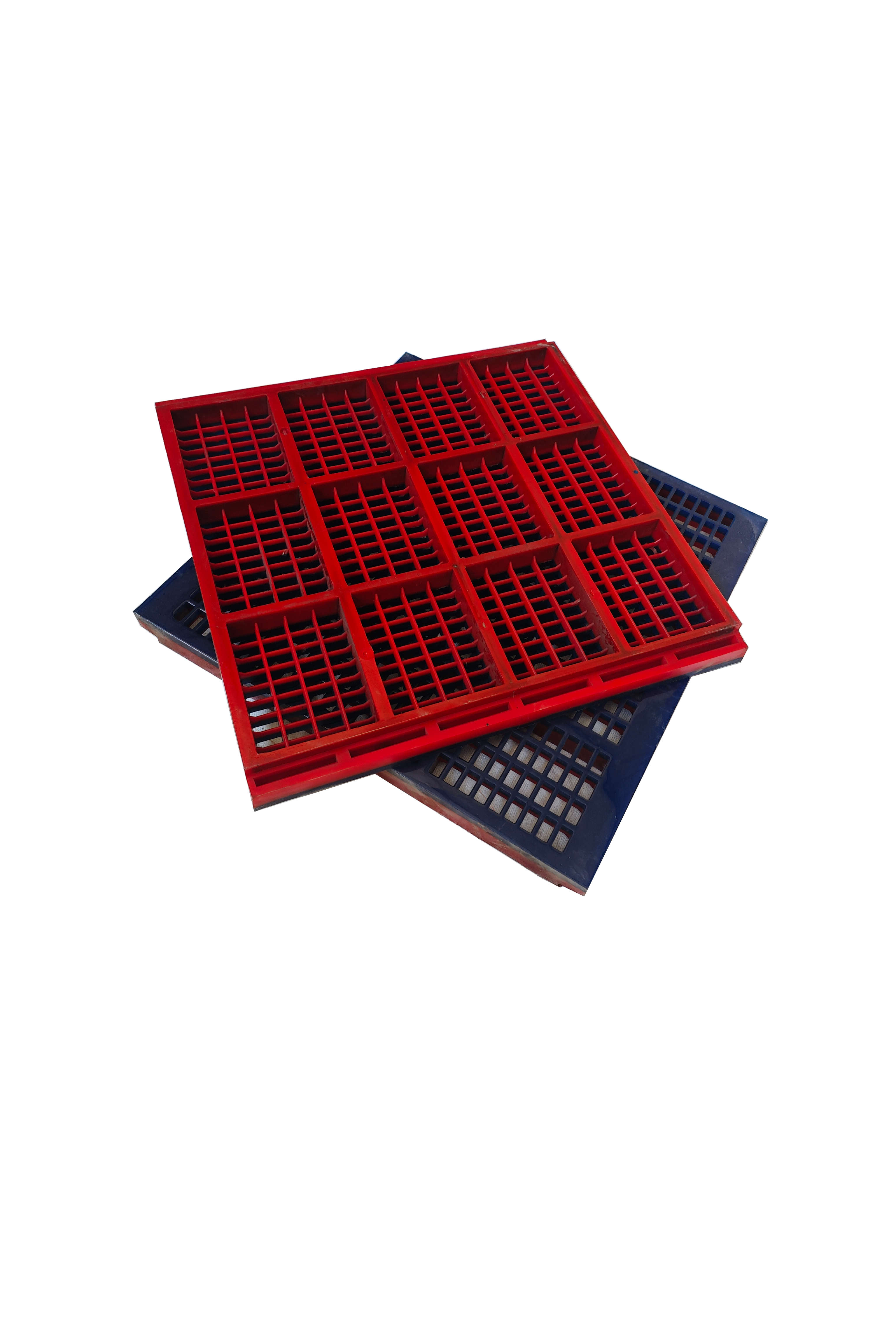

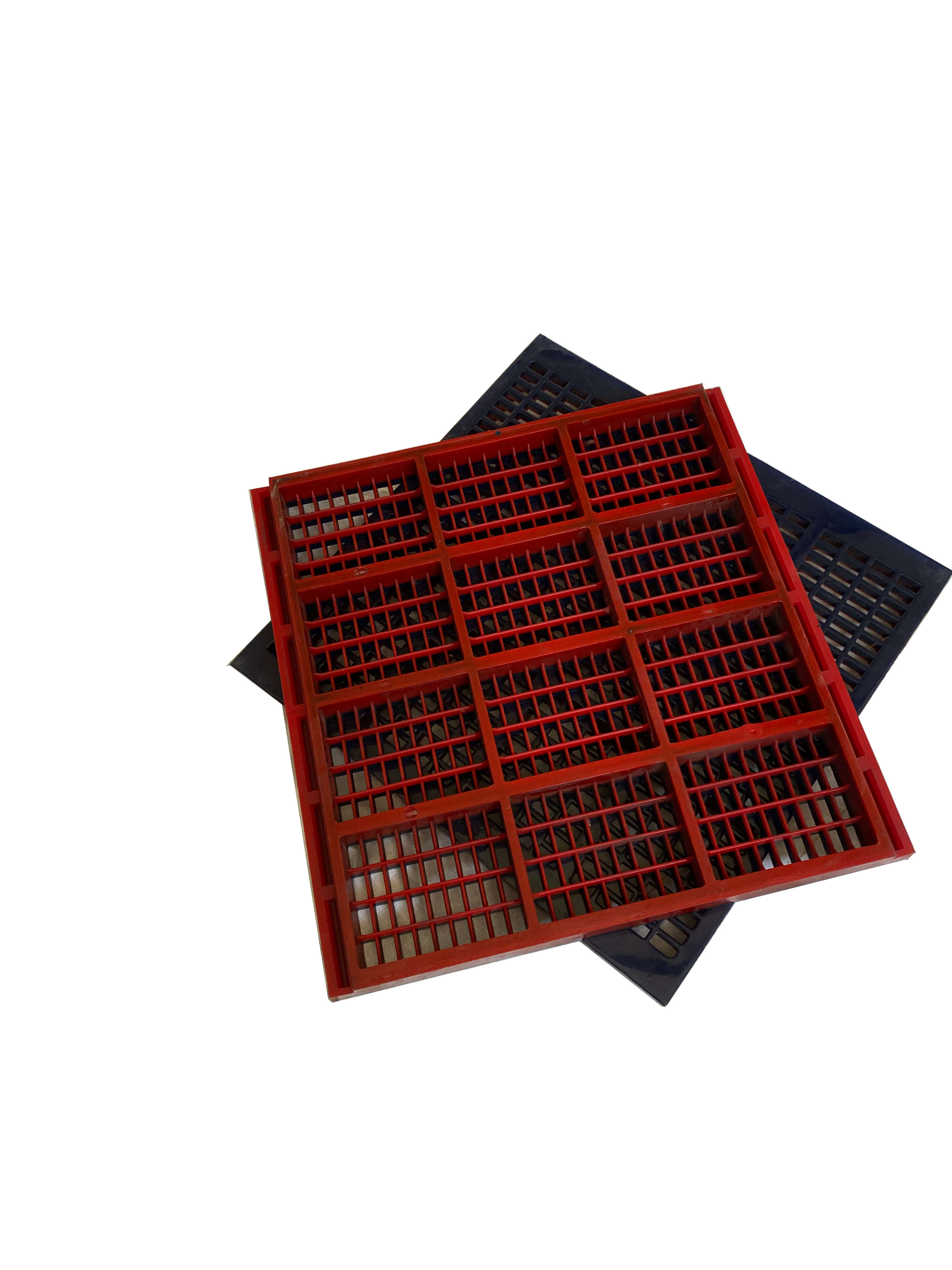

The polyurethane relaxation screen mesh is used on the relaxation screen, with one end fixed on a fixed crossbeam and the other end fixed on a floating crossbeam. The relative motion between the fixed beam and the floating beam causes the screen mesh to continuously expand and contract, transmitting very high acceleration to the material, thereby allowing the material to be fully lifted and layered. The mesh of the relaxation screen can transmit an acceleration of up to 50g to the material, allowing it to fully loosen and pass through the screen, completing the screening process. During the screening process, the screen undergoes elastic deformation due to continuous bending motion, which throws wet and viscous materials away from the screen surface and has self-cleaning function, greatly improving the processing capacity and screening efficiency of the screening machine. Relaxation screening is widely used in dry screening operations for difficult to screen materials such as medium to fine particles, wet and viscous materials.

Characteristic

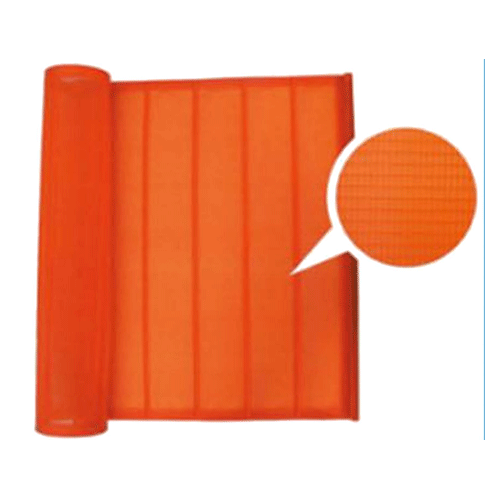

1. The screen surface is thin, with good wear resistance, elasticity, high elongation at break, and resistance to bending. It has a high porosity, larger processing capacity, and higher screening efficiency

