Users can select sieve meshes of special specifications and performance according to their needs, and customized orders are available for individual requirements.

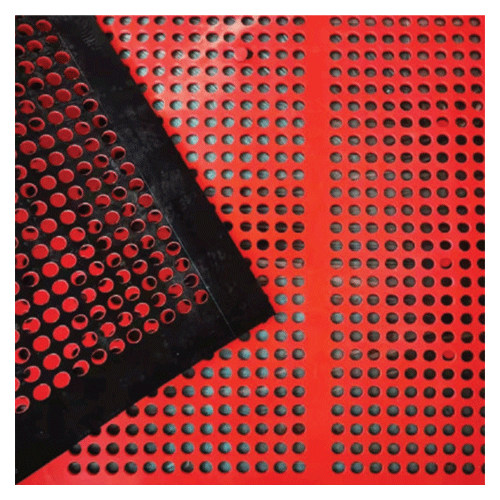

A flame-retardant, antistatic, and wear-resistant rubber sieve mesh for underground coal mines has been developed to overcome the shortcomings of existing technologies, meeting both the screening requirements of screening machines and the safety performance standards for coal mines. It is composed of several sieve mesh pieces, each of which includes tension hooks and a sieve plate section. The sieve plate section is divided into an open-hole area and a reinforced blind area. The distinguishing feature is that the sieve plate is made of a proprietary high-performance rubber compound and a reinforcing layer through vulcanization. The high-performance rubber exhibits properties such as flame retardancy, antistatic properties, wear resistance, and tear resistance. The reinforcing skeleton is made of multi-layer dipped aramid cord fabric. The sieve plate is divided into an open-hole area and a reinforced rib area. The tension hooks are installed on the edges of the sieve mesh using bolts. This product is suitable for screening operations in underground coal mines, featuring light weight, easy installation and maintenance, high wear resistance, strong self-cleaning ability, low energy consumption, long service life, as well as flame-retardant and antistatic properties that meet the safety performance requirements for use in coal mines.