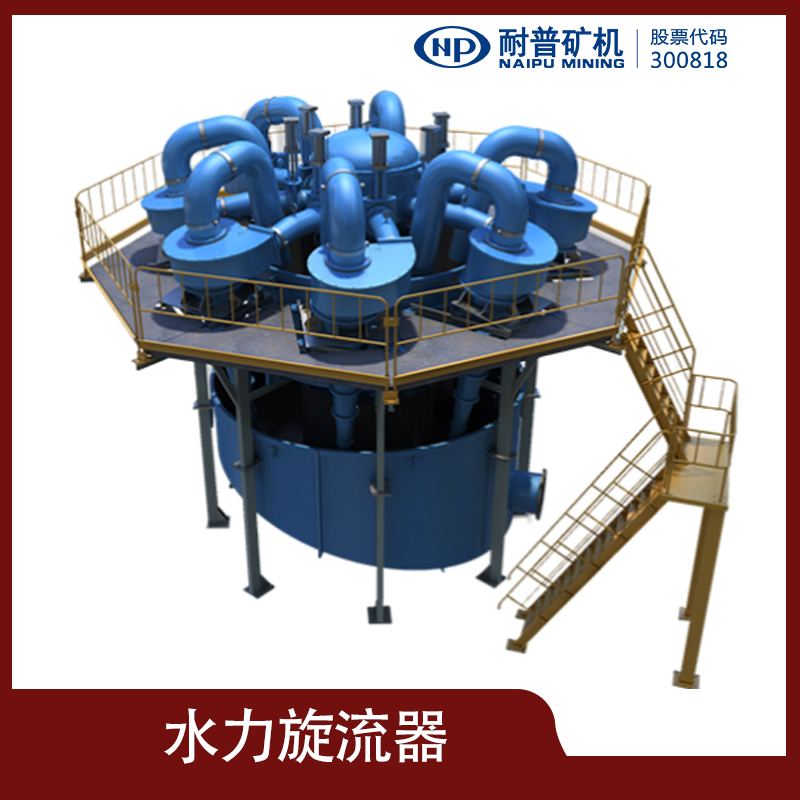

Cyclone selection determines classification efficiency and service life.

Cyclone series selection: Standard type, variable cone type, long cone type.

Cyclone material selection: Wear-resistant rubber, polyurethane, composite materials.

Cyclone structural dimensions: Individual specifications, sand nozzle diameter, overflow pipe diameter.

Recommended operating parameters: Ore feed pressure, feed concentration.

|

Model |

Diameter of feeding port(mm) |

Maximum feeding grain size(mm) |

Ore pressure(Mpa)

|

Grading granularity(μm) |

Processing capacity(m²/h) |

Length(mm) |

Width(mm) |

Height(mm) |

Weight(kg) |

|

NP-X838 |

320 |

22 |

0.03-0.15 |

100-350 |

580-800 |

1600 |

1300 |

3300 |

1840 |

|

NP-X660 |

187 |

16 |

0.03-0.2 |

74-220 |

260-500 |

1250 |

880 |

3100 |

1010 |

|

NP-X500 |

130 |

10 |

0.03-0.3 |

74-220 |

260-400 |

1100 |

820 |

2780 |

700 |

|

NP-X350 |

81 |

7 |

0.03-0.3 |

50-200 |

105-160 |

825 |

290 |

2000 |

590 |

|

NP-X250 |

74 |

3 |

0.03-0.3 |

30-100 |

55-100 |

570 |

415 |

1172 |

92 |

|

NP-X150 |

39 |

1.5 |

0.05-0.4 |

20-100 |

15-30 |

380 |

345 |

953 |

30 |

Professional installation and debugging guidance ensures that the on-site operation of the cyclone achieves the desired classification effect.

