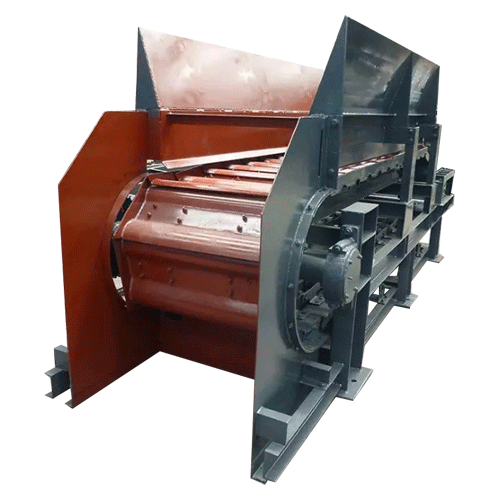

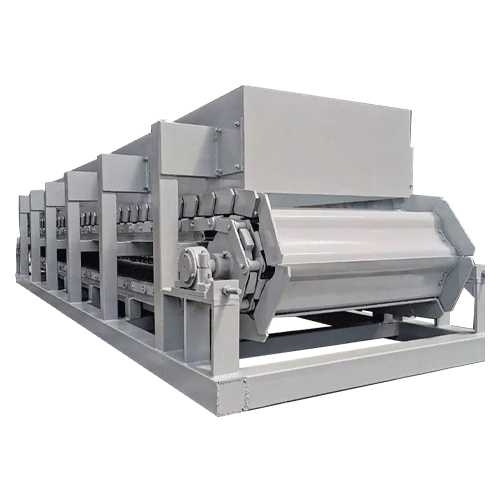

轻型、中型、重型板式喂料机

LIGHT,MEDIUM,HEAVY DUTY APRON FEEDER

一、概述Summary

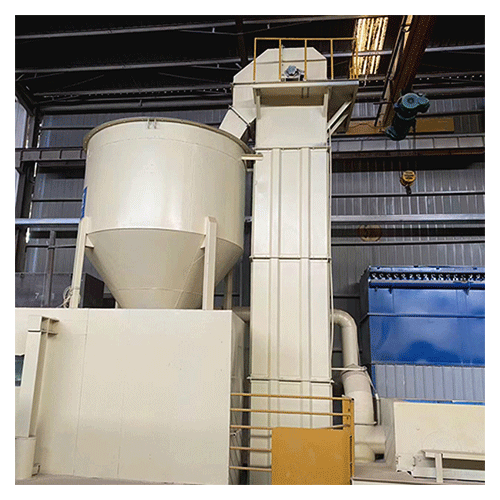

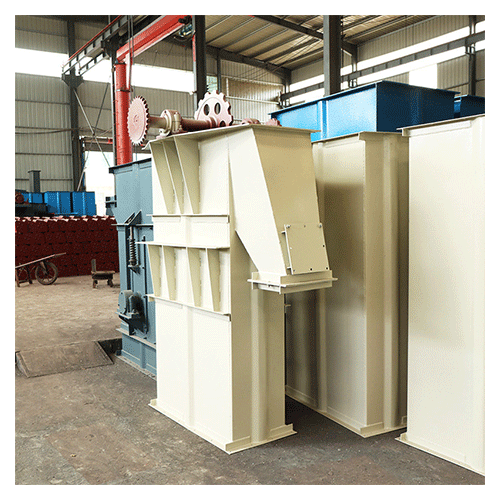

板式喂料机被广泛用于建材、冶金、电力、煤炭、化工、铸造等行业中,特别适宜于输送一些温度高、块度大、具有锋利棱角和磨琢性强的固体物料。在水泥行业中,是立窑窑尾熟料输送的最佳选择。

板式喂料机的性能特点:

牵弓引链采用长节距板式销轴滚子链,链条个零件均采用合金钢材料,并经过科学的热处理,耐磨性能好、拉伸强度高、使用寿命长,采用冲压槽体,中间用横筋加强,槽体性能好,承载能力大。槽体底板圆弧搭接,防止物料泄漏。驱动电机采用调速电机,运行速度可调,以便更合理地选择输送量。布置形式多样、可水平、倾斜布置,还有多种水平、倾斜组合布置。单机输送长度小于等于60m,提升高度小于等于30m。最大输送倾角0~75°。物料温度小于等于600℃。型号可分为轻型板式喂料机、中型板式喂料机、重型板式喂料机

The Apron Feeder is specially applicable to conveysolid materials which are hot. big block, sharp andfrictional. Thesemachines usually are used inbuilding. metallurgy. electric power, coal. chemicaland foundry industry, etc. These scraper feeding machines are .the bestchoice for tr anspor ting clinker discharging fromshaft kiln.

