Product Features:

Long service life and high durability

The service life of injection-molded wear-resistant rubber screen plates is increased by at least 30%.

The retaining bars contribute to higher productivity and longer lifespan.

Molded screening holes reduce the risk of material blockage.

Higher heat resistance.

No material blockage or adhesion, ensuring precise screening

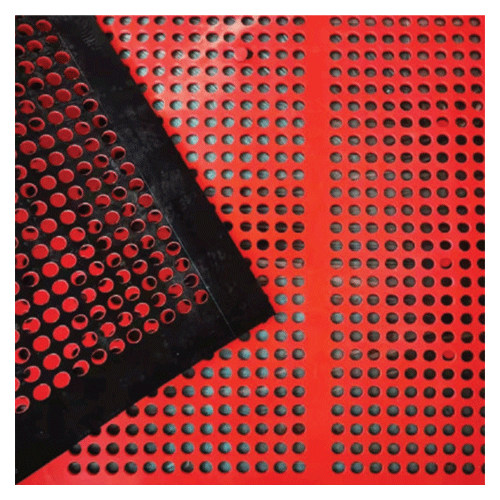

The super-elastic membrane material and molded screening holes prevent material blockage and adhesion.

The screening surface remains clean at all times, even when screening materials with high moisture content through injection molding.

Rubber manufacturing technology ensures consistent material performance across the entire screening surface.

High screening accuracy, making it an ideal choice for fine material screening.

Reduced labor intensity

Rubber screen plates can be partially replaced, with simple installation that requires only one person for 3-5 minutes to replace a single plate.

Lower screen mesh costs

The average lifespan of a set of screen plates is approximately two years (with partial replacement of approximately 60% of the screen plates each year).

Common Specifications of the Product

Screen Plate Dimensions (mm): 305305, 305610, 610*610, and other sizes are customizable

Screen Hole Size (mm): Customizable according to customer requirements

Installation Methods: Bolts, expansion nails (plugs), rail seats (clips), sliding grooves, etc.

Comparative Data

| Ordinary | Huanai | |

| Polyurethane Sieve Mesh | Tension-Type Rubber Sieve Mesh | |

| Sieve Mesh Material | Polyurethane | Natural Rubber(imported) |

| Sieve Mesh Elasticity | Non-elastic | High Elasticity |

| Fixation Method | Snap-fit | Snap-fit |

| Ore Blocking Rate | 40%50% | ~0% |

| Material Adhesion Rate | >20% | ~0% |

| Effective Opening Rate | 18.88% | 31% |

| Service Life | 2-3 months | Over 6 months |

| Screening Efficiency | 60-70% | 95% |