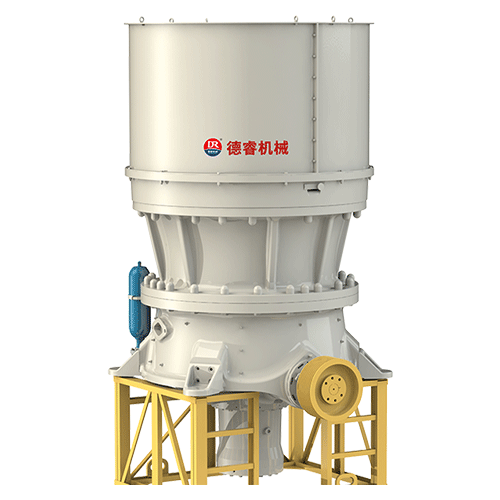

Product Introduction

SCH/SCS series and SGP single cylinder cone crushers developed and manufactured by our company are currently the most advanced and efficient single cylinder cone crushers in the world. It targets the high-end mining and building materials market, combining advanced mechanical, electrical, PLC, and hydraulic lubrication technologies to achieve perfect crushing efficiency as a whole. This series of single cylinder cone crushers adopts a sturdy cast steel frame, forged alloy spindle, high-precision circular arc gear transmission system, combined with multiple crushing chamber selections and PLC automatic control system, ASRI automatic repair system, fully exerting its excellent performance and advantages. Widely used for fine and coarse crushing of various stones and minerals.

Product Features

l High production efficiency

The scientifically designed crushing chamber, large eccentricity, high swing frequency, layered crushing, and hydraulic controlled constant pressure crushing force make the work more stable, with greater throughput capacity, higher production efficiency, better product shape, and minimized energy consumption.

l High automation

The PLC automatic control system can achieve monitoring functions such as overload protection, over iron protection, discharge adjustment, box cleaning, oil temperature, pressure, flow rate, and machine load discharge port size. To ensure the stable operation of the machine.

l High load capacity

Enhanced host frame, spindle adopts free support beam structure, copper sleeve with liquid lubrication design, sensitive and reliable overload protection system, ensuring long-term stable operation of the equipment in any working environment.

l Low installation cost

The SCH/SCS/SGP single cylinder crusher adopts a composite cup-shaped piston design, which reduces the installation height. The overall steel frame structure is convenient for installation, saving time and cost.

l Wide adaptability

There are two types of SCH/SCS/SGP single cylinder cone crushers: mid section crushing and fine crushing. Each type has various crushing chamber types to choose from. By adjusting the eccentricity, it is possible to adapt to different processing speeds and equipment capacities. By adjusting the size of the discharge port to regulate the grading of finished products, the equipment utilization rate can be maximized.

l Low operating costs

Specially designed cavities, village boards, support rings, and materials ensure high equipment utilization, long lining life, low operating costs, and short downtime. This machine is equipped with a positive pressure dust prevention system, which can keep the lubrication system clean without the need for oil seals or manual maintenance. Accessories can be disassembled and assembled from the top and side, saving time and effort in equipment maintenance.

l Low operating noise and minimal vibration

The circular arc gear transmission structure has high precision, low operating noise, high speed, and long service life. The host itself has low vibration, and the overall steel frame elastic support minimizes the amplitude, saving foundation costs.