2. The relaxation screen adopts a special process structure inside, which can withstand a vibration force of 50G, effectively extending the service life of the screen plate. It has the advantages of high screening efficiency, no blockage, and no adhesion.

3. The relaxation screen adopts an embedded installation method and a bolt free connection horn shaped installation groove, which is very convenient for disassembly and assembly, effectively reducing customer maintenance costs and labor intensity.

Technical Parameter

|

Relaxation sieve plate size (W) mm |

Relaxation sieve plate size (L) mm |

Width of screen mesh(mm) |

Porosity of screen mesh(%) |

|

610 |

610 |

20 |

35-45% |

|

16 |

|||

|

13 |

|||

|

10 |

|||

|

Relaxation sieve plate size (W) mm |

Relaxation sieve plate size (L) mm |

Width of screen mesh(mm) |

Porosity of screen mesh(%) |

|

363 |

3210 |

8 |

20-30% |

|

6 |

|||

|

5 |

|||

|

4 |

|||

|

3 |

|||

|

2 |

|||

|

Note: The length of the screening machine varies depending on the model. The data in the table is for selection reference only. The actual situation should be determined based on the properties of the processed materials and the required product particle size or industrial testing. At the same time, according to user needs, products of models not listed in the table can be provided for more flexible and practical selection. |

|||

微信截图_20220624093915.png)

微信截图_20220624092614.png)

微信截图_20220624091317.png)

微信截图_20220624090751.png)

微信截图_20220624085326.png)