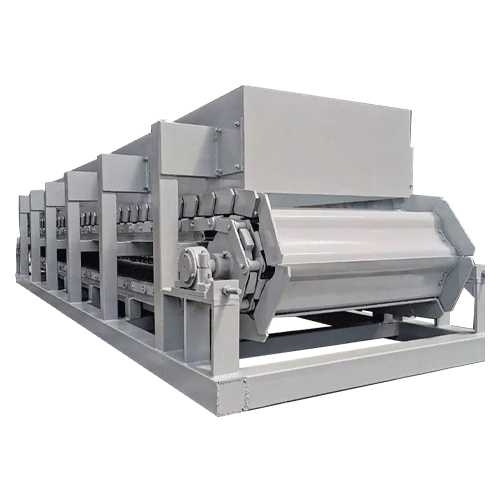

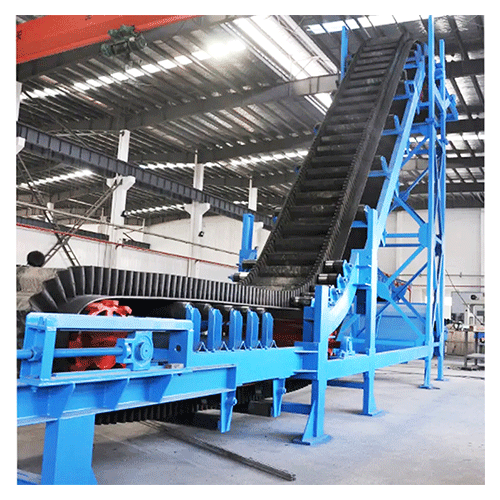

TGD型钢丝绳芯胶带斗式提升机

TGD TYPE STEEL RUBBER BELT BUCKET ELEVATOR

一、概述Summary

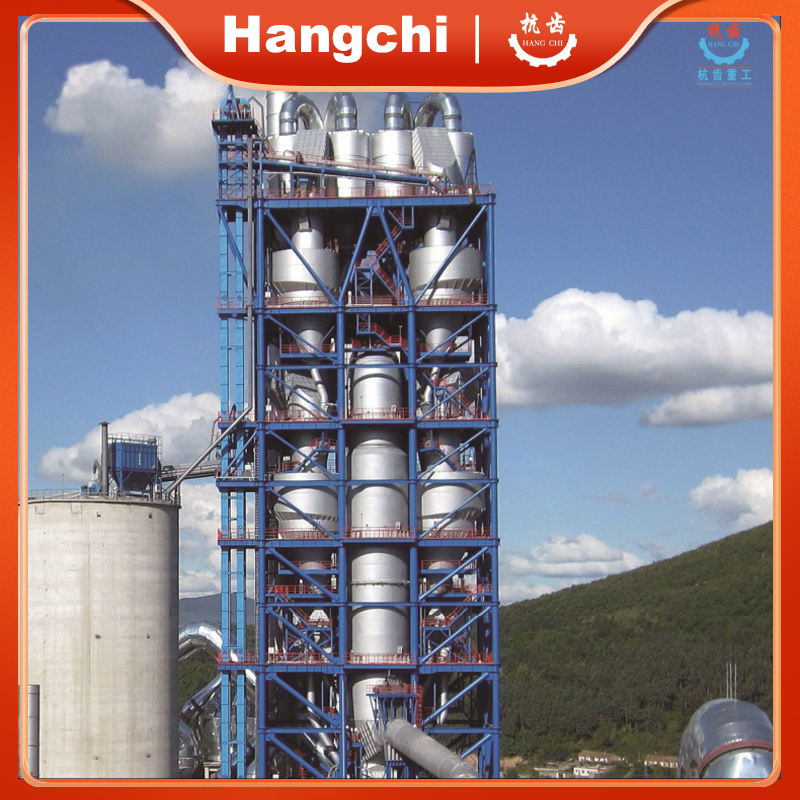

TGD型高效节能钢丝绳芯胶带斗式提升机,是我厂在总结现有各种型式提升机的基础上,吸收国外新技术,结合国内生产实际而研制开发的新产品,该机输送量大,提升高度高,提升高度高,消耗功率低,牵引件拉升强度高,韧性好、不延伸、耐磨损、使用寿命长,整机运行平稳、可靠;是当前比较理想的提升设备,该机不但适宜新厂建设使用,还可对现有的各种提升机进行内部同规格改造。

TGD型提升机适用于建材、冶金、化工、矿山等行业垂直提升粉状、粒状及小于30mm的块状且温度低于120℃的物料。

TGD type steel rubber belt bucket elevator is one newproduct. It has been designed through the introduction offoreign advanced technology and combining the actualsituation, This kind of machine has stable transmission andhigh lifting height low consumption, high tensile strength, high toughness, low elongation, good wear resistance, longservice life. So it is the ideal lifting equipment. This machineis not only ssuitable for new plant, but we also replace theold lifting machine through technical improvement.

