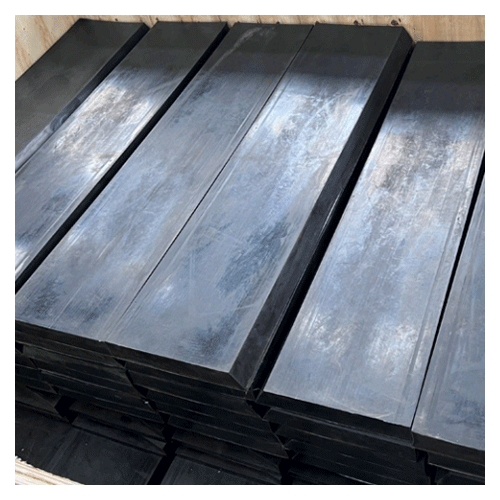

Anti-blocking rubber screen panel

Made of natural rubber with a hardness of 40 Shore A, due to its excellent resilience, it can avoid hole plugging and also has excellent wear resistance.

The rubber screen panel can ensure that the entire screen surface is free from blockage and material accumulation, reduce noise, and provide excellent wear resistance, thereby maintaining efficient screening, saving costs and improving benefits.

Strudex's rubber screen panel sieve hole shape, size, sieve thickness and fixing method are constantly improving. We have the ability to provide you with customized products according to your process requirements.

Product application case

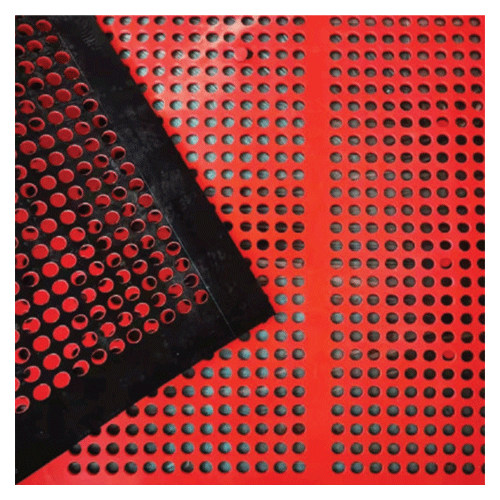

Solve the plugging problem of aggregate screening

The first case comes from Jiangxi Province in the south of China. The customer's area has a lot of precipitation in summer, which makes the materials they screen wet. These materials will block the holes and stick to the surface of the panel, requiring manual cleaning of the machine every two hours. The customer tried the steel screen panel and the polyurethane screen panel respectively, but none of them solved the problem of hole blocking.

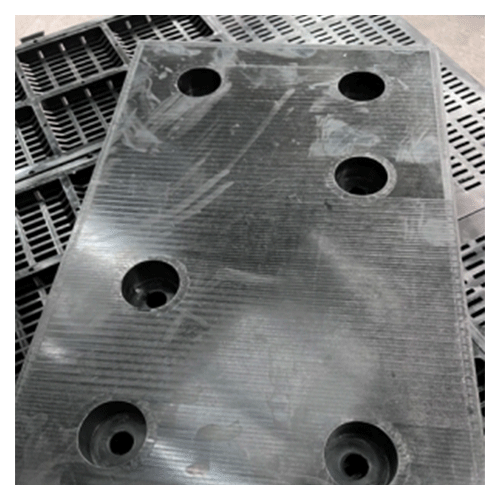

On April 8* , we provided the customer with 4 rows of rubber screen panels for experiment, and tried to solve the problem of hole plugging with high elasticity and wear-resistant rubber with a hardness of 40ShoreA.

Due to the high elasticity of rubber, wet materials will hardly stay on the surface of the screen panels. The customer checked after the machine stopped and found that the plugging rate of our rubber screen panel is extremely low, almostzer0.

Three months later, we visited the customer again and entered the machine to check the wear of the rubber screen panel. The following are the pictures we took on site. It can be seen that there is no obvious wear and tear on the screening area of the rubber screen panel. The customer told us that there have been no more plugged holes in these three months, which has reduced machine downtime.