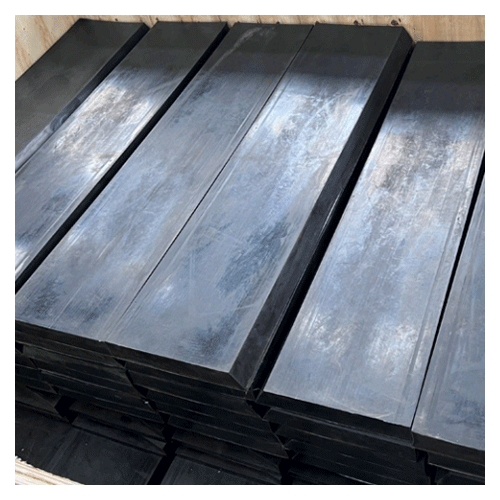

Rubber screen plates can ensure that the entire screen surface is free from blockages and material accumulation, reduce noise, and provide excellent wear resistance, thereby maintaining efficient screening, saving costs, and improving efficiency.

The shape, size, thickness, and fixing method of the rubber sieve plate of Stoddais are constantly improving. We have the ability to provide customized products according to your process requirements.

The rubber sheets and rubber sheets produced by Strudex have the following advantages

1. Lightweight and energy-efficient.

2. Strong impact resistance and low noise.

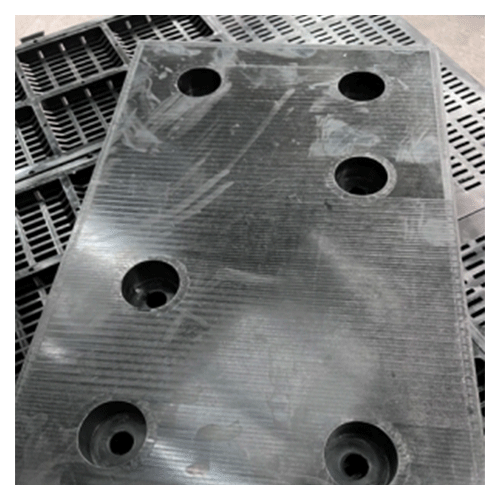

3. Novel structure, easy disassembly and assembly; Suitable for the vast majority of mainstream screening machines.

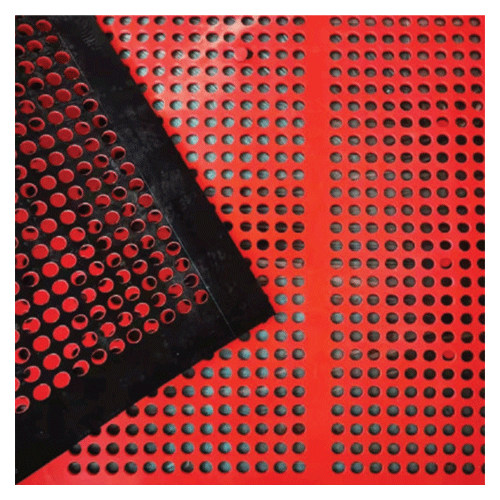

4. Good rebound, high material bounce frequency, and high screening efficiency.

5. The sieve aperture can deform within a certain limit, reducing the probability of the aperture being blocked by the material.

6. The sieve plate can use different material skeletons during the molding process to extend its service life.

7. Products with a lifespan of 6-24 months can be designed according to user requirements and usage conditions.

8. Different aperture screens and installation methods can be designed according to user requirements.