TG type steel belt bucket elevator is used in building material industry, metallurgy, chemical, mining and other industries, it can vertically lift powder, graininess and blocky materials less than 30 mm, and the temperature of materials is not higher than 120℃.

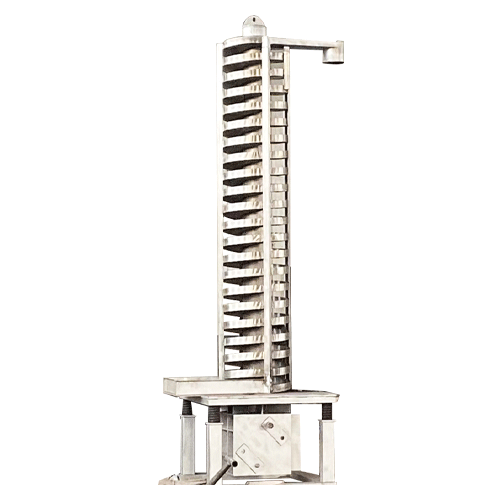

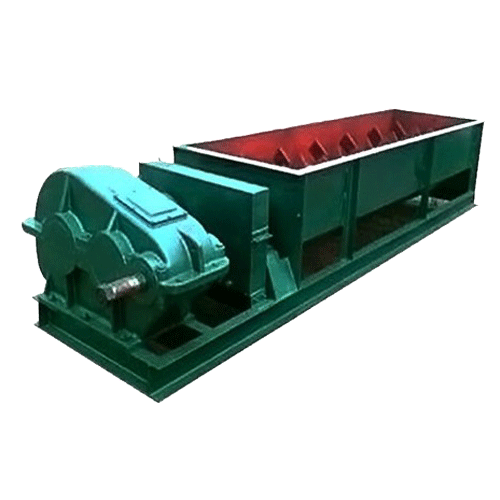

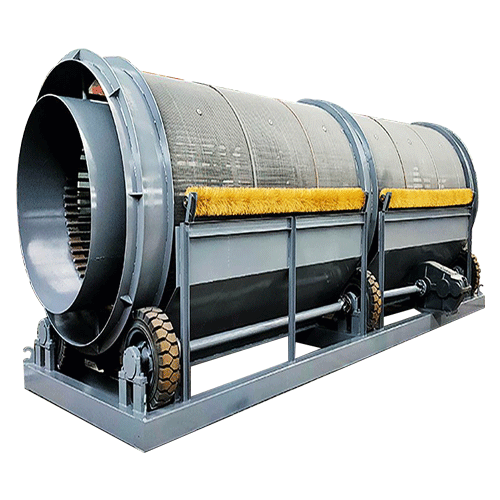

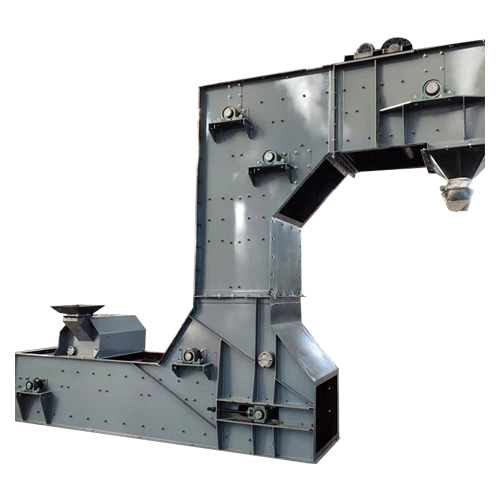

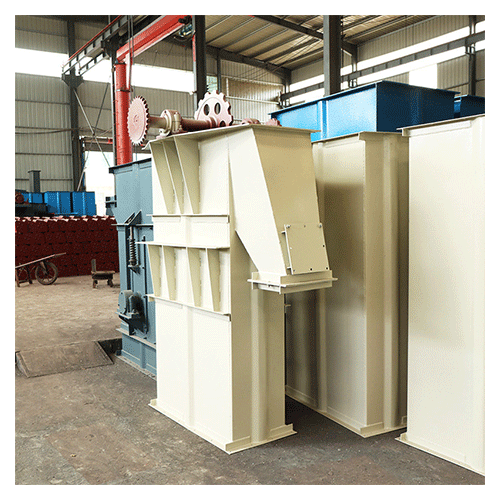

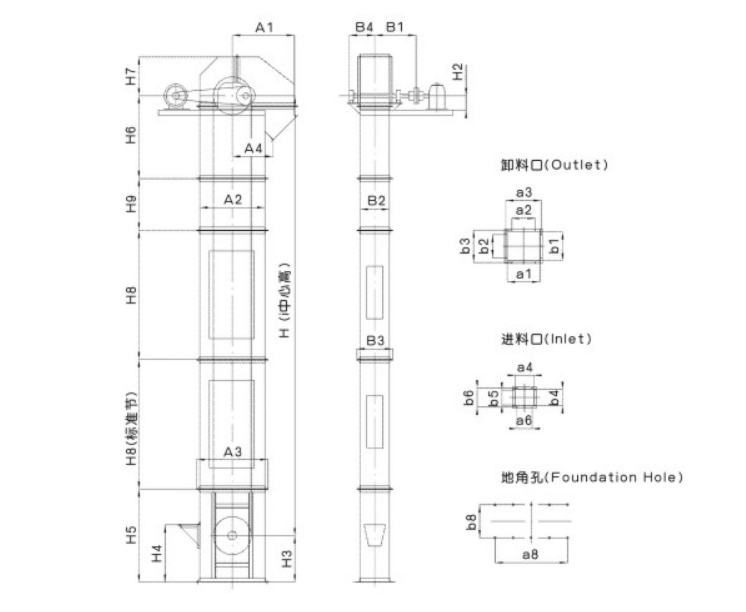

图4-1TGD315-TGD500外形结构图

Figure 4-1 TGD315-TGD500Outside View

二、主要技术参数 The Main Technical Parameters

表4-1TGD型斗式提升机主要技术参数

Table 4-1TGD Type Steel Rubber Belt Bucket Elevator Technical Par ameters Chart

