<

>

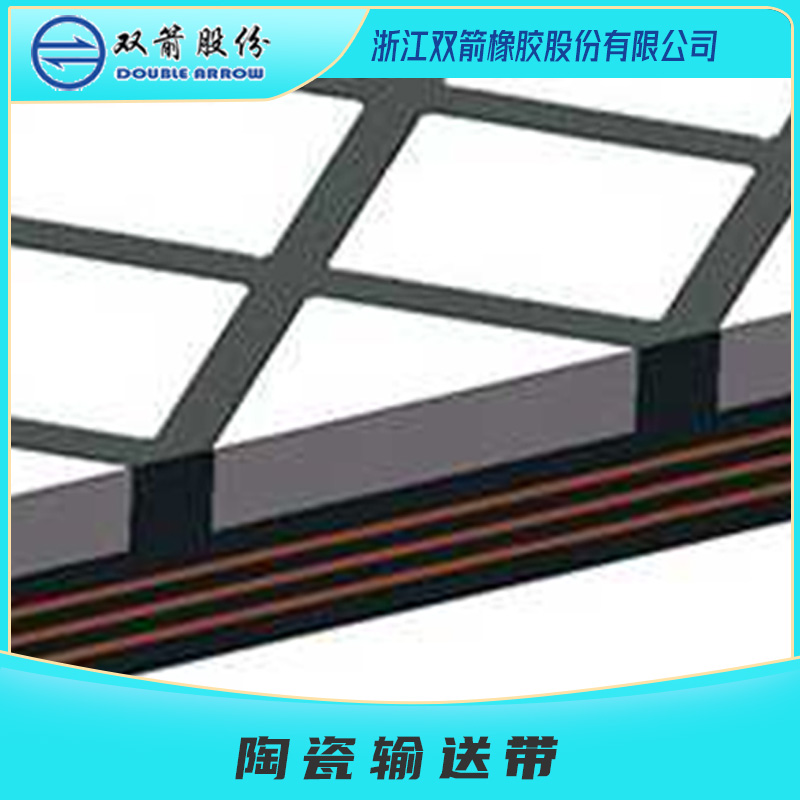

Ceramic conveyor belt

Type of Conveyor Belt:

Ceramic conveyor belt

Standard or Not:

According to customer's deman

Material Quality:

New Modified Ceramic

Model:

