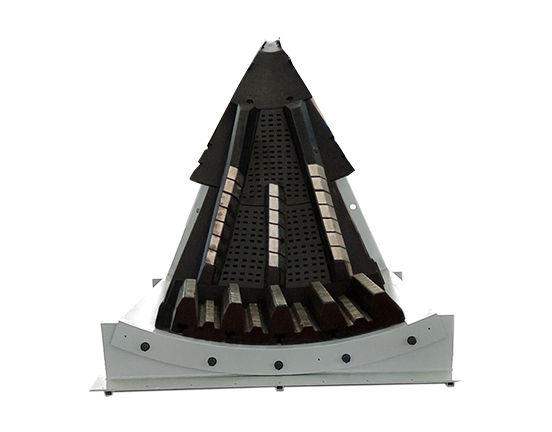

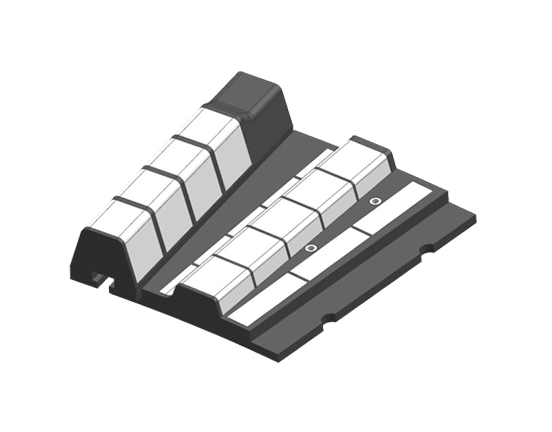

Composite Liner Plate (Rubber + Wear-resistant Alloy)

The composite liner plate is a new type of liner plate developed by Naipu to address the issues of intermittent cracking and insufficient pre-tightening force of large semi-autogenous mill liner plates, which result in slurry leakage, mill stoppages, and excessive grinding. It significantly improves the service life of the liner plate and the efficiency of the mill operation, receiving positive feedback from users. Structural forms include metal lifting strips + rubber liner plates, metal lifting strips + rubber composite liner plates, and composite lifting strips + rubber composite liner plates, which can be combined and designed according to different working conditions.

Performance Features of Composite Liner Plate:

1. mpact resistance and wear resistance.

2. Long service life and high cost-effectiveness.

3. Lower noise compared to metal liner plates.

4. Lightweight and easy to assemble and disassemble.

Applications:

1. Discharge end lifters, grates, and cylinder liner plates of semi-autogenous mills and autogenous mills.

2. Complete sets of liner plates for first and second stage ball mills.

.jpg)