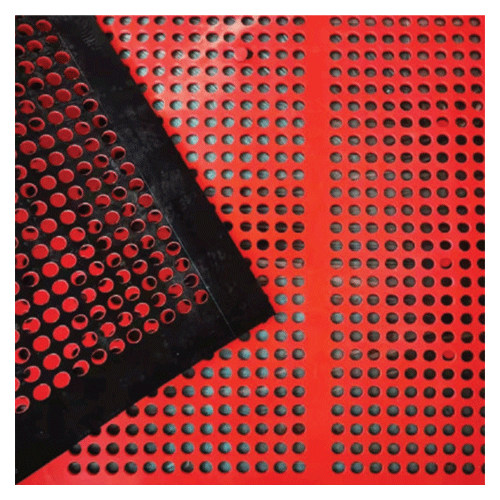

The wear-resistant rubber sieve meshes are available in thicknesses of 20mm, 25mm, and 30mm, with commonly used hole shapes including square, circular, and rectangular.

Users can select the sieve mesh according to their needs, and customized sieve meshes of special specifications and performance can be ordered individually.

The wear-resistant rubber sieve mesh is made by firmly bonding special rubber to a skeleton consisting of steel wire ropes and tension hooks. It exhibits excellent properties such as high elasticity, high wear resistance, impact resistance, tear resistance, and a long service life. It is compatible with heavy-duty screening equipment in industries such as mining and mineral processing, metallurgy, coking, building materials, and coal preparation.

Product Features:

- High Impact Absorption: The wear-resistant rubber sieve mesh demonstrates exceptional wear resistance. Under normal conditions, its service life is more than 2-3 times that of domestically produced polyurethane sieve meshes and 4-8 times that of metal sieve meshes.

- Low Noise and Dust Reduction: Field measurements show that using wear-resistant rubber sieve meshes in the same screening machine can reduce noise by 5-20 decibels compared to metal sieve meshes. Additionally, it significantly minimizes dust dispersal, creating a quieter and cleaner work environment in the workshop.

- Lightweight and Easy to Install, Load, and Transport: A 1-square-meter sieve mesh with a thickness of 15mm weighs less than 15Kg. This not only reduces the weight of the equipment but also correspondingly decreases the power consumption of the screening machine.

- Elastic Sieve Holes: The sieve holes of the wear-resistant rubber sieve mesh possess relaxation and tension properties. Under external force, the aperture undergoes small periodic changes, and the inverted conical shape of the sieve holes makes it difficult for them to become clogged, providing good self-cleaning ability.

- High Screening Accuracy: The sieve holes are made using specialized molds, ensuring precise dimensions and achieving a screening accuracy that woven sieve surfaces cannot match.

Comparative Data

| Ordinary | Huanai | |

| Polyurethane Sieve Mesh | Tension-Type Rubber Sieve Mesh | |

| Sieve Mesh Material | Polyurethane | Natural Rubber(imported) |

| Sieve Mesh Elasticity | Non-elastic | High Elasticity |

| Fixation Method | Tension-type | Tension-type |

| Ore Blocking Rate | 40%50% | ~0% |

| Material Adhesion Rate | >20% | ~0% |

| Effective Opening Rate | 18.88% | 31% |

| Service Life | 2-3 months | Over 6 months |

| Screening Efficiency | 60-70% | 95% |