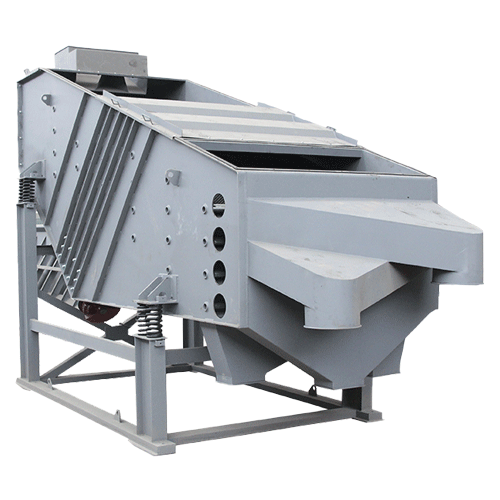

二、外形结构图及主要技术参数TechnicalParameters And Outside View

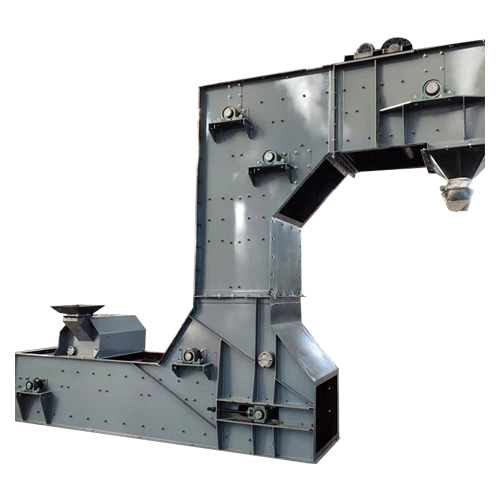

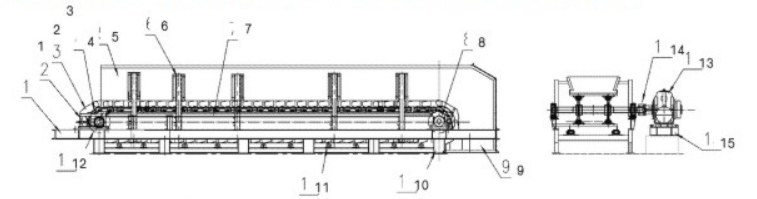

1、中部支架 2、拉紧装置 3、链板 4、链条 5、密封罩 6、密封罩支腿 7、导轨 8、头部链轮及轴承座

9、头部出料口 10、支腿 11、托轮 12、尾部链轮 13、驱动装置 14、联轴器 15、驱动架

1. Mid Support 2. Tensioner 3.Link Plate 4. Chain 5. Enclosed Fitting 6. Enclosed Fitting Su-

pport 7. Guide Rail 8. Head Wheel and Bearing 9. Outlet 10. Support 11. Under Roller 12. Tail

Wheel 13. Drive Unit 14. Coupling 15. Support of Drive Unit

图23-1重型板式喂料机的外形结构图

Figure 23-1 Heavy Duty Apron Feeder Outside Vie w

表23-1重型板式喂料机的技术参数

Table 23-1 Heavy Duty Apron Feeder Technical Parameters

| 型号 Spec. |

槽板宽度(mm) Plate Width |

头尾轮轴中心距 (mm)C-C Length |

速度(m/s) Speed |

给料粒度(mm) Granule Size |

处理能力(t/h) Capacity |

电动机功率(kw) Power |

参考重量(kg) Ref.Weight |

| WBZ160-9 | 1600 | 9000 | 0.01-0.07 | 27-270 | 30 | 50000 | |

| WBZ180-8 | 1800 | 8000 | 0.01-0.07 | ≤1000 | ≤500 | 37 | 59000 |

| WBZ180-8.75 | 1800 | 8750 | 0.01-0.07 | ≤1000 | ≤500 | 37 | 61000 |

| WBZ180-9 | 1800 | 9000 | 0.01-0.07 | ≤1000 | ≤500 | 37 | 63000 |

| WBZ180-9.8 | 1800 | 9800 | 0.01-0.07 | ≤1000 | ≤500 | 37 | 63000 |

| WBZ180-10 | 1800 | 10000 | 0.01-0.07 | ≤1000 | s500 | 37 | 66000 |

| WBZ200-9.8 | 2000 | 9800 | 0.01-0.07 | ≤1000 | ≤500 | 37 | 82000 |

| WBZ220-10 | 1800 | 10000 | 0.01-0.07 | ≤1200 | ≤700 | 45 | 85000 |

| WBZ230-10 | 2300 | 10000 | 0.01-0.07 | ≤1500 | ≤800 | 45 | 86000 |

| WBZ240-10 | 2400 | 10000 | 0.02-0.06 | ≤1600 | ≤850 | 2×37 | 95000 |

| WBZ250-11.5 | 2500 | 11500 | 0.01-0.07 | ≤1800 | 550-900 | 2×45 | 105000 |

表23-2轻型板式喂料机的技术参数

Table 23-2 Light Duty Apron Feeder Technical Parameters

| 型号 Spec. |

槽板宽度(mm) Plate Width |

头尾轮轴中心距 (mm)C-C Length | 速度(m/s) Speed | 给料粒度(mm) Granule Size | 处理能力(t/h) Capacity | 电动机功率(kw) Power | 参考重量(kg) Ref.Weight |

