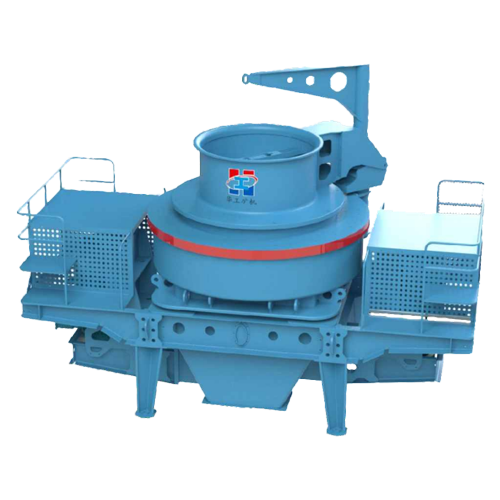

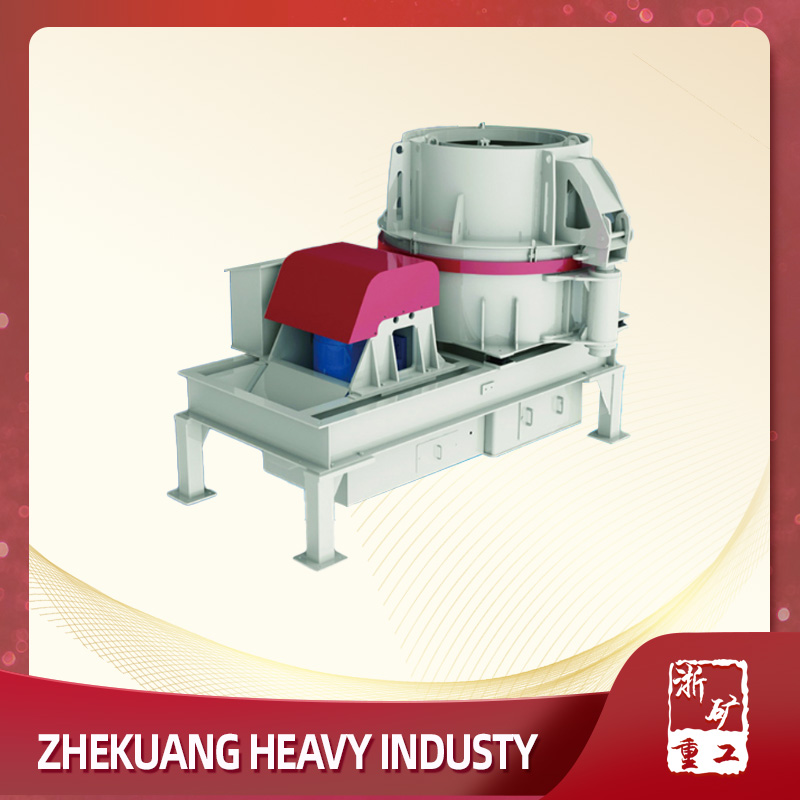

Product Introduction

SVSl series vertical axis impact crusher is a new type of crusher that our company has introduced the most advanced technology from Europe and America, which subverts traditional crusher theory and is highly welcomed by users. It has sparked a disruptive revolution in stone crushing and processing in China. The characteristics of a crusher are low operation, high cost, strong adaptability, large production capacity, good product appearance, and wide application range. It is one of the most competitive crushers in China. Currently, numerous SVSl series vertical impact crushers are working in different fields.

SVSI series vertical axis impact crusher is widely used for fine crushing and shaping minerals and rocks in various industries such as metal and non-metal mines, refractory, ceramic grinding media, building materials and highway construction, water conservancy and hydropower engineering, mechanism sand, aggregate production, etc. For superhard or corrosive raw materials such as sandstone, granite, basalt, diamond sand, bauxite, magnesia, etc., it has obvious advantages. The SVSI series vertical impact crusher adopts high-speed (80M/S or above) mode and can also be used for fine crushing and reshaping of coarse sand in the sand and aggregate processing industry to optimize particle size distribution and reduce the fineness modulus, achieving the overall effect of the machine.