Technical Parameter

|

SCH CRUSHER |

Power kw |

Basis Weight |

Normal Capacity(t/h) |

|||||||||||||||||

|

Maximum Feed Size mm |

4 |

6 |

8 |

10 |

13 |

16 |

19 |

22 |

-25f |

32 |

30 |

44 |

51 |

57 |

64 |

70 |

||||

|

SCH420 |

90 |

5300kg |

EC |

135 |

— |

— |

— |

45 |

50-85 |

54-92 |

85-99 |

62-105 |

66-112 |

76-123 |

— |

— |

— |

— |

— |

— |

|

C |

90 |

— |

— |

— |

43-53 |

45-89 |

50-95 |

54-103 |

57-110 |

61-118 |

70 |

— |

— |

— |

— |

— |

— |

|||

|

M |

65 |

— |

— |

36-44 |

38-74 |

41-80 |

45-76 |

45-59 |

— |

— |

— |

— |

— |

— |

— |

— |

— |

|||

|

MF |

50 |

— |

35 |

38-67 |

40-71 |

44-68 |

47-53 |

— |

— |

— |

— |

— |

— |

— |

— |

— |

— |

|||

|

F |

38 |

27-34 |

29-50 |

31-54 |

32-57 |

35-48 |

38 |

— |

— |

— |

— |

— |

— |

— |

— |

— |

— |

|||

|

EF |

29 |

30-40 with 80% finer than 4.5-5.5mm |

||||||||||||||||||

|

SCH430 |

112 |

9200kg |

EC |

185 |

— |

— |

— |

— |

69-108 |

75-150 |

80-161 |

86-171 |

91-182 |

104-208 |

115-206 |

— |

— |

— |

— |

— |

|

C |

145 |

— |

— |

— |

— |

66-131 |

71-142 |

76-152 |

81-162 |

86-173 |

98-197 |

109-150 |

— |

— |

— |

— |

— |

|||

|

MC |

115 |

— |

— |

— |

57 |

62-140 |

57-151 |

72-162 |

77-177 |

82-184 |

93-145 |

— |

— |

— |

— |

— |

— |

|||

|

M |

90 |

— |

— |

— |

64-84 |

69-131 |

75-142 |

80-152 |

86-162 |

91-154 |

104 |

— |

— |

— |

— |

— |

— |

|||

|

MF |

5 |

— |

— |

61 |

65-105 |

70-115 |

76-124 |

81-126 |

87-114 |

92 |

— |

— |

— |

— |

— |

— |

— |

|||

|

F |

50 |

— |

48-78 |

51-83 |

54-88 |

59-95 |

53-103 |

68-105 |

72-95 |

77 |

— |

— |

— |

— |

— |

— |

— |

|||

|

EF |

35 |

30-40 with 80% finer than 4.5-5.5mm |

||||||||||||||||||

|

SCH440 |

220 |

14300kg |

EC |

215 |

— |

— |

— |

— |

|

114-200 |

122-276 |

131-294 |

139-313 |

159-357 |

175-395 |

— |

— |

— |

— |

— |

|

C |

175 |

— |

— |

— |

— |

101 |

109-210 |

117-292 |

125-312 |

133-332 |

151-378 |

167-335 |

— |

— |

— |

— |

— |

|||

|

MC |

140 |

— |

— |

— |

— |

97-122 |

105-262 |

113-282 |

120-301 |

128-320 |

146-328 |

161-242 |

— |

— |

— |

— |

— |

|||

|

M |

110 |

— |

— |

— |

— |

117-187 |

126-287 |

136-298 |

145-318 |

154-039 |

175-281 |

194 |

— |

— |

— |

— |

— |

|||

|

MF |

85 |

— |

— |

— |

114 |

124-227 |

134-245 |

144-263 |

153-281 |

163-299 |

186-248 |

— |

— |

— |

— |

— |

— |

|||

|

F |

70 |

— |

— |

90-135 |

95-175 |

104-191 |

112-206 |

120-221 |

129-236 |

138-251 |

156-208 |

— |

— |

— |

— |

— |

— |

|||

|

EF |

38 |

100-125 with 80% finer than 6-7.5mm |

||||||||||||||||||

|

SCH650 |

315 |

26800kg |

EC |

275 |

— |

— |

— |

— |

— |

177 |

150-338 |

203-436 |

216-454 |

246-547 |

272-605 |

298-662 |

328-511 |

— |

— |

— |

|

CX |

245 |

— |

— |

— |

— |

— |

174-194 |

187-374 |

200-488 |

212-519 |

242-592 |

268-654 |

293-521 |

323-359 |

— |

— |

— |

|||

|

C |

215 |

— |

— |

— |

— |

— |

171-190 |

184-367 |

196-480 |

209-510 |

238-582 |

263-643 |

288-512 |

317-353 |

— |

— |

— |

|||

|

MC |

175 |

— |

— |

— |

— |

— |

162-253 |

174-426 |

186-455 |

190-484 |

226-552 |

249-499 |

273-164 |

— |

— |

— |

— |

|||

|

M |

135 |

— |

— |

— |

— |

— |

197-295 |

211-440 |

226-470 |

240-530 |

274-502 |

302-403 |

— |

— |

— |

— |

— |

|||

|

MF |

