Main Applications:

Dry and wet magnetic separation of weak magnetic ores such as magnetite, vanadium-titanium magnetite, and titanomagnetite; dry iron removal from non-metallic ores. The separation efficiency is internationally leading.

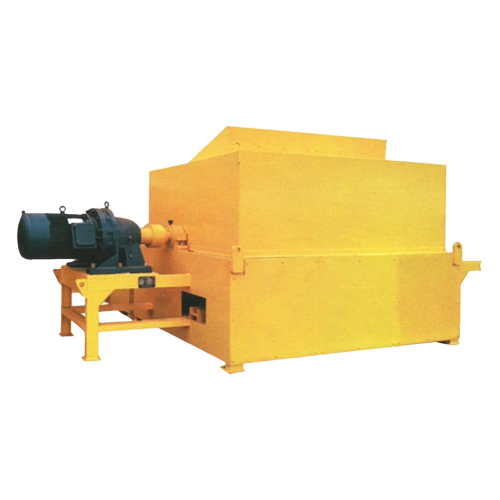

Technical Features:

Customized design of multi-gradient magnetic system with strong magnetic force and high processing capacity. The maximum single-machine processing capacity for dry magnetic separation is 600 tons/hour, with an equipment operating rate of up to 99% and maintenance-free operation. Excellent separation efficiency, well-controlled tailings, and concentrate free of impurities.

Structural Characteristics:

Depending on the model and performance of the magnetic separator, through-shaft or half-shaft designs are adopted to ensure normal equipment operation. The magnetic drum shell is made of wear-resistant stainless steel and surface-treated with calcined alumina wear-resistant ceramic tiles, guaranteeing no damage under normal use for 10 years. Wear-resistant treatment is applied to the worn parts of the body, ensuring no damage for 10 years under normal use. The transmission device adopts a pin-type coupling, effectively avoiding manufacturing defects during equipment processing and providing good centering. The power unit employs a variable-frequency adjustable motor, allowing for adjustment of separation indicators according to production needs.

Performance Characteristics & Advantages of Dry Magnetic Separator: High operating rate, excellent magnetic separation effect, concentrate free of impurities, and tailings free of ore.

Technical Parameters:

|

Serial Number |

Equipment Model |

Processing Capacity(t/h) |

Magnetic Drum (Diameter*Length)mm |

Magnetic Drum Configuration |

Total Power(kW) |

|

1 |

CTG1215 |

100 |

1200*1500 |

Single drum configuration |

23.5 |

|

2 |

CTG1218 |

120 |

1200*1800 |

Single drum configuration |

23.5 |

|

3 |

CTG1224 |

150 |

1200*2400 |

Single drum configuration |

23.5 |

|

4 |

CTG1230 |

200 |

1200*3000 |

Single drum configuration |

31.5 |

|

5 |

CTG1521 |

200 |

1500*2100 |

Single drum configuration |

32.2 |

|

6 |

CTG1524 |

250 |

1500*2400 |

Single drum configuration |

32.2 |

|

7 |

CTG1530 |

300 |

1500*3000 |

Single drum configuration |

39.2 |

|

8 |

CTG1830 |

400 |

1800*3000 |

Single drum configuration |

92.2 |

|

9 |

2CTG1230 |

400 |

1200*3000 |

Double drum parallel configuration |

64.4 |

|

10 |

2CTG1521 |

400 |

1500*2100 |

Double drum parallel configuration |

64.4 |

|

11 |

2CTG1524 |

500 |

1500*2400 |

Double drum parallel configuration |

64.4 |

|

12 |

2CTG1530 |

600 |

1500*3000 |

Double drum parallel configuration |

78.4 |