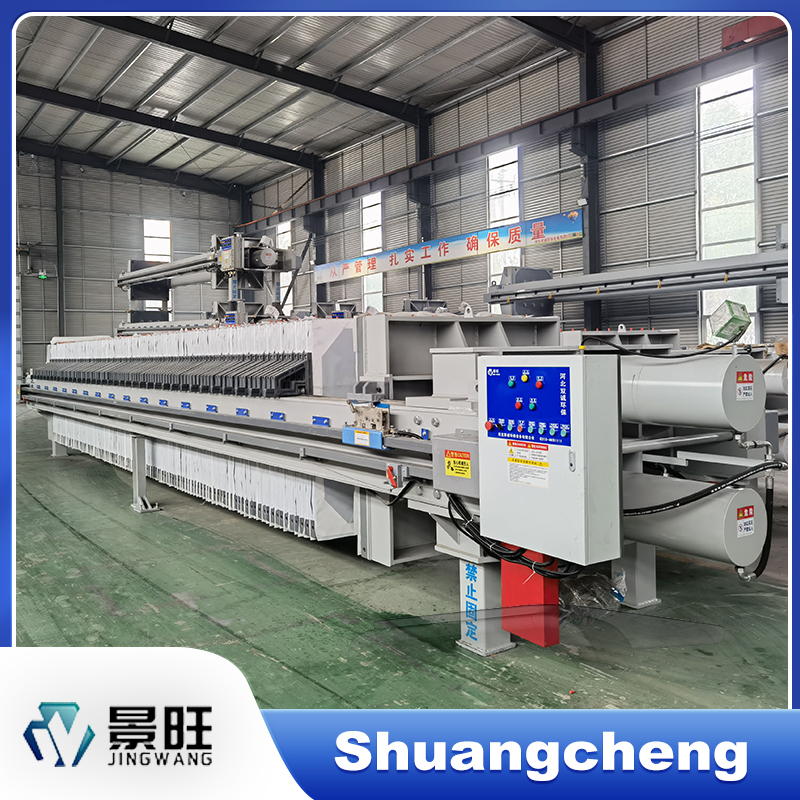

500㎡ Chamber-type Open-Discharge Program-controlled Automatic Plate-Shifting Filter Press

In the field of industrial solid-liquid separation, this 500-square-meter filter press is a powerful and highly efficient equipment. Its remote control operation capability brings significant convenience to modern industrial production.

This filter press features a chamber-type structure composed of multiple filter plates, forming filtration chambers with a total area of 500 square meters - providing ample space for large-scale solid-liquid separation. The open-discharge design offers clear visibility of the filtrate discharge path, allowing operators to directly observe filtrate conditions (flow rate, clarity, etc.) to monitor filtration progress and effectiveness.

The automatic plate-shifting mechanism is key to enhancing work efficiency. Upon completion of a filtration cycle, this device automatically opens the filter plates in sequence, efficiently discharging the filter cakes formed in the chambers. This significantly reduces labor requirements and time costs, enabling rapid transition to the next operational cycle.

Applications:

Widely used in industries such as chemical, light industry, petroleum, pharmaceuticals, food, resource development, metallurgy, coal mining, environmental protection, and wastewater treatment (e.g., chemical wastewater, smelting wastewater, electroplating wastewater, tannery wastewater, dyeing wastewater, pharmaceutical wastewater, aquaculture wastewater, slaughterhouse wastewater, sand washing wastewater, construction pile wastewater, stone cutting and polishing wastewater, etc.), earning widespread user acclaim.

Our company produces various models of chamber filter presses, hydraulic filter presses, membrane filter presses, fully automatic filter presses, and related accessories, all of high quality and comprehensive specifications.

(1) Sizes: 630, 800, 1000, 1250, 1500, 1600, and 2000 models.

(2) Maximum filtration area: up to 1000 m².

(3) Filter plate materials: cast iron, reinforced polypropylene, fiberglass polypropylene, etc.

(4) Flow types: bright flow, dark flow, washable, non-washable, center feed, corner feed, and more.

(5) Compression methods: mechanical and hydraulic cylinder compression. Custom solutions are available for special requirements.