| 规格型号 | TGD315 | TGD400 | TGD500 | TGD630 | TGD800 | TGD1000 |

| 斗宽(mm) | 315 | 400 | 500 | 630 | 800 | 1000 |

| 输送量φ=1(m³/h) | 86 | 123 | 176 | 259 | 351 | 486 |

| 斗容(L) | 6 | 9.5 | 15 | 24 | 38 | 60 |

| 输送量φ=1(m³/h) | 116 | 164 | 233 | 339 | 454 | 666 |

| 斗容(L) | 7.2 | 11.4 | 18 | 28.8 | 45.6 | 72 |

| 提升速度(m/s) | 1.7-1.9 | 1.7-1.9 | 1.7-1.9 | 1.7-1.9 | 1.7-1.9 | 1.7-1.9 |

| 最高提升高度(m) | 60 | 60 | 60 | 50 | 40 | 40 |

注:Ψ=1表示按料斗充满100%时的输送量。

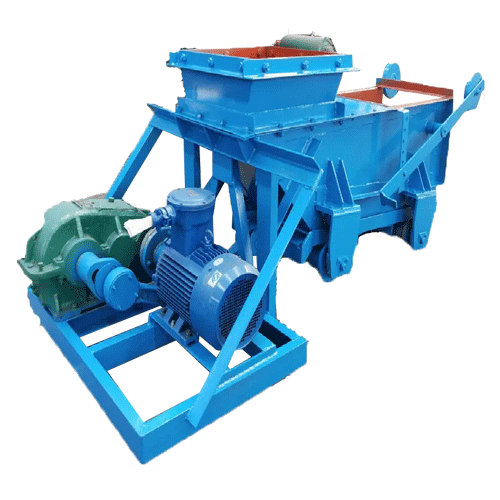

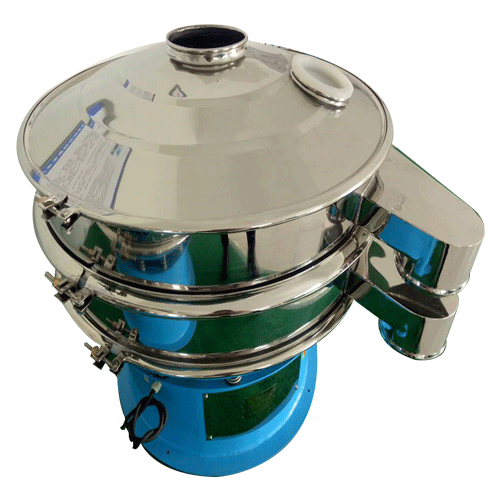

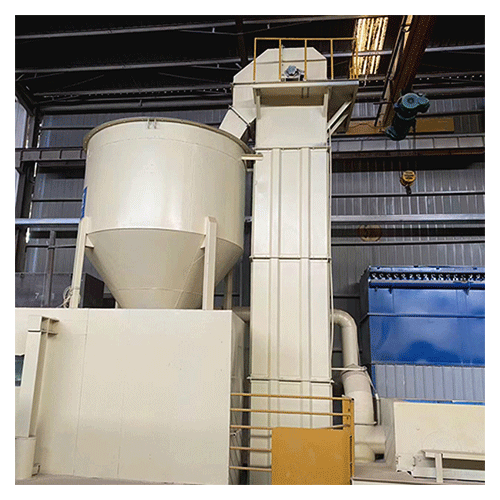

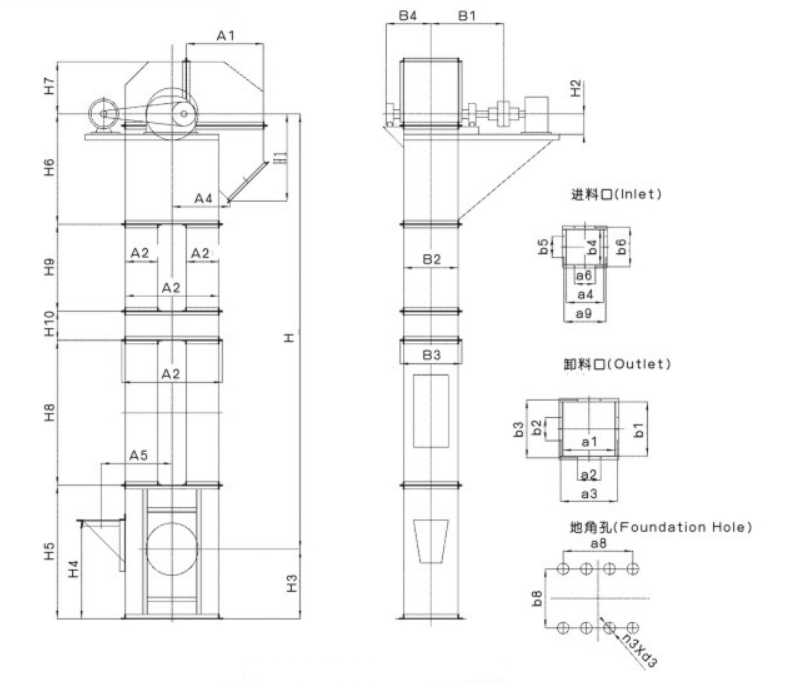

图4-2 TGD630-TGD1000外形结构图

Figure 4-2 TGD630-TGD1000 Outside View

三、外形及结构参数Technical Parameters And Outside View

