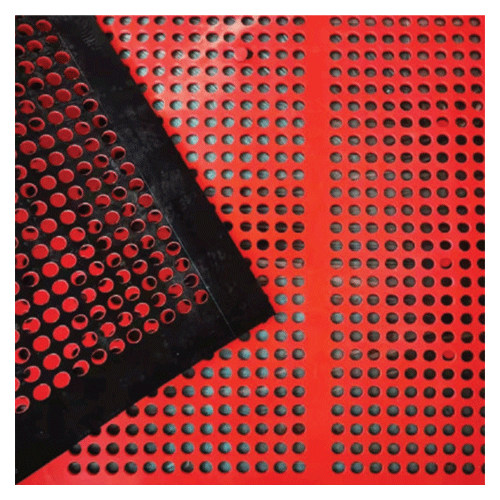

Wear resistant rubber sieve plate, a type of rubber plate. The metal skeleton is embedded in the rubber plate, with evenly distributed holes of the same specifications on top, which has good wear resistance and low noise. It is the main component of the vibrating screen, mainly used for coal classification, ore sorting, and other aspects, widely used in the coal selection and beneficiation industry.

Development mechanism, structural design

- Core technology

Compared with metal welded parts, the wear rate of wear-resistant rubber sieve plate is very low. In addition to the wear resistance of general wear-resistant materials, it also has certain oxidation and corrosion resistance. Its service life in self centering vibrating screen is more than 10 times longer than that of ordinary metal sieve plate, and the effect is significant. In addition, Binzhou Hengtai Network Industry Co., Ltd. adopts a unique wet nano rubber process, which has superior wear resistance index, tear strength and resilience. Its technical level is at the international leading level and is widely used.

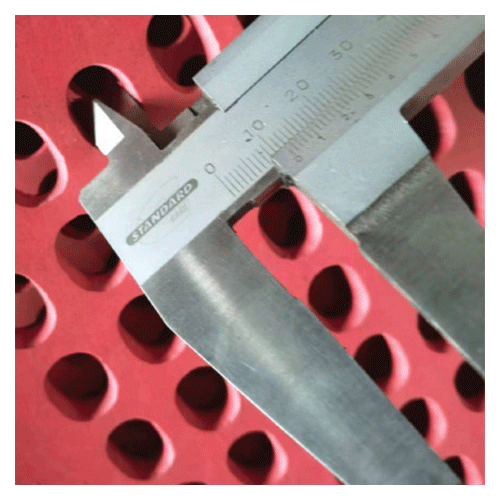

The sieve plate design has three layers of adhesive: a bottom strong layer, a middle buffer layer, and an upper cover layer. The main rubber material has high elasticity, wear resistance, corrosion resistance, and sufficient strength. The sieve holes are conical in shape, and the sieve surface has strong self-cleaning ability.

- Formula design

The adhesive used for wear-resistant rubber screen plates includes covering adhesive and wiping adhesive. Due to the fact that the skeleton material is polyester curtain fabric, its adhesive performance is similar to polyester canvas. Therefore, traditional polyester canvas adhesive is chosen as the adhesive for the sieve plate, and the effect is good. The usage conditions of rubber screen plate require it to have good wear resistance, high strength, good elasticity, impact resistance, and tear resistance. Therefore, the principle for determining the formula of the covering adhesive is: high wear resistance, high strength, moderate elasticity, and good processing performance.

- Process Research

In order to meet the special usage environment and complex load conditions requirements of rubber sieve plates, the following are summarized: plasticizing, mixing, rolling, pre forming, and vulcanization.

Product advantages

01/ Performance advantages

The anti blocking and anti sticking flexible screen produced by Hengtai maintains high elasticity during vibration screening. Under the action of a certain vibration frequency and amplitude of the screening machine, multiple vibrations, deformations, and responses continuously bounce, shake, and screen wet and sticky materials from the screen surface, improving the self-cleaning function of the screen and meeting the requirements for screening wet and sticky materials in dry screening, avoiding the phenomenon of clogging and sticking holes. It is especially suitable for screening medium and fine-grained materials in wet and sticky states. The service life is 6-10 times longer than that of ordinary woven screens.

The anti blocking and anti sticking flexible screen produced by Hengtai maintains high elasticity during vibration screening. Under the action of a certain vibration frequency and amplitude of the screening machine, multiple vibrations, deformations, and responses continuously bounce, shake, and screen wet and sticky materials from the screen surface, improving the self-cleaning function of the screen and meeting the requirements for screening wet and sticky materials in dry screening, avoiding the phenomenon of clogging and sticking holes. It is especially suitable for screening medium and fine-grained materials in wet and sticky states. The service life is 6-10 times longer than that of ordinary woven screens.

02/ Use case

When screening materials, there are often working conditions with high humidity, where semi dry and semi wet fine materials enter the screen surface and immediately adhere to the screen, resulting in a lack of self-cleaning performance of the screen mesh, which cannot effectively separate wet and sticky materials from the screen mesh, causing large-scale blockage of the material and affecting screening efficiency. If all the screens are made of low hardness, the strength of the screen mesh will be reduced, and it will be limited when subjected to heavy load impact. This product scientifically utilizes the vibration of flexible working surfaces, greatly improving the self-cleaning performance of the screen mesh, enhancing the efficiency of dry screening, and reducing maintenance costs and labor intensity for employees.

03/ Product Features

1. It can highly absorb impact force, so it has excellent wear resistance. Under normal circumstances, wear-resistant rubber screen plates have a working life 4-8 times longer than metal screen plates.

2. Low noise and minimal dust. According to field measurements, using wear-resistant rubber screen plates for the same screening machine can reduce noise by 5-20 decibels compared to using metal screen plates, and significantly reduce dust flying, creating a peaceful and clean working environment in the workshop.

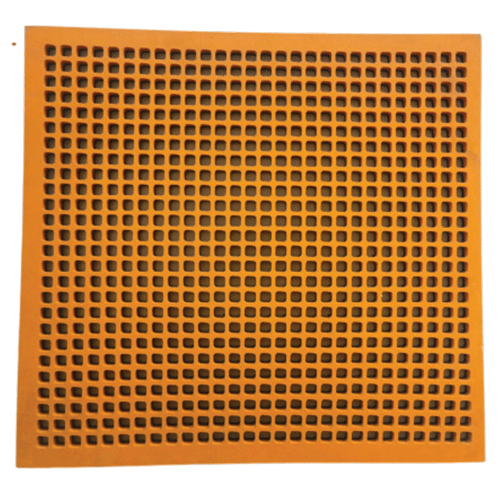

3. Due to the structure of the wear-resistant rubber sieve plate itself, its sieve holes have relaxation properties (i.e. small periodic changes in aperture under external force), and the sieve holes are inverted conical, making them less prone to clogging and having good self-cleaning ability.

4. High screening accuracy. Due to the fact that the sieve holes are punched with specialized forming tools in one go, the size is accurate and has a screening accuracy that is impossible for woven sieve surfaces.