Working principle

According to the different crushing environments and raw material conditions, two crushing structures, "stone to stone" and "stone to iron", can be selected by controlling the feeding method. 'Shi Da Shi' separates the feed into two streams through a cascade flow separation system. One stream enters the high-speed rotating rotor through the feed pipe, and the material is accelerated and discharged from the rotor port. Another stream enters the crusher chamber through the overflow gate of the feeding hopper. These two materials collide violently around the rotor. 'Shi Da Tie' is the process of introducing materials from the feed pipe into the inner cavity of the rotor, which is then accelerated and thrown by the high-speed rotating rotor. Outside the rotor, the material strongly impacts the impact plate installed on the crushing chamber wall. The "stone to stone" structure is generally used for processing hard materials, with a sand yield of about 40%; The "stone to iron" structure is generally used for processing medium hard materials, with a sand production rate of around 40% -60%.

Product Features

l Optional manual hydraulic pump can be used to regulate the flow to the impeller, while the ratio of the impeller feed flow to the string flow into the crushing chamber can be accurately controlled by adjusting the vertical position of the distributor plate.

l crusher can be equipped with optional suspended manual or electric hoist. During crusher maintenance, this lifting device can easily, conveniently lift the crusher top cover, feed hopper, distributor, rotor, spindle and so on.

l This device is designed as an option for this machine and turns it to the side after lifting from the hopper.

l The crusher has two types of crushing structure, "stone to stone" and "stone to iron", both of which can be converted in one crushing chamber by simple parts replacement to meet the needs of different crushing environments and raw materials.

Technical Parameter

Optional oil lubrication system and PLC control detection system can monitor feed rate, current, oil temperature, spindle temperature, and also achieve vibration protection function

|

SVSI |

SB5100SE |

SB6150SE |

SB7150SE |

SB9100SE |

||

|

Power |

37-55KW |

75-150KW |

185-300KW |

370-600KW |

||

|

Basic crusher weight |

3037kg |

6371kg |

12395kg |

14357kg |

||

|

Maximum feeding particle size |

32mm |

43mm |

58mm |

70mm |

||

|

Rotor speed |

1500-3600RPM |

1500-2500RPM |

1100-2000RPM |

1000-1800RPM |

||

|

Closed side setting |

Capacity |

|||||

|

Installed power |

Driver configuration |

|

|

|

|

|

|

37kw(50hp) |

Single motor |

Mtph |

19-40 |

|

|

|

|

Stph |

21-44 |

|

|

|

||

|

45kw(60hp) |

Single motor |

Mtph |

22-48 |

|

|

|

|

Stph |

24-53 |

|

|

|

||

|

55kw(75hp) |

Dual motor |

Mtph |

28-60 |

|

|

|

|

Stph |

31-66 |

|

|

|

||

|

75kw(100hp) |

Single motor |

Mtph |

|

44-103 |

|

|

|

Stph |

|

48-113 |

|

|

||

|

92kw(125hp) |

Single motor |

Mtph |

|

55-134 |

|

|

|

Stph |

|

60-147 |

|

|

||

|

110kw(150hp) |

Single motor |

Mtph |

|

66-168 |

|

|

|

Stph |

|

73-185 |

|

|

||

|

132kw(175hp) |

Single motor |

Mtph |

|

77-202 |

|

|

|

Stph |

|

85-222 |

|

|

||

|

150kw(200hp) |

Single motor |

Mtph |

|

100-217 |

|

|

|

Stph |

|

110-238 |

|

|

||

|

185kw(250hp) |

Single motor |

Mtph |

|

|

125-298 |

|

|

Stph |

|

|

137-327 |

|

||

|

220kw(300hp) |

Single motor |

Mtph |

|

|

150-378 |

|

|

Stph |

|

|

165-415 |

|

||

|

260kw(350hp) |

Dual motor |

Mtph |

|

|

175-460 |

|

|

Stph |

|

|

192-505 |

|

||

|

300kw(400hp) |

Dual motor |

Mtph |

|

|

200-545 |

|

|

Stph |

|

|

220-599 |

|

||

|

370kw(500hp) |

Dual motor |

Mtph |

|

|

|

263-629 |

|

Stph |

|

|

|

289-691 |

||

|

440kw(600hp) |

Dual motor |

Mtph |

|

|

|

315-725 |

|

Stph |

|

|

|

346-797 |

||

|

520kw(700hp) |

Dual motor |

Mtph |

|

|

|

368-765 |

|

Stph |

|

|

|

404-841 |

||

|

600kw(800hp) |

Dual motor |

Mtph |

|

|

|

420-775 |

|

Stph |

|

|

|

462-852 |

||

2.png)

8.png)

6.png)

3.png)

1.png)

8HL.png)

冲击式破碎机.png)