外形结构见图4-1,图4-2,外形尺寸及动力参数见表4-2

表4-2TGD型斗式提升机外形尺寸及动力参数表

Table 4-2 TGD Type Steel Rubber Belt Bucket Elevator Profile Dim.

And Power Parameters Chart

| 代号 规格 |

机体部分(mm) Body |

|||||||||||||||||||||||||||||||

| A₁ | A₂ | (A₂) | A₃ | A₄ | A₅ | B₁ | B₂ | B₃ | B₄ | H₁ | H₂ | H₃ | H₄ | H₅ | H₆ | H₇ | H₈ | H₉ | ||||||||||||||

| TGD315 | 1203 | 1256 | 1382 | 790 | 549 | 566 | 392 | 415 | 850 | 280 | 900 | 1110 | 1800 | 1600 | 750 | 2500 | ||||||||||||||||

| TGD400 | 1304 | 1358 | 1484 | 850 | 623 | 668 | 794 | 462 | 1200 | 300 | 950 | 1250 | 1900 | 1600 | 810 | 2500 | ||||||||||||||||

| TGD500 | 1383 | 1468 | 1594 | 910 | 748 | 768 | 894 | 540 | 1300 | 325 | 1060 | 1460 | 2100 | 1700 | 880 | 2500 | ||||||||||||||||

