<

>

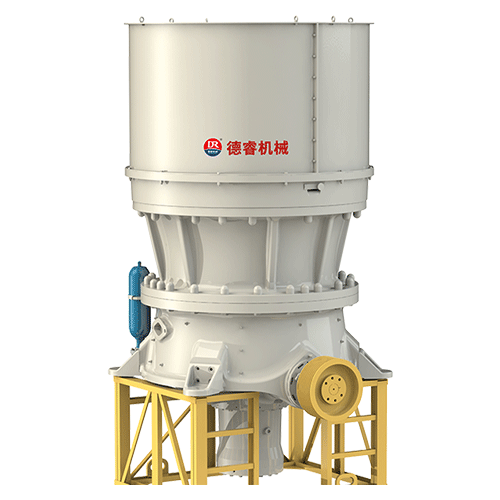

Single-cylinder Hydraulic Cone Crusher

Model:

PYY100

Maximum Feed Size:

120mm

Throughput:

35-135t/h

Total Weight:

5800kg

COLLECT

Shenyang Guangzhong Mining Machinery Equipment Co., Ltd

Main Products:Single cylinder crusher, multi cylinder crusher, spring cone crusher, jaw crusher, sand making machine

Enter the store

Details Parameters

Related product recommendations

More Products >

Shenyang Huatian Heavy Machinery Co., Ltd

Henan Liming Heavy Industry Technology Co., Ltd

Shenyang Henuode Machinery Equipment Co., Ltd

Fujian Derui Industrial Technology Group Co., Ltd.

微信图片_202111161411161.png)

lQDPJxao3EKSoEvNA3bNB4CwQanrU4panT4DFbonGYAGAA_1920_886.png)

.png)

.png)

单缸液压圆锥破碎机.png)