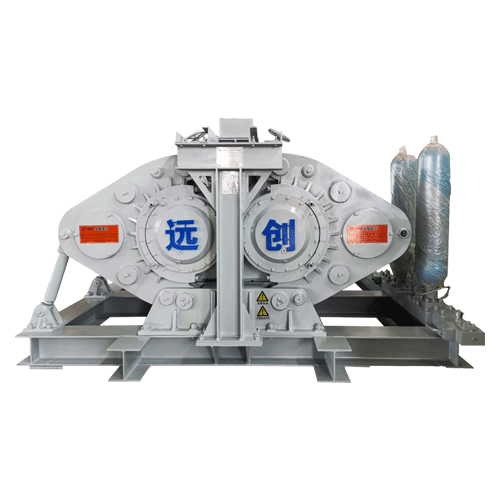

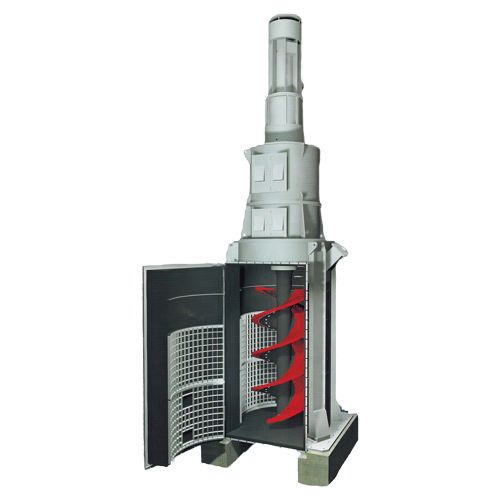

Used for automatic replenishment of steel balls during the grinding process of ball mills, it has the function of improving the efficiency of ball mills, reducing electricity and water consumption. Effectively overcoming the drawbacks of other ball adding machines in the current market, such as easy ball jamming, clogged ball outlets, and inability to add small balls. After more than ten years of on-site use and improvement, the product's performance is stable and reliable, and has been widely recognized by users. To meet the need of adding two or more diameter steel balls to the factory's ball mill at the same time, the company has specially developed a new type of double ball adding machine. It can add two types of steel balls at the same time, with two sets of execution systems and two separate ball chambers for counting. Adding steel balls separately is suitable for advantages such as large ball quantities and multiple ball specifications. This machine consists of a drive device, an actuator, a ball compartment, and a control unit. The actuator is composed of a reducer sprocket chain and ball claws on the chain. The control device is composed of a microcomputer and an operation control box, which can automatically add balls under the set time and quantity conditions, and can set the cumulative and display amount of balls within the set range. At the same time, it can achieve ball free and fault alarm shutdown. The ball adding machine can switch between manual and automatic operation.

Characteristic

1. It is suitable for various steel balls with different diameters, such as non capped balls, non stuck balls, and more;

2. It has functions such as timed, quantitative, uniform addition of balls, cumulative addition of balls, and no ball alarm;

3. By maintaining a reasonable ball to load ratio in the ball mill, the grinding efficiency can be improved;

4. Reduce ball and electricity consumption, alleviate labor intensity for workers, and importantly, compensate for the shortcomings of manual one-time ball addition.