| WBQ500-2 | 500 | 2000 | 7-88 | 0.05-0.4 | 180 | 1.1-3 | 2500 |

| WBQ500-3 | 3000 | 3000 | |||||

| WBQ500-4.5 | 4500 | 3500 | |||||

| WBQ500-6 | 6000 | 4000 | |||||

| WBQ500-9 | 9000 | 1.5-4 | 4800 | ||||

| WBQ500-12 | 12000 | 5600 | |||||

| WBQ630-3 | 630 | 3000 | 11-175 | 0.04-0.4 | 200 | 1.5-4 | 3200 |

| WBQ630-4.5 | 4500 | 4000 | |||||

| WBQ630-6 | 6000 | 4700 | |||||

| WBQ630-9 | 9000 | 6000 | |||||

| WBQ630-12 | 12000 | 2.2-5.5 | 7500 | ||||

| WBQ630-15 | 15000 | 9000 | |||||

| WBQ800-3 | 800 | 3000 | 19-38 | 0.04-0.4 | 350 | 2.2-5.5 | 3600 |

| WBQ800-4.5 | 4500 | 4400 | |||||

| WBQ800-6 | 6000 | 2.2-5.5 | 5200 | ||||

| WBQ800-9 | 9000 | 6800 | |||||

| WBQ800-12 | 12000 | 8200 | |||||

| WBQ80-15 | 15000 | 9600 | |||||

| WBQ800-18 | 18000 | 11000 |

表23-3中型板式喂料机的技术参数

Table 23-3 Medium Duty Apron Feeder Technical Parameters

| 型号 Spec. |

槽板宽度(mm) Plate Width |

头尾轮轴中心距 mm)C-C Length | 速度(m/s) Speed | 给料粒度(mm) Granule Size | 处理能力(t/h) Capacity | 电动机功率(kw) Power | 参考重量(kg) Ref.Weight |

| WBL100-6 | 1000 | 6000 | 0.01-0.1 | ≤500 | 80-160 | 11 | 15560 |

| WBL100-12 | 1000 | 12000 | 0.05-0.1 | ≤500 | 60-130 | 15 | 23525 |

| WBL120-4 | 1200 | 4000 | 0.014-0.08 | ≤600 | 45-150 | 111 | 12660 |

| WBL120-6 | 1200 | 6000 | 0.01-0.1 | ≤600 | 80-160 | 11 | 15660 |

| WBL120-11 | 1200 | 11000 | 0.01-0.1 | ≤600 | 50-100 | 15 | 23535 |

| WBL120-19 | 1200 | 19000 | 0.014-0.09 | ≤600 | 45-150 | 22 | 41058 |

| WBL125-6 | 1250 | 6000 | 0.014-0.08 | 45-150 | 11 | 18930 | |

| WBL125-12 | 1250 | 12000 | 0.014-0.08 | 45-150 | 18.5 | 31898 | |

| WBL140-8 | 1400 | 8000 | 0.017-0.17 | ≤900 | 100-200 | 22 | 29298 |

| WBL140-16 | 140( | 16000 | 0.006-0.06 | ≤900 | 20-200 | 22 | 45999 |

| WBL150-5 | 1500 | 5000 | 0.014-0.08 | ≤700 | 85-288 | 15 | 18718 |

| WBL150-15 | 1500 | 15000 | 0.006-0.06 | ≤700 | 20-200 | 22 | 58800 |

| WBL150-10.5 | 1500 | 10500 | 0.006-0.06 | ≤700 | 20-200 | 22 | 49415 |

| WBL160-6 | 1600 | 6000 | 0.017-0.17 | ≤800 | 61-610 | 22 | 25032 |

| WBL160-9 | 1600 | 9000 | 0.076 | ≤800 | 180 | 22 | 34763 |

| WBL180-8 | 1800 | 8000 | 0.022-0.046 | ≤800 | 100-1000 | 37 | 53025 |

| WBL180-12 | 1800 | 12000 | 0.05 | ≤800 | 360 | 45 | 67806 |

| WBL220-10 | 2200 | 10000 | 0.018-0.055 | ≤1500 | 220-680 | 45 | 80400 |

| WBL240-10 | 2400 | 10000 | 0.018-0.055 | ≤1500 | 220-680 | 45 | 80400 |