|

|

Structural rate |

Processing Capacity |

Overflow Width |

Separation Efficiency |

|

Column diameter(D) |

↑ |

↑ |

↑ |

↓ |

|

Feeding port diameter(d) |

↑ |

↑ |

↑ |

↓ |

|

Overflow pipe diameter(do) |

↑ |

↑ |

↑ |

↓ |

|

Sedimentation port diameter(du) |

↑ |

No effect |

↓ |

↑ |

|

Insertion depth of overflow pipe(h) |

Too large or too small |

No effect |

↑ |

↓ |

|

Height of cylindrical section(H) |

Too high or too low |

↑ |

↑ |

↓ |

|

Cone angle(a) |

↑ |

↑ |

↑ |

↓ |

By adjusting the length of the cyclone cylinder, optimizing the cone angle, and improving the geometric parameters of the sand discharge port, the cyclone can achieve the best state under various operating conditions.

Advanced structural design:

- Cyclone chamber inlet:

1.Adopts a involute inlet with spiral entry.

2.Extends the inflow channel, providing pre-classification for coarse particles.

3.Smooth transition of inlet flow velocity reduces turbulence.

- Cone:

1.Utilizes a variable cone structure.

2.The large cone angle at the upper part increases the tangential velocity of the slurry.

3.The small cone angle at the lower part prolongs the retention and classification time of the materials, improving classification accuracy.

Application of Wear-Resistant Material

Wear-resistant Rubber

|

Hardness (Shaw A) |

Tensile strength (MPa) ≥ |

Elongation (%) ≥ |

Tear strength (N/mm) ≥ |

Springback (%) ≥ |

Proportion (g/cm3) |

Temperature range(℃) |

|

36±5 |

22 |

700 |

40 |

70 |

0.96±0.01 |

-20~+75 |

Polyurethane

|

Hardness (Shaw A) |

Tensile strength (MPa) ≥ |

Elongation (%) ≥ |

Tear strength (N/mm) ≥ |

Springback (%) ≥ |

Proportion (g/cm3) |

Temperature range(℃) |

|

75±5 |

23 |

430 |

60 |

55 |

1.08 |

-20~+75 |

The service life of the inner lining of the main components of the cyclone

|

No. |

Name |

Replacement cycle (months) |

|

1 |

Sand discharge nozzle lining |

6-12 |

|

2 |

Lower cone lining |

10-12 |

|

3 |

Middle cone lining |

10-12 |

|

4 |

Upper cone lining |

15-18 |

|

5 |

Cylindrical section lining |

24-36 |

|

6 |

Cyclone chamber lining |

24-36 |

|

7 |

Upper cover lining |

24-30 |

|

8 |

Overflow pipe |

12-15 |

Application conditions

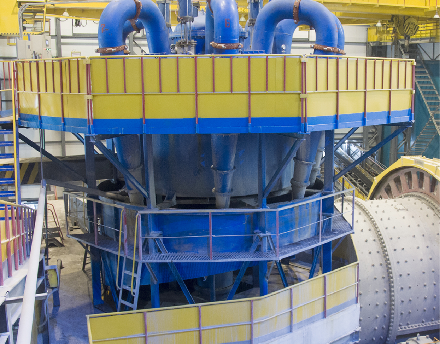

- Closed-circuit grinding in the first stage

The cyclone classifier forms a closed-circuit grinding and classification system with a first-stage grinding ball mill, which has the advantages of small footprint, high classification efficiency, easy adjustment of sand return load, and more reasonable overflow particle composition.

- Closed-circuit grinding or regrinding and classification of fines or middlings

Reasonable structural design and measures such as higher inner surface finish reduce the disturbance of the internal flow field of the cyclone, effectively improving classification efficiency and accuracy.

- Concentration and dewatering of fines (or tailings)

Generally, cyclones with small cone angles or multi-cone structures are selected to obtain higher underflow concentration and underflow yield.

Cyclone characteristics

1. Higher processing capacity.

2. Longer service life of vulnerable parts.

3. Wider application range.

4. Finer classification granularity.

5. Higher efficiency.

6. Providing design and selection services.

.jpg)