| TGD630 | 1578 | 1608 | 558 | 1734 | 1000 | 420 | 825 | 938 | 1064 | 660 | 1500 | 350 | 1200 | 1700 | 2300 | 1900 | 900 | 2500 | 500 | |||||||||||||

| TGD800 | 1758 | 1810 | 610 | 1950 | 1100 | 500 | 930 | 1110 | 1250 | 750 | 1600 | 380 | 1350 | 1900 | 2400 | 2100 | 940 | 2500 | 600 | |||||||||||||

| TGD1000 | 1938 | 2010 | 670 | 2150 | 1200 | 600 | 1040 | 1310 | 1450 | 860 | 1700 | 415 | 1500 | 2100 | 2500 | 2300 | 1000 | 2500 | 800 | |||||||||||||

| 代号 规格 |

卸料口(mm) Outlet |

进料口(mm) Inlet |

地脚孔(mm) Foundation Hole |

|||||||||||||||||||||||||||||

| a₁ | a₂ | a₃ | b₁ | b₂ | b₃ | n₁ | d₁ | a₄ | a₅ | a₆ | a₇ | a₉ | b₄ | b₅ | b₆ | n₂ | d₂ | a₈ | b₉ | n₃ | d₃ | |||||||||||

| TGD315 | 630 | 2×225 | 686 | 560 | 2×225 | 626 | 12 | 14 | 355 | 70 | 2×145 | 25 | 315 | 2×145 | 375 | 19 | 14 | 3×350 | 638 | 8 | 26 | |||||||||||

| TGD400 | 710 | 2×250 | 790 | 600 | 2×250 | 740 | 12 | 14 | 450 | 95 | 2×180 | 30 | 375 | 2×180 | 445 | 9 | 14 | 3×400 | 740 | 8 | 26 | |||||||||||

| TGD500 | 800 | 3×220 | 880 | 760 | 3×220 | 840 | 16 | 14 | 560 | 140 | 3×210 | 30 | 475 | 2×220 | 545 | 9 | 14 | 4×360 | 846 | 10 | 26 | |||||||||||

| TGD630 | 900 | 4×200 | 980 | 930 | 4×200 | 1100 | 20 | 14 | 640 | 3×180 | 720 | 600 | 3×180 | 680 | 16 | 14 | 4×400 | 1018 | 10 | 32 | ||||||||||||

| TGD800 | 1000 | 5×200 | 1080 | 1100 | 5×200 | 1180 | 24 | 14 | 800 | 4×180 | 880 | 760 | 4×180 | 840 | 20 | 14 | 5×350 | 1190 | 12 | 32 | ||||||||||||

| TGD1000 | 1000 | 5×200 | 1080 | 1300 | 6×200 | 1380 | 26 | 14 | 1000 | 5×180 | 1080 | 880 | 4×200 | 960 | 22 | 14 | 5×360 | 1390 | 12 | 32 | ||||||||||||

| 代号 规格 |

传动装置(mm) Driving Unit |

|||||||||||||||||||||||||||||||

| 电动机(kw) | 减速机 | A6 | (A6) | B5 | (B5) | B6 | 电动机(kw) | 减速机 | A6 | (A6) | B5 | (B5) | B6 | |||||||||||||||||||

| Y132M-4(7.5) | ZLY140-20 | 610 | 620 | 400 | 50 | 275 | Y225S-4(37) | ZSY280-28 | 680 | 1290 | 660 | 70 | 555 | |||||||||||||||||||

| Y160M-4(11) | ZLY160-20 | 620 | 650 | 460 | 80 | 310 | Y225M-4(45) | DCY280-28 | 1460 | 440 | ||||||||||||||||||||||

| PY160L-4(15) | ZLY180-20 | 660 | 770 | 510 | 95 | 350 | Y250M-4(55) | DCY315-315.5 | 1615 | 510 | ||||||||||||||||||||||

| Y180M-4(18.5) | ZLY200-20 | 690 | 860 | 550 | 100 | 385 | Y280S-4(75) | DCY355-31.5 | 1795 | 585 | ||||||||||||||||||||||

| Y180L-4(22) | ZLY21-25 | 700 | 1040 | 560 | 90 | 430 | Y280S-4(90) | DCY400-31.5 | 1945 | 605 | ||||||||||||||||||||||

| Y200L-4(30) | ZLY250-25 | 710 | 1160 | 610 | 100 | 450 | Y315S-4(110) | DCY400-35.5 | 2005 | 605 | ||||||||||||||||||||||

注:表中给出的动力参数及传动装置配置供参考,可根据实际情况和用户要求予以调整。