Ceramic conveyor belt

COLLECT

Zhejiang Shuangjian Rubber Co., Ltd

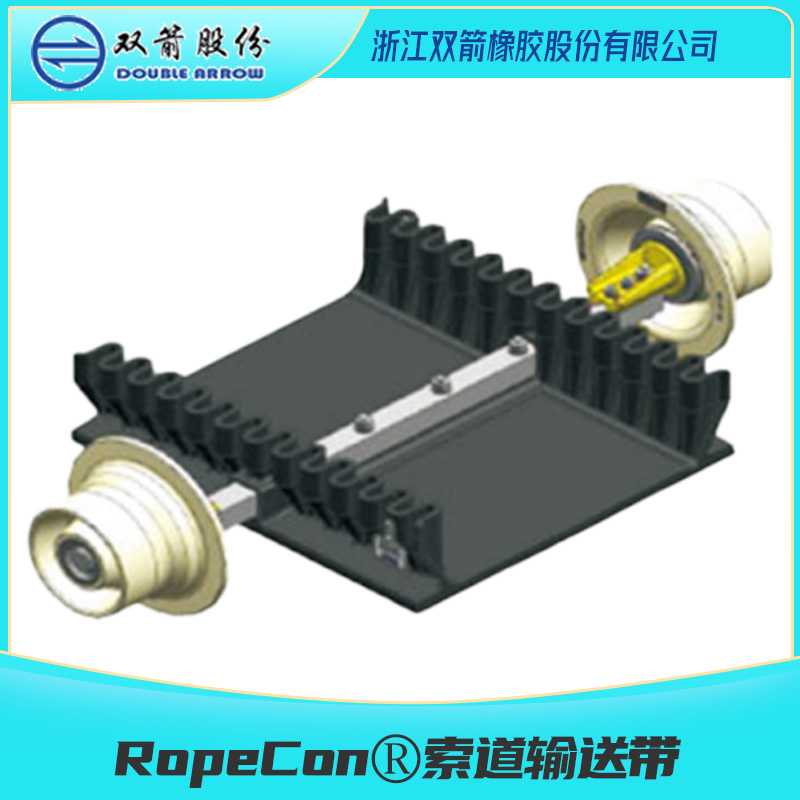

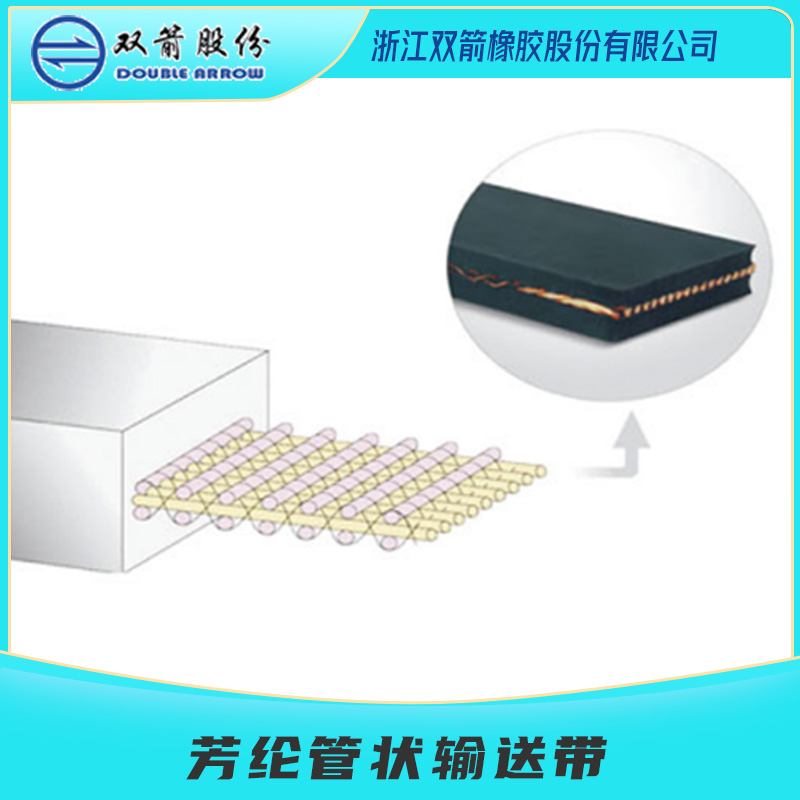

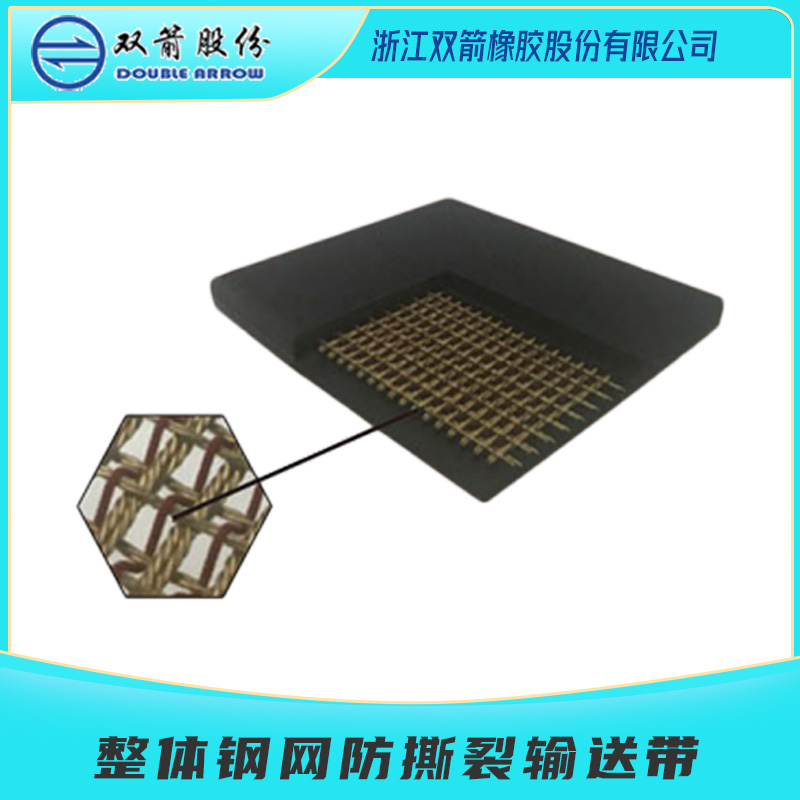

Main Products:Ordinary type, strong type (nylon, polyester, steel wire rope core), acid and alkali resistance, high temperature resistance, flame retardant, oil resistant, heat resistant, tear resistant, puncture resistant, food, pattern, tubular, edge blocking, flame retardant, cold resistant, energy-saving, aramid, PVC, PVG conveyor belt, MT668 coal mine underground steel wire rope conveyor belt, etc.

Enter the store

Details Parameters

Related product recommendations

More Products >

Zhejiang Shuangjian Rubber Co., Ltd

Zhejiang Shuangjian Rubber Co., Ltd

Zhejiang Shuangjian Rubber Co., Ltd

Zhejiang Shuangjian Rubber Co., Ltd

Zhejiang Shuangjian Rubber Co., Ltd