115 |

— |

— |

— |

— |

192 |

207-369 |

222-396 |

237-423 |

262-450 |

287-451 |

318-363 |

— |

— |

— |

— |

— |

|||

|

F |

85 |

— |

— |

— |

— |

195-304 |

210-328 |

225-352 |

241-376 |

256-400 |

292-401 |

323 |

— |

— |

— |

— |

— |

|||

|

EF |

65 |

— |

— |

— |

— |

211-293 |

227-316 |

244-298 |

261-290 |

— |

— |

— |

— |

— |

— |

— |

— |

|||

|

SCH870 |

500 |

45800kg |

EC |

300 |

— |

— |

— |

— |

— |

— |

— |

448-588 |

477-849 |

544-968 |

601-1070 |

658-1172 |

725-1291 |

782-1393 |

849-1512 |

906-1331 |

|

C |

240 |

— |

— |

— |

— |

— |

— |

406 |

433-636 |

461-893 |

525-1018 |

501-1125 |

636-1232 |

700-1357 |

756-1464 |

820-1461 |

876-1286 |

|||

|

MC |

195 |

— |

— |

— |

— |

— |

— |

380-440 |

406-723 |

432-837 |

492-954 |

544-1055 |

556-1155 |

657-1272 |

708-1373 |

769-1370 |

821-1206 |

|||

|

M |

155 |

— |

— |

— |

— |

— |

— |

400-561 |

428-786 |

455-836 |

519-953 |

573-1054 |

628-1154 |

692-1271 |

746-1372 |

810-1248 |

865-1098 |

|||

|

MF |

100 |

— |

— |

— |

— |

— |

379-424 |

407-716 |

434-765 |

452-814 |

527-928 |

852-942 |

618-789 |

702 |

— |

— |

— |

|||

|

F |

90 |

— |

— |

— |

— |

357-395 |

385-656 |

414-704 |

442-752 |

470-800 |

535-912 |

592-857 |

649-718 |

— |

— |

— |

— |

|||

|

EF |

80 |

— |

— |

— |

280-405 |

304-517 |

328-558 |

352-598 |

376-639 |

400-680 |

455-775 |

503-128 |

551-669 |

— |

— |

— |

— |

|||

|

SCH CRUSHER |

Power kw |

Basis Weight |

Normal Capacity(t/h) |

||||||||||||||||||||

|

Maximum Feed Size mm |

10 |

19 |

22 |

26 |

28 |

32 |

36 |

38 |

41 |

44 |

40 |

51 |

54 |

57 |

60 |

64 |

70 |

78 |

83 |

||||

|

SCS420 |

90 |

6800kg |

EC |

240 |

— |

— |

102-116 |

108-144 |

115-154 |

121-162 |

127-145 |

132 |

— |

— |

— |

— |

— |

— |

— |

— |

— |

— |

— |

|

C |

200 |

77 |

82-110 |

87-116 |

92-123 |

99-113 |

103 |

— |

— |

— |

— |

— |

— |

— |

— |

— |

— |

— |

— |

— |

|||

|

SCS430 |

132 |

12000kg |

EC |

340 |

— |

— |

— |

151 |

161-245 |

169-257 |

176-289 |

134-281 |

192-292 |

200-304 |

210-281 |

218-250 |

225 |

— |

— |

— |

— |

— |

— |

|

C |

300 |

— |

— |

— |

170-198 |

182-77 |

191-290 |

199-304 |

208-217 |

217-330 |

226-203 |

237 |

— |

— |

— |

— |

— |

— |

— |

— |

|||

|

MC |

235 |

— |

— |

130 |

137-209 |

147-224 |

154-235 |

161-245 |

168-256 |

175-267 |

182-244 |

192 |

— |

— |

— |

— |

— |

— |

— |

— |

|||

|

SCS440 |

220 |

19300kg |

EC |

450 |

— |

— |

— |

— |

— |

— |

273-318 |

285-434 |

297-452 |

309-470 |

325-495 |

337-447 |

349-405 |

— |

— |

— |

— |

— |

— |

|

C |

440 |

— |

— |

— |

— |

— |

291 |

304-483 |

317-483 |

331-503 |

344-456 |

362-421 |

375 |

— |

— |

— |

— |

— |

— |

— |

|||

|

MC |

300 |

— |

— |

— |

— |

245 |

257-391 |

269-409 |

281-427 |

292-445 |

304-403 |

320-372 |

332 |

— |

— |

— |

— |

— |

— |

— |

|||

|

SCS660 |

315 |

35700kg |

EC |

680 |

— |

— |

— |

— |

— |

— |

— |

331-385 |

345-514 |

359-590 |

378-624 |

392-647 |

406-670 |

420-693 |

433-716 |

452-746 |

410-792 |

508-756 |

540 |

|

C |

600 |

— |

— |

— |

— |

— |

— |

335 |

350-454 |

364-602 |

379-628 |

399-658 |

415-683 |

428-707 |

443-731 |

458-755 |

477-710 |

507-589 |

— |

— |

|||

8.png)

6.png)

3.png)

2.png)

1.png)

单缸液压圆锥破碎机2.png)

单缸液压圆锥破碎机.png)