High pressure diaphragm filter press: Firstly, in terms of working principle, an ordinary filter press mainly compacts solid particles in the suspension onto the filter cloth through pressure to form a filter cake, thereby achieving solid-liquid separation. In contrast, the high-pressure diaphragm filter press adds a diaphragm squeezing function on this basis. Under the high pressure of the squeezing pump, the diaphragm compresses further into the filter chamber, squeezing the filter cake to fully remove moisture from it, thus improving the solid-liquid separation effect.

The main difference between the diaphragm filter press and the ordinary chamber filter press is the addition of an elastic membrane diaphragm plate between the filter plate and the filter cloth. During operation, after the feeding is completed, high-pressure fluid medium can be injected between the filter plate and the diaphragm, causing the entire diaphragm to bulge and compress the filter cake, thereby achieving further dewatering of the filter cake—this is called squeeze filtration. The first step is positive-pressure dewatering, also known as slurry feeding dewatering. A certain number of filter plates are tightly arranged in a row under strong mechanical force, forming filter chambers between the surfaces of the filter plates. The filtering material is fed into the filter chambers under high positive pressure. The solid part of the filtering material is intercepted by the filtering medium (such as the filter cloth) to form a filter cake, while the liquid part passes through the filtering medium and is discharged from the filter chamber, achieving solid-liquid separation.

Advantages:

Additionally, the high-pressure diaphragm filter press offers advantages such as high automation, simple operation, and easy maintenance. Its advanced control system enables remote monitoring and operation, significantly improving production efficiency and convenience. At the same time, the reasonable structural design of the high-pressure diaphragm filter press ensures more stable and reliable performance during long-term operation, reducing failure rates and maintenance costs.

Applications:

It is widely used in industries such as chemical, light industry, petroleum, pharmaceuticals, food, resource development, metallurgy and coal, environmental protection, and wastewater treatment (including chemical wastewater, smelting wastewater, electroplating wastewater, tannery wastewater, printing and dyeing wastewater, pharmaceutical wastewater, aquaculture wastewater, slaughterhouse wastewater, sand washing wastewater, construction pile wastewater, stone cutting and polishing wastewater, etc.), and is highly welcomed by users.

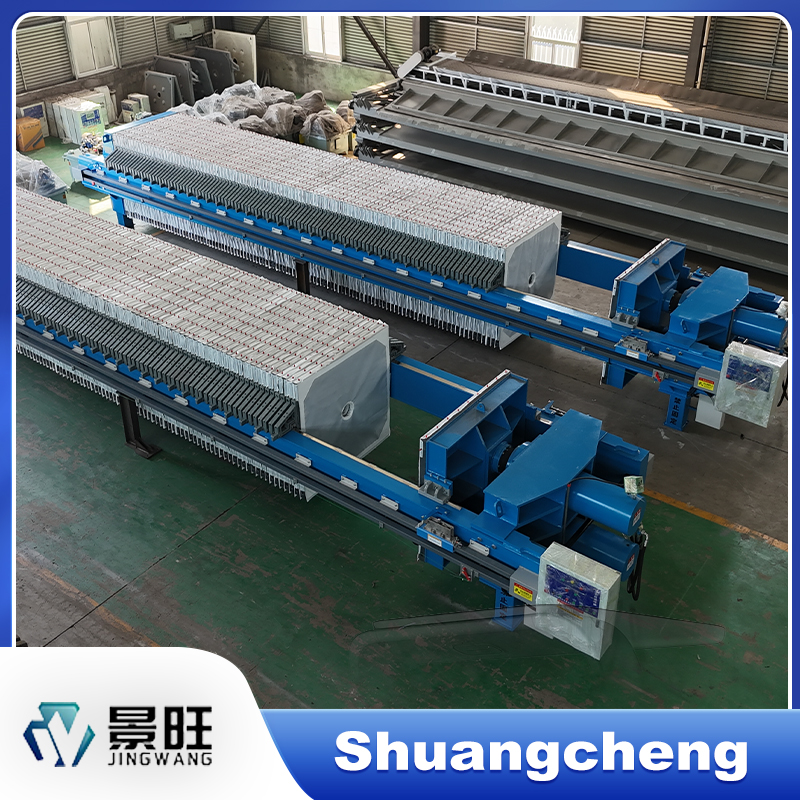

Our company produces various models of chamber filter presses, hydraulic filter presses, diaphragm filter presses, fully automatic filter presses, and filter press accessories, all of reliable quality and complete specifications.

(1) Specifications include: 630 type, 800 type, 1000 type, 1250 type, 1500 type, 1600 type, and 2000 type.

(2) The maximum filtration area reaches 1000m².

(3) Filter plate materials include cast iron, reinforced polypropylene, glass fiber polypropylene, etc.

(4) Liquid flow forms include open flow, hidden flow, washable, non-washable, center feeding, corner feeding, and more.

(5) Filter plate pressing methods include mechanical pressing and hydraulic cylinder pressing. For special requirements of filter presses, customized solutions can be discussed separately.

Technical Specifications:

XMAZG/2000-U Program Controlled Automatic High Pressure Diaphragm Filter Press

| Technical Data: Work journey 700. Maximum journey 1000. | ||||||||

| U-Plastic plate & frame(Thickness 98/85, Filter Cloth Thickness 1mm/plate) | ||||||||

| Filtration area(m²) | Number of Plate |

Cake thickness (mm) |

Chamber volume(m³) |

Unit weight (kg) |

Anchor center (mm) |

Overall dimensions(mm) | ||

| Length | Width | Height | ||||||

| *500 | 35/34 | 40 | 10.00 | 46994 | 8585 | 10310 | 3100 | 2450 |

| *600 | 42/41 | 12.00 | 48956 | 9873 | 11598 | |||

| *700 | 49/48 | 14.00 | 51350 | 11161 | 12886 | |||

| *750 | 53/52 | 15.15 | 53850 | 11897 | 13622 | |||

| *800 | 56/55 | 16.00 | 55240 | 12449 | 14174 | |||

| *900 | 63/62 | 18.00 | 64214 | 13737 | 15462 | |||

| *1000 | 70/69 | 20.00 | 68511 | 15025 | 16